500kv large-span support type tubular bus

A pipe busbar and supporting technology, which is applied in the direction of semi-enclosed busbar devices, can solve the problems of large deflection of large-span supported pipe busbars, and achieve the effects of strong radio interference capability, reduced overall deflection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

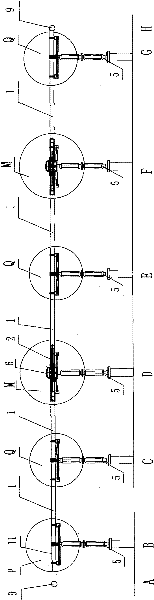

[0033] The 500 kV support tube busbar is a kind of busbar under the voltage level of 500 kV, such as figure 1 The confluence busbar shown is only one phase, and the busbar is composed of three phases A, B, and C. The three phases are generally exactly the same, arranged side by side and horizontally, and the distance is generally 6-7m. The length of the supporting tube mother is different, and it is generally expressed by the number of spans and the span. in figure 1 The one shown is 5 spans with a span of 28 meters. In practical applications, the busbar may generally have 4 to 10 spans.

[0034] Usually, when calculating the deflection of pipe parent, the calculation formulas for distributed and concentrated loads are as follows:

[0035]

[0036]

[0037] Among them, A 1 、A 2 is the internal force coefficient of the continuous beam, E is the modulus of elasticity, J is the moment of inertia, L js is the effective span of pipe mother, q 分布 = S 截面 ×ρ 线密度 .

[00...

