Device and method for detecting airtightness of bottle cap based on sound signal processing

A technology for sound signal processing and tightness detection. It is applied in the use of liquid/vacuum for liquid tightness measurement, and by detecting the appearance of fluid at the leak point, which can solve problems such as small occupied space and achieve excellent detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

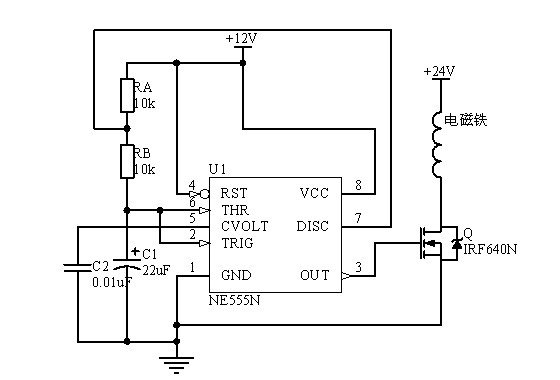

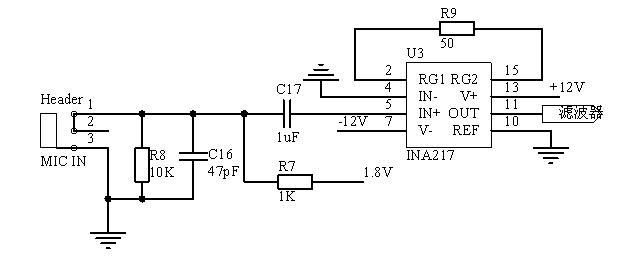

[0048] For the seal tightness detection, when the detection is started, the electromagnetic pulse impacts the surface of the bottle cap to vibrate it, and the acoustic sensor, that is, the microphone, receives the acoustic reflection signal from the bottle cap. The acoustic signal depends on the tension of the cap, which depends on the pressure inside the bottle, which depends on the tightness of the beer bottle. Based on this, we can judge whether the seal of the bottle cap is qualified by analyzing the frequency or energy of the reflected signal.

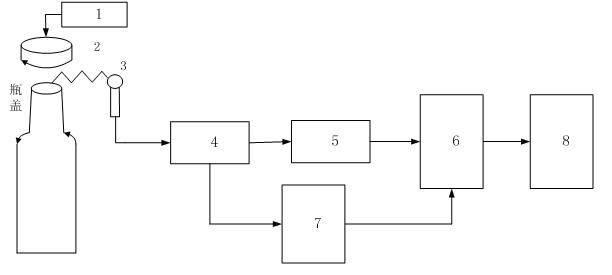

[0049] Such as figure 1As shown, the present invention includes the following components: the generation of the sound signal, the extraction of the sound signal and the analysis and processing of the sound signal. The generation of the acoustic signal is generated by the vibration of the bottle cap by the electromag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Suction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com