Oil cylinder lifting type isolating valve special for vacuum induction furnace

A vacuum induction furnace and isolation valve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve unfavorable equipment production and use, inflatable sealing rubber ring material quality, high manufacturing precision requirements, machining and assembly design Calculation of unreliable dynamic seals and other issues to achieve the effect of eliminating heat radiation and heat conduction, simple and reliable structure, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

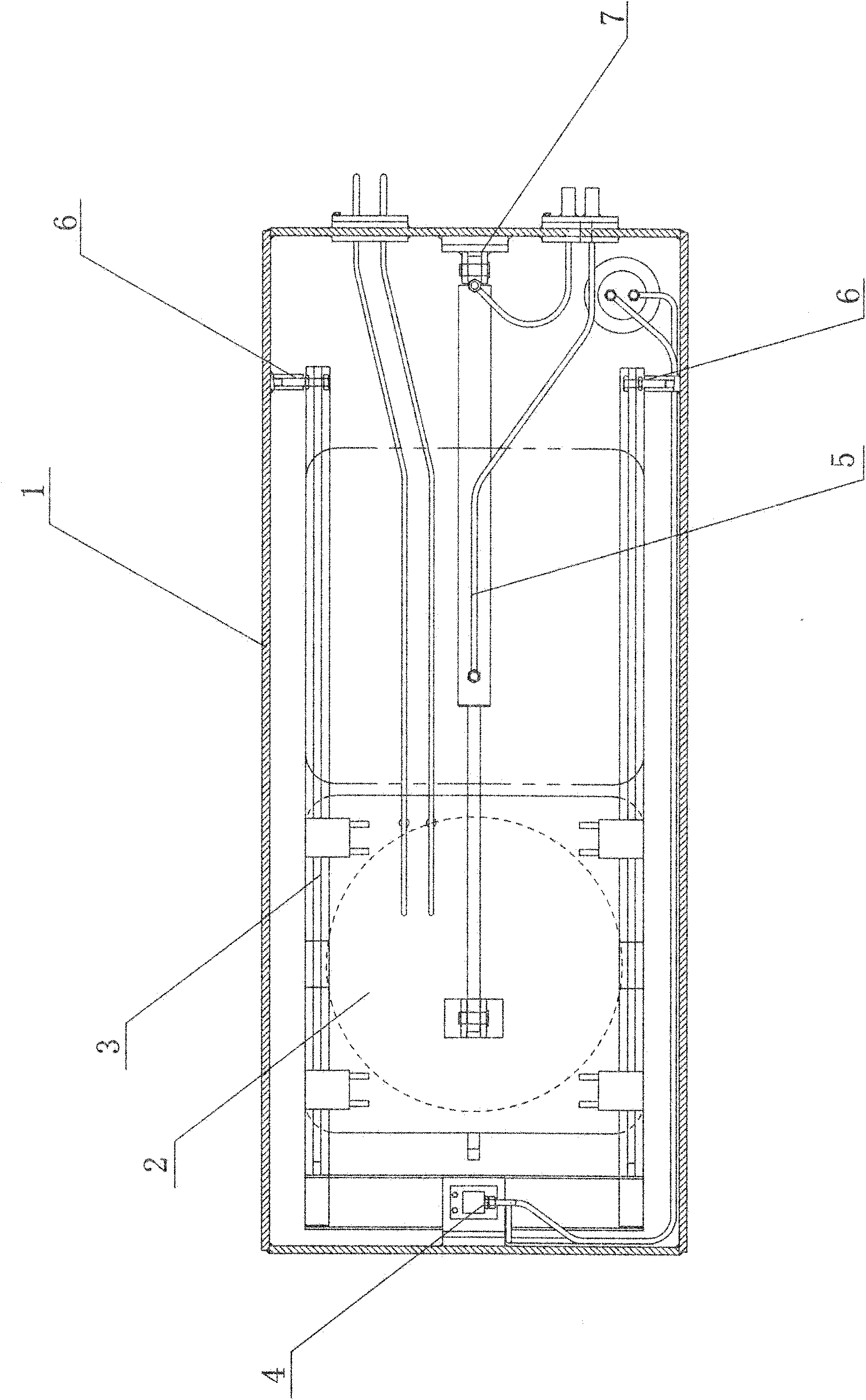

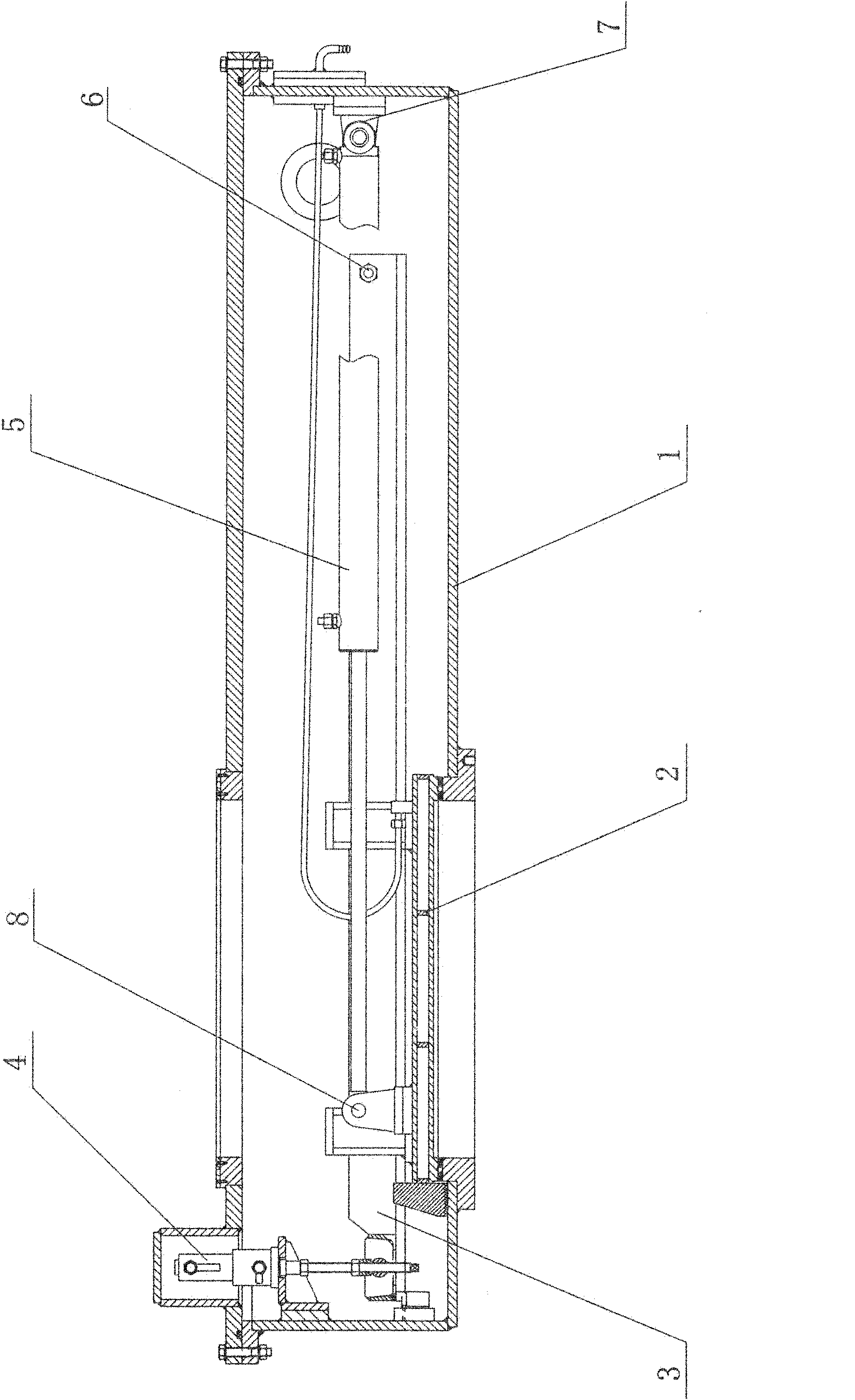

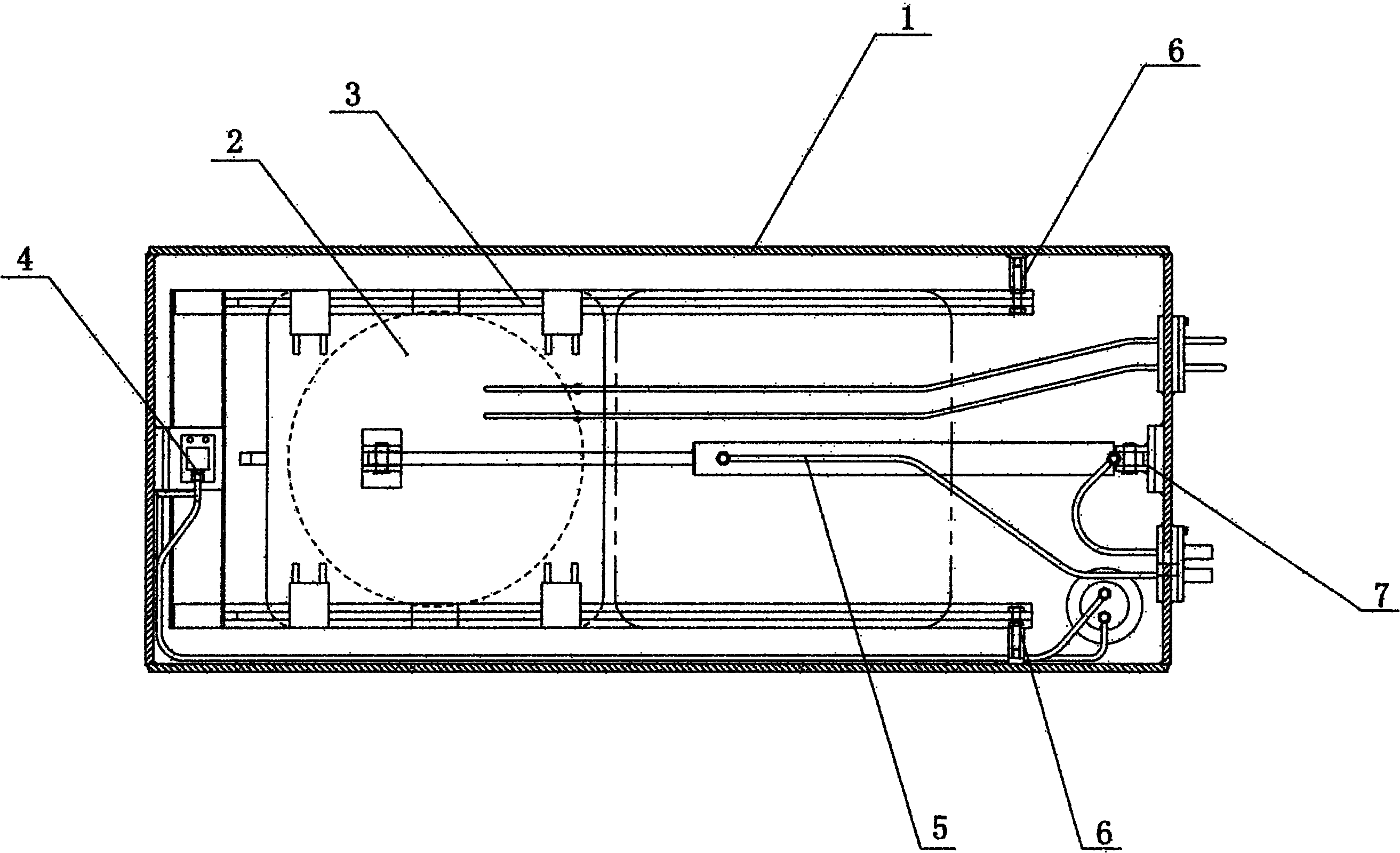

[0016] see figure 1 and figure 2 As shown, the special oil cylinder lifting isolation valve for vacuum induction furnace includes a valve body 1; a track 3, a valve plate 2, a lifting mechanism 4 and a push-pull mechanism 5 are arranged in the valve body 1; the valve plate 2 and the track 3 slidingly connected; one end of the lifting mechanism 4 is fixedly connected to the valve body 1, and the other end is axially connected to one end of the track 3; the other end of the track 3 is axially connected to the valve body 1; one end of the push-pull mechanism 5 is The hinge shaft II 8 of the push-pull mechanism is connected to the valve plate 2, and the other end is connected to the valve body 1 through the hinge shaft I 7 of the push-pull mechanism.

[0017] see figure 2 As shown, in order to simplify the structure, the lifting mechanism 4 and the push-pull mechanism 5 of the present invention respectively adopt a lifting cylinder and a push-pull cylinder in sequence. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com