Intelligent material conveying device

A technology for handling devices and intelligent materials, applied in the direction of instruments, manipulators, teaching models, etc., can solve problems such as high production and maintenance costs, complex structures, and mismatched curriculum settings, and achieve the effect of improving programming ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

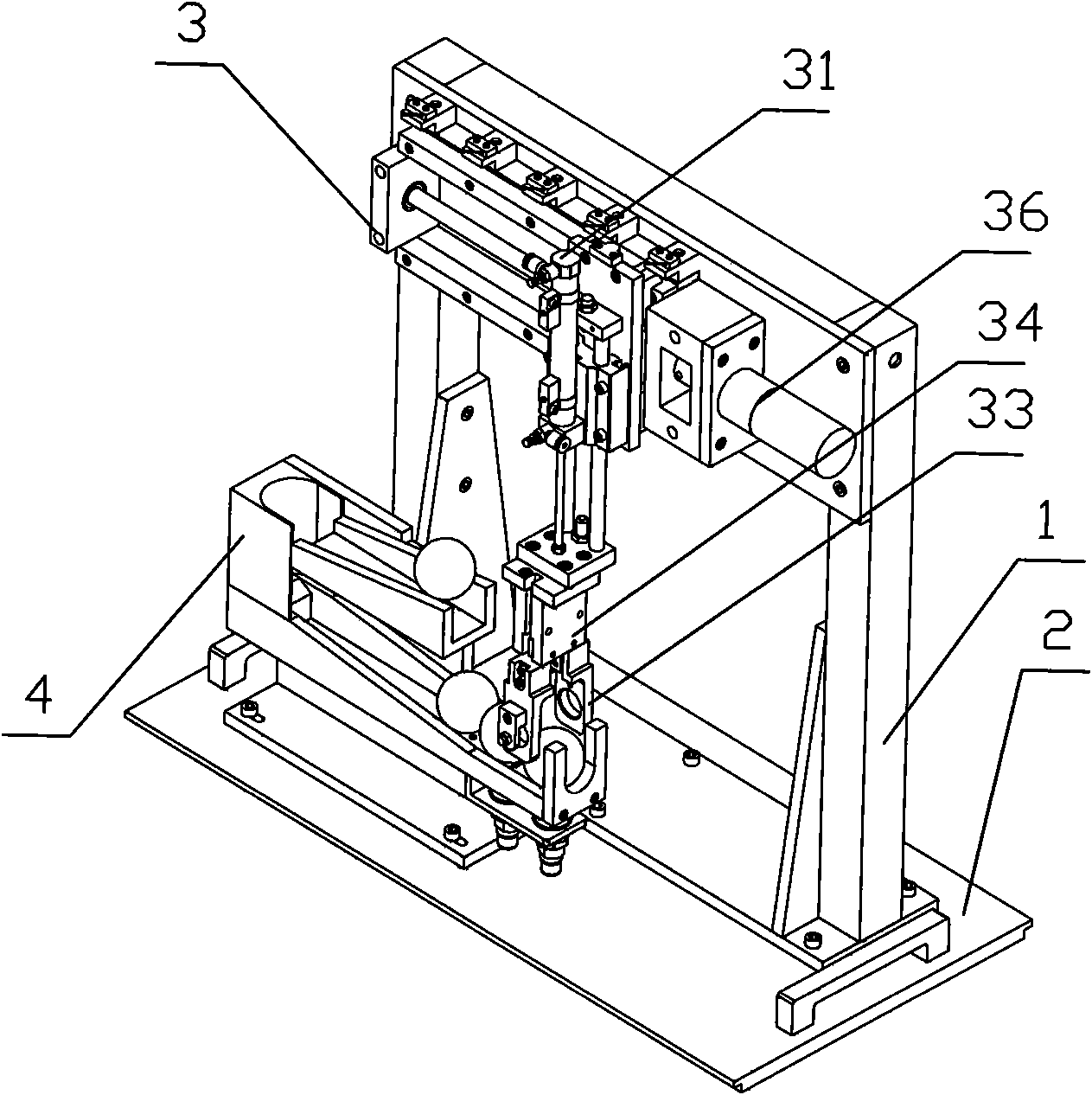

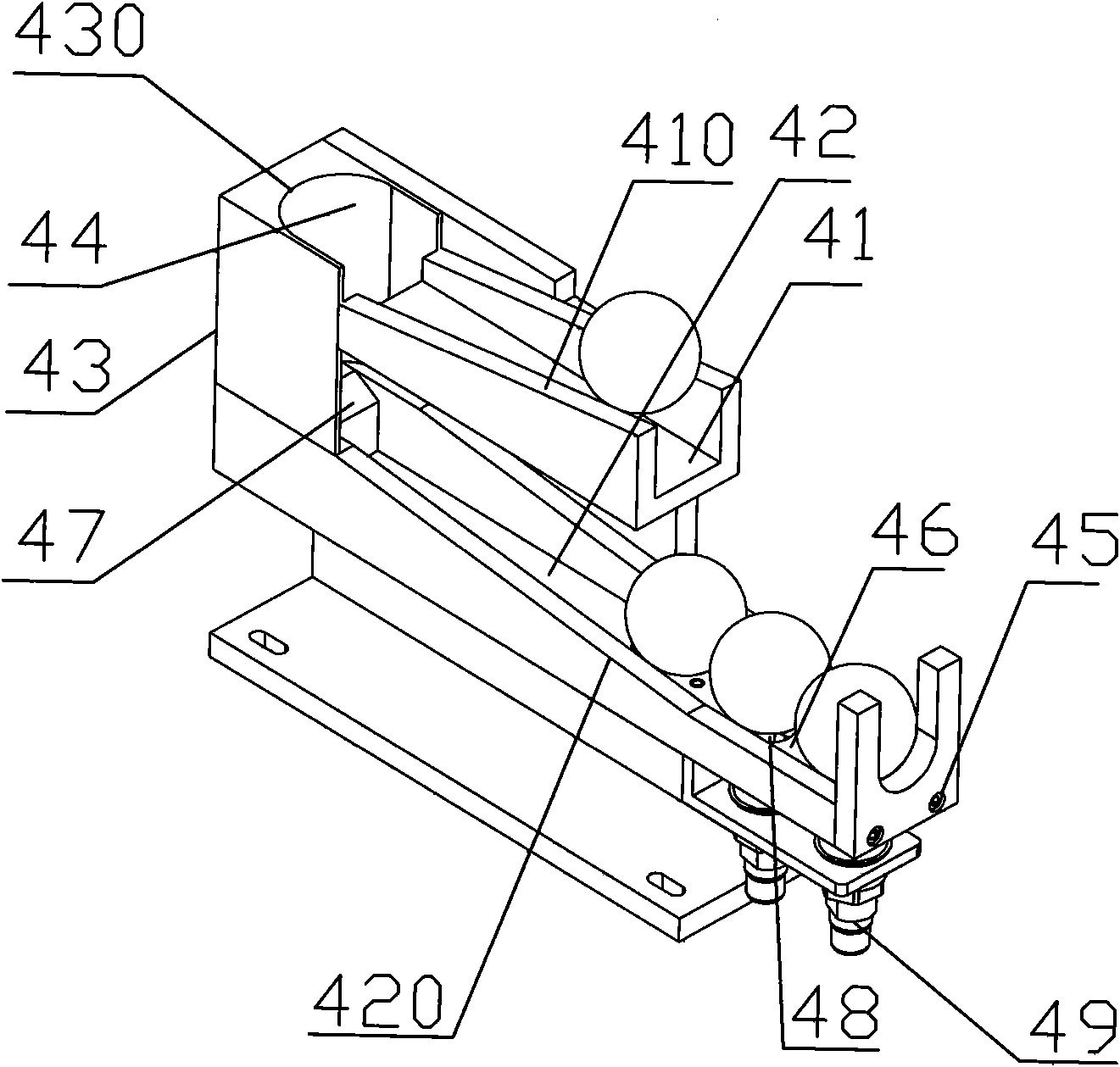

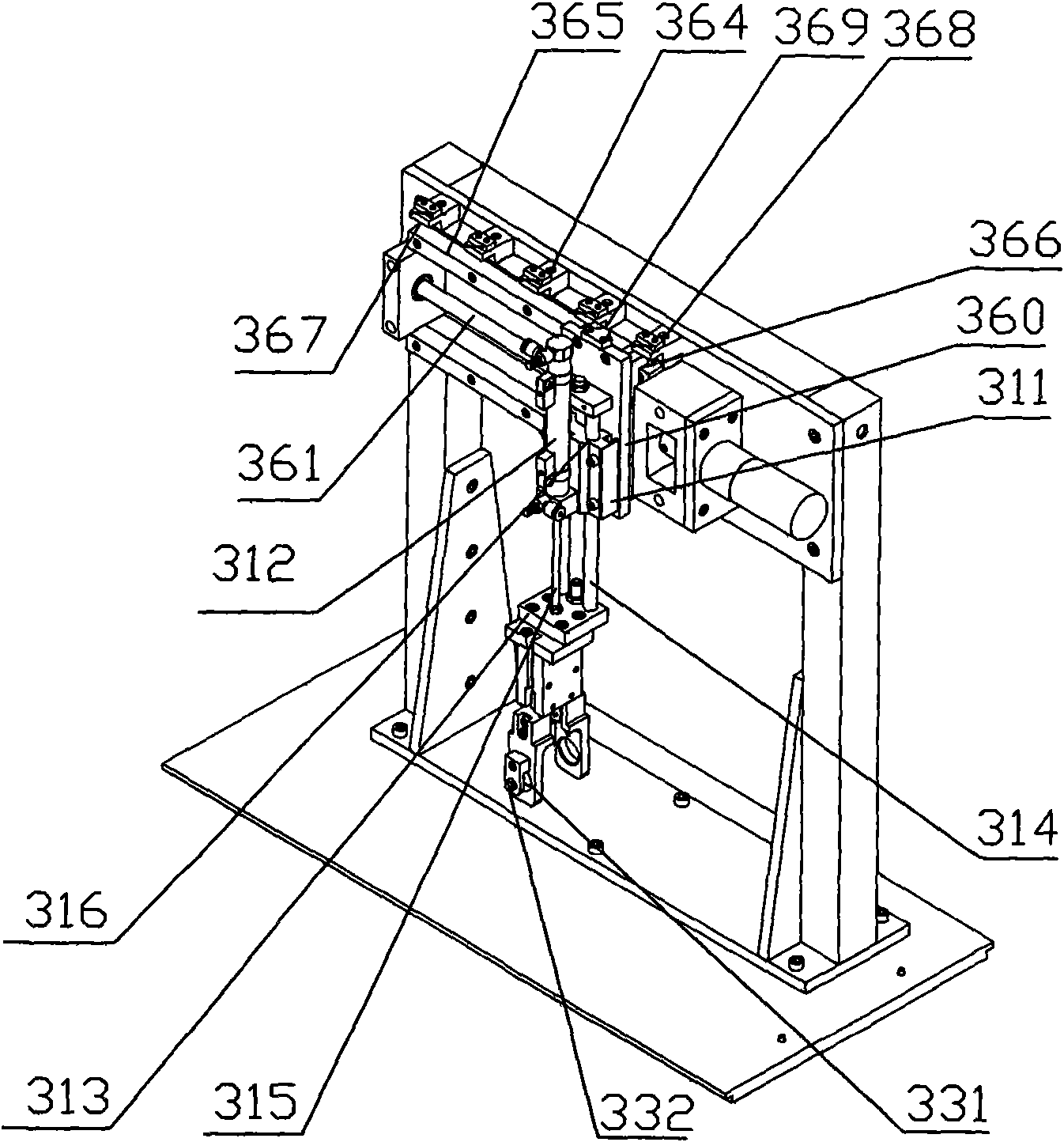

[0010] Such as figure 1 , figure 2 , image 3 As shown, an intelligent material handling device includes a support 1 and a workbench 2, and the support 1 is arranged on the workbench 2, and also includes: a biaxial linear handling device 3, a feeding device 4, and a control unit. The biaxial linear conveying device 3 is arranged on the support 1, and the biaxial linear conveying device 3 is fixed on the support, which ensures that the biaxial linear conveying device 3 can move smoothly. The two-axis linear conveying device 3 includes a manipulator claw 33, a ball screw device 36 providing a horizontal degree of freedom for the manipulator claw 33, a guide rod cylinder device 31 providing a vertical degree of freedom for the manipulator claw 33, and the ball screw device 36. A slider 360 driven by a ball screw pair 361 is provided. The guide rod cylinder device 31 includes a cylinder 312 and a connecting plate 313. The cylinder 312 is fixedly connected to the slider 360, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com