A method for reversely hauling trolleys in tunnels

A technology for trolleys in tunnels, which is applied in earthwork drilling, underground transportation, transportation and packaging, etc. It can solve the problems that trolleys cannot be received, separated and hoisted from narrow shield tunnels, so as to reduce construction costs and facilitate Towing, enhancing overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

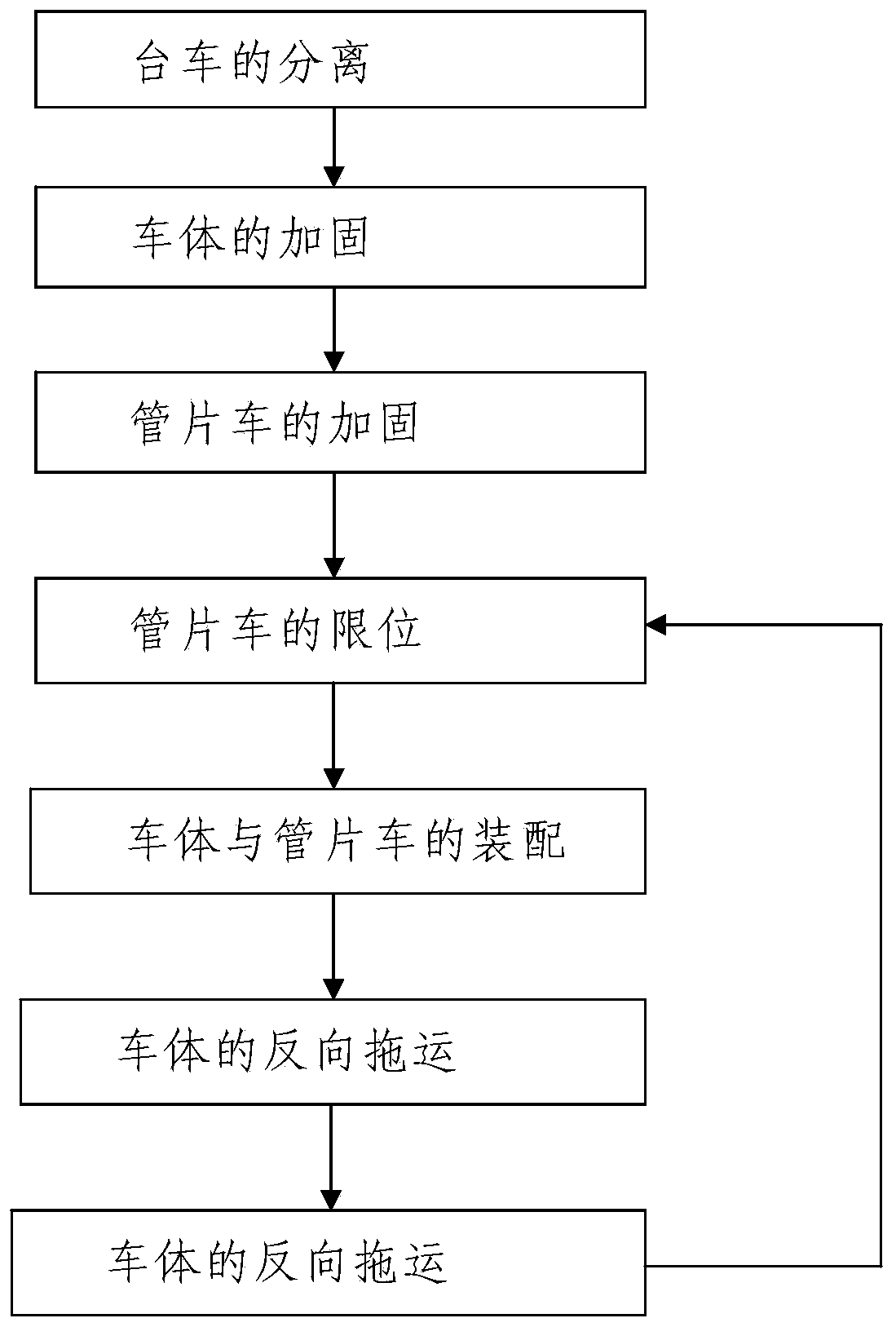

[0034] Such as figure 1 Shown is a method for reversely hauling trolleys in a tunnel, the method of the present invention comprises the following steps:

[0035] Step 1. Separation of the trolley: the trolley is split into multiple car bodies 3 in the tunnel, and the multiple car bodies 3 are arranged on the trolley guide rail 7-1 in sequence;

[0036] In this embodiment, the number of car bodies 3 is 6, and the 6 car bodies 3 are arranged on the trolley guide rail 7-1 in sequence, and the ones arranged in sequence along the direction of the receiving wellhead of the shield machine to the starting wellhead of the shield machine are number one respectively. Hull, No. 2, No. 3, No. 4, No. 5, and No. 6.

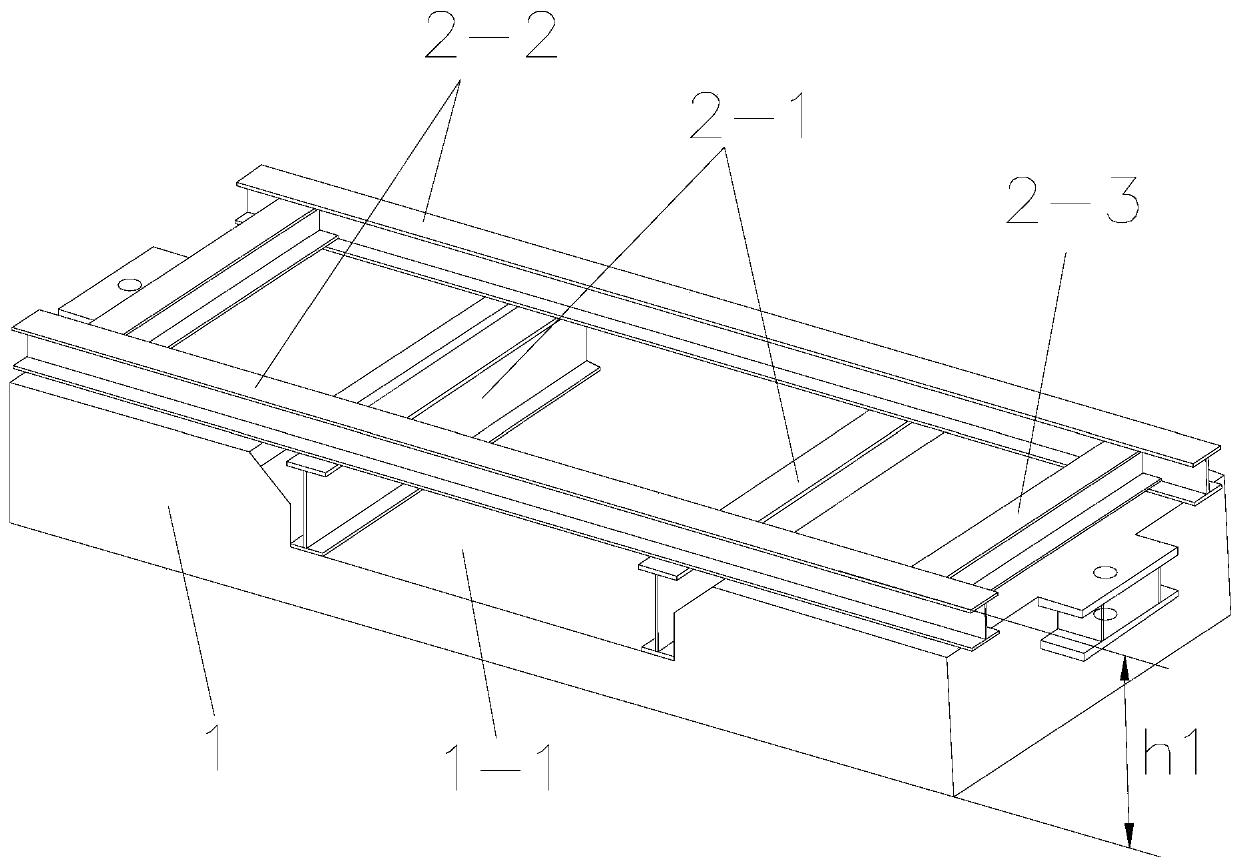

[0037] Step 2. Reinforcement of the car body: if figure 2 As shown, a first reinforcement rod 4-1 and a second reinforcement rod 4-2 are installed between the bottom of the car body 3;

