Hydraulic bracket assembling and disassembling machine with supporting upright column

A technology for supporting columns and hydraulic supports, which is applied to pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of time-consuming and labor-intensive work, high labor intensity of workers, and difficult adjustment of hydraulic supports, so as to speed up disassembly and assembly and save energy. The effect of reducing disassembly and assembly time and improving the mechanization level of fully mechanized mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

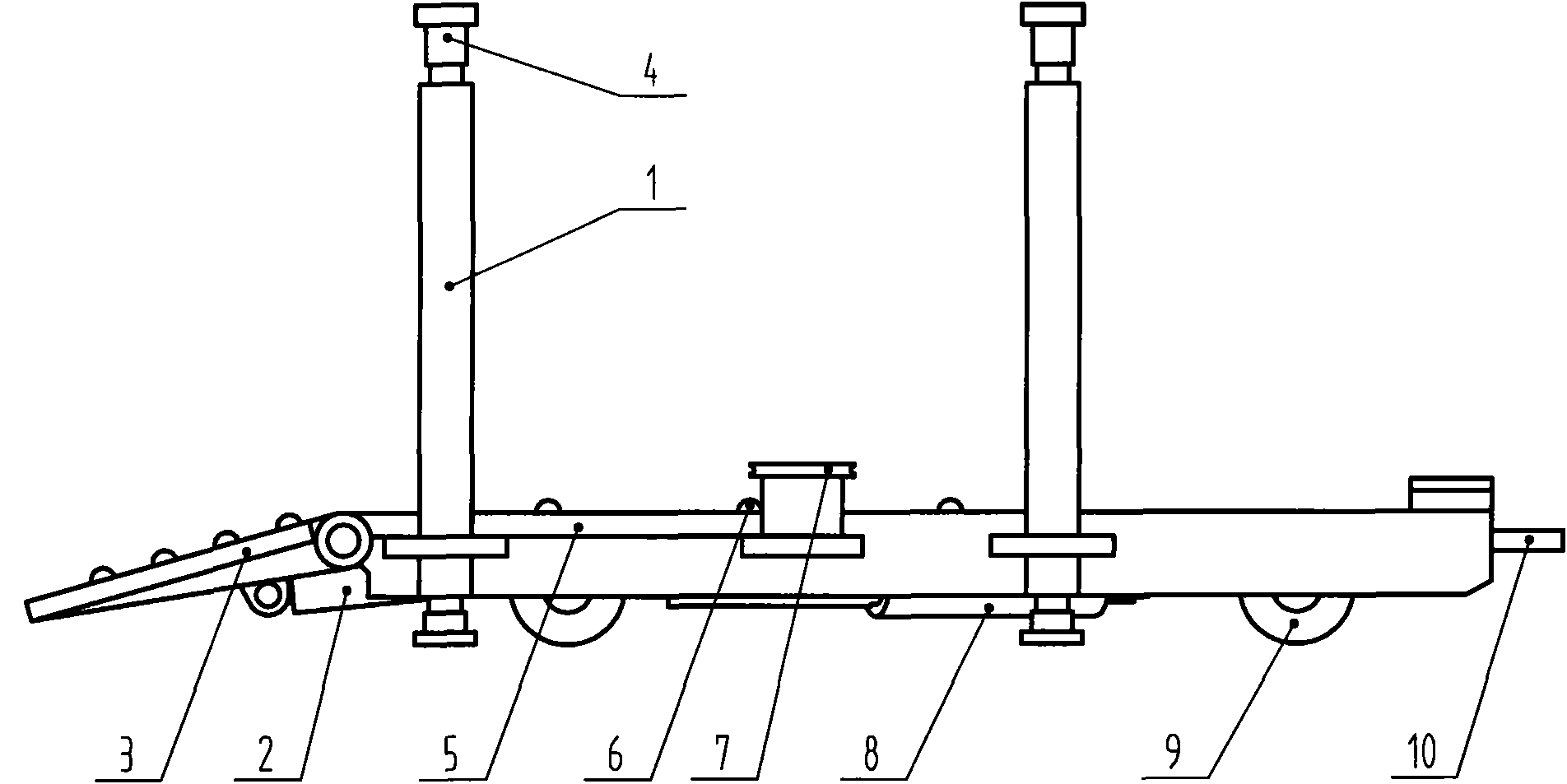

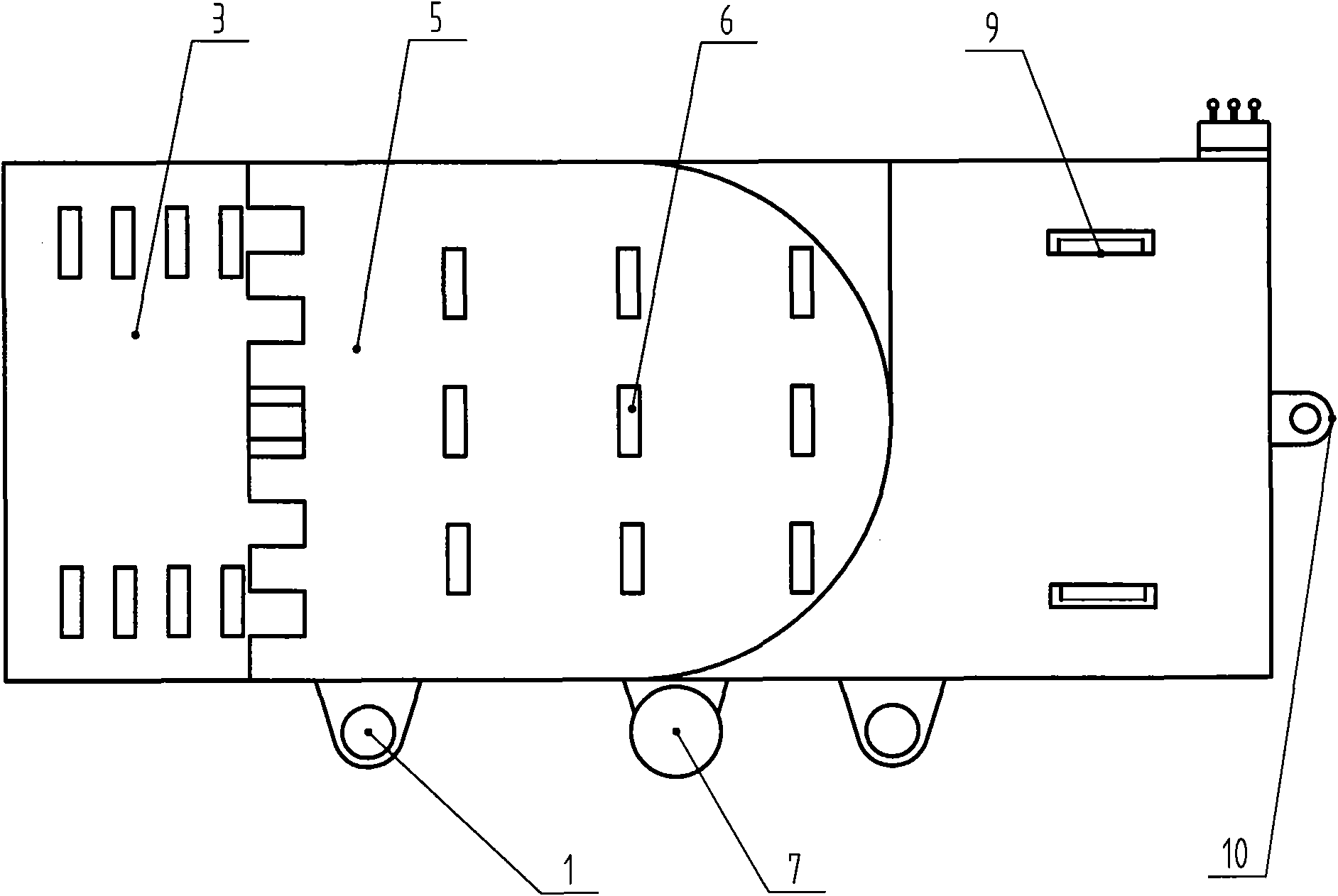

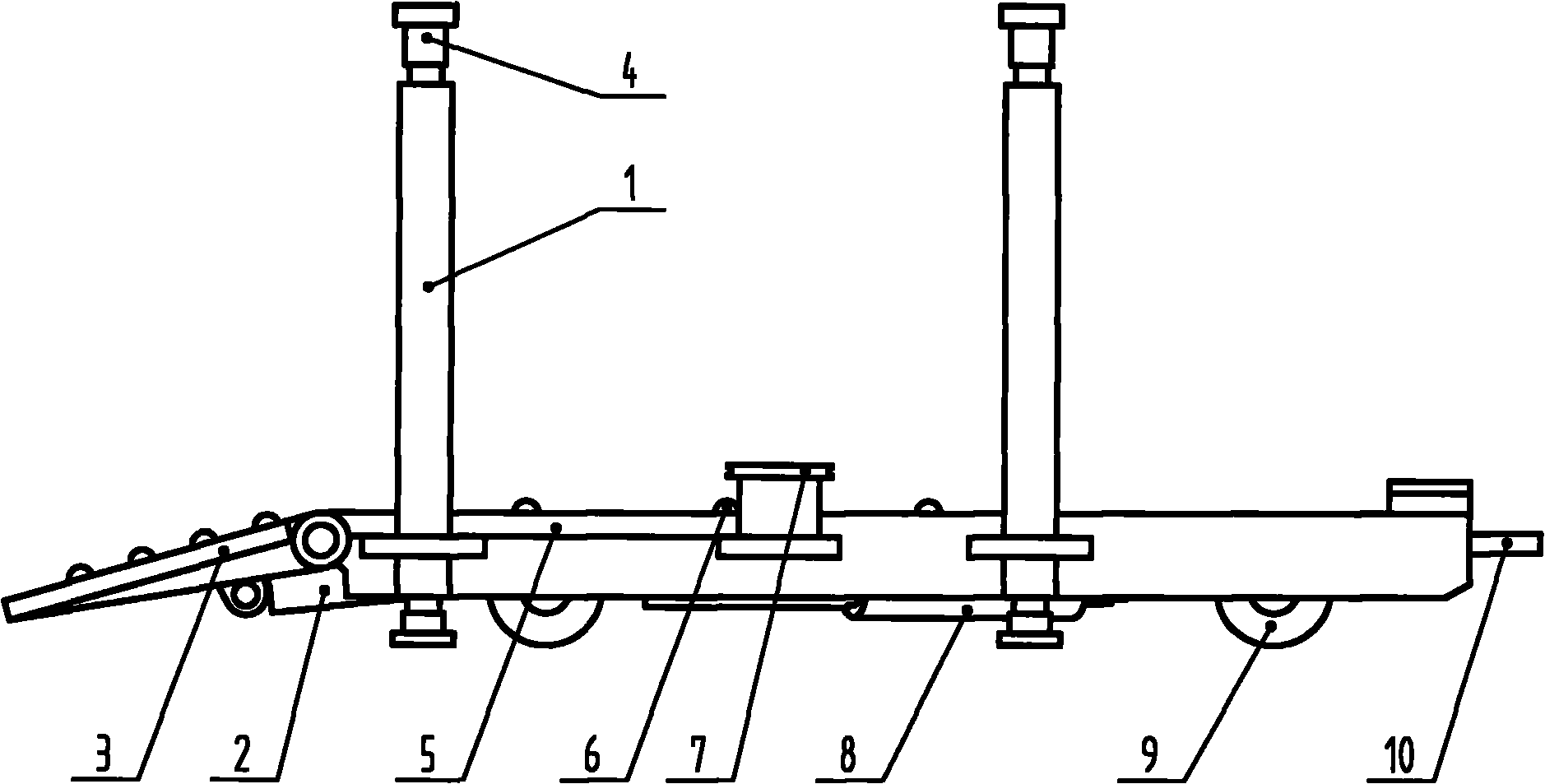

[0018] Such as figure 1 , figure 2 As shown, the rotating plate 5 is installed on the car body, and the outer end of the rotating plate 5 is hingedly connected with the lifting plate 3. The bottom is connected, and the cylinder body of rotary oil cylinder 8 is installed and fixed on the car body bottom, and the piston rod end of rotary oil cylinder 8 is connected to rotating plate 5 by crank, and two support columns 1 are vertically fixed on the two ends of a side of car body respectively.

[0019] The lower part of the car body is provided with 4 pulleys 9, one end of the car body is fixed with a pull ring 10, the rotating plate 5 is provided with 9 rollers 6, and the lifting plate 3 is provided with 8 rollers 6, between the two supporting columns 1 Between is fixed with the pulley 7 that laterally arranges.

[0020] The cylinder bodies of the same hydraulic cylinders 4 are respectively fixed on the upper parts of the two supporting columns 1, and the piston rods of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com