Embodiment 2

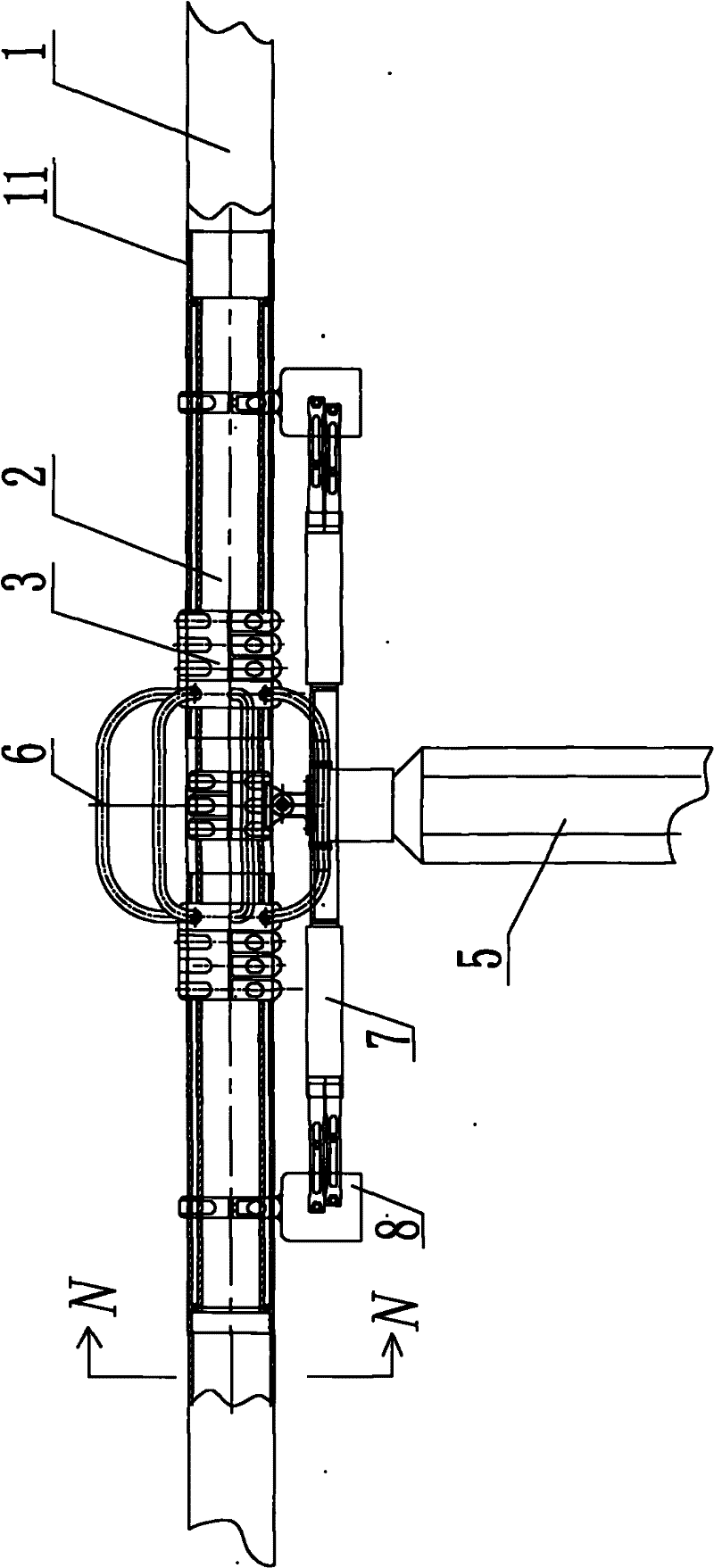

[0061] The difference between this embodiment and Embodiment 1 is that, on the basis of Embodiment 1, this embodiment adds a pipe mother telescopic fitting 6, and the above pipe mother telescopic fitting 6 is set at the expansion and contraction position of the pipe bus 1 due to the expansion and contraction of the temperature difference. The two tube mothers are electrically connected to pass current.

[0062] like figure 2 , Image 6 As shown, the above-mentioned duct bus telescopic fitting 6 is arranged between two sections of bus bars 1, and it is composed of at least six soft wires, which are evenly distributed in a lantern shape, and the number of soft wires can be set according to actual needs, namely It can be six, eight, ten or even more. Specifically, eight flexible conductors are arranged between the two sections of pipe busbar 1, and the eight flexible conductors are evenly distributed in a lantern shape, as shown in Image 6 As shown, the angle between the two...

Embodiment 3

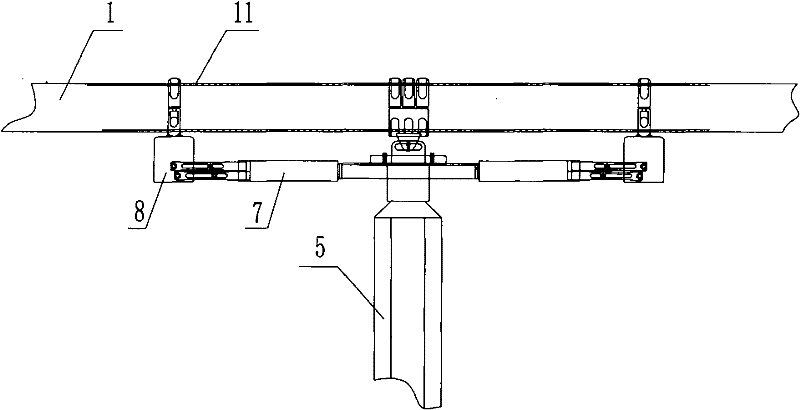

[0066] The difference between this embodiment and the above-mentioned embodiments is that, on the basis of Embodiments 1 and 2, this embodiment also adds a bracket type damper, and when the pipe bus 1 vibrates, frictional damping is generated to eliminate the breeze vibration of the pipe bus , while effectively reducing breeze vibrations. In addition, the bracket type vibration absorber is mainly supported by the post insulator 5, which is different from other vibration absorbers by the pipe mother, so the deflection of the pipe mother can be reduced.

[0067] like figure 2 As shown, in this embodiment, the bracket type damper includes a damper body 7 , the two ends of the damper body 7 are connected with friction plates 8 , and the friction plates 8 are connected with the pipe bus 1 . Among them, the two ends of the damper body 7 are provided with clamps. When the pipe bus 1 vibrates up and down, the "claws" at both ends of the damper body 7 grab the friction plate 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com