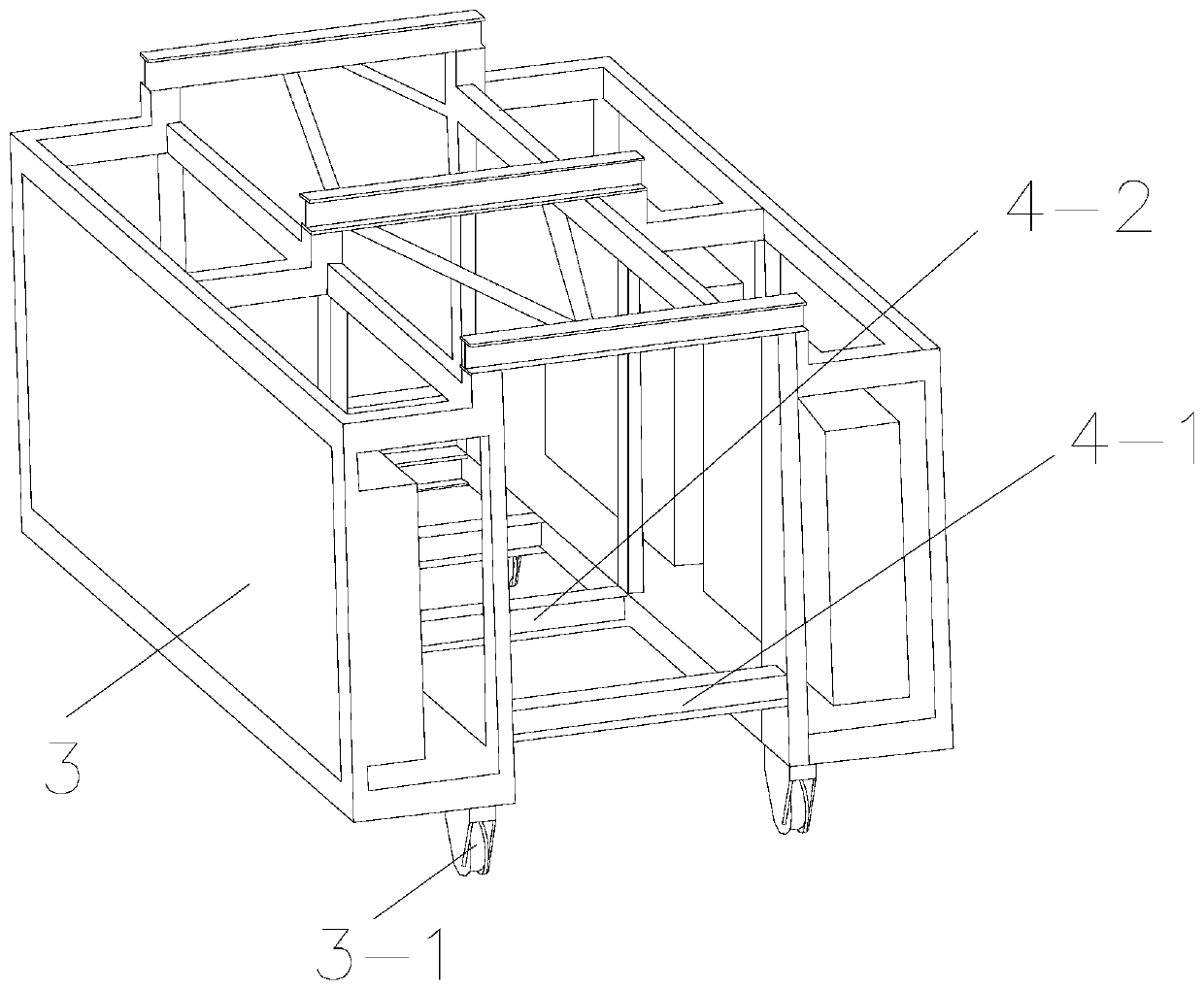

[0038] In actual use, when the car body 3 needs to be assembled on the segment car 1, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com