High-strength hot-dip-galvanized steel sheet having excellent moldability, and method for production thereof

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip coating process, chemical instruments and methods, etc., can solve the problems of reduced formability, stretchability, hole expandability and bendability, etc., to achieve Ensures safety, hole expandability, and excellent bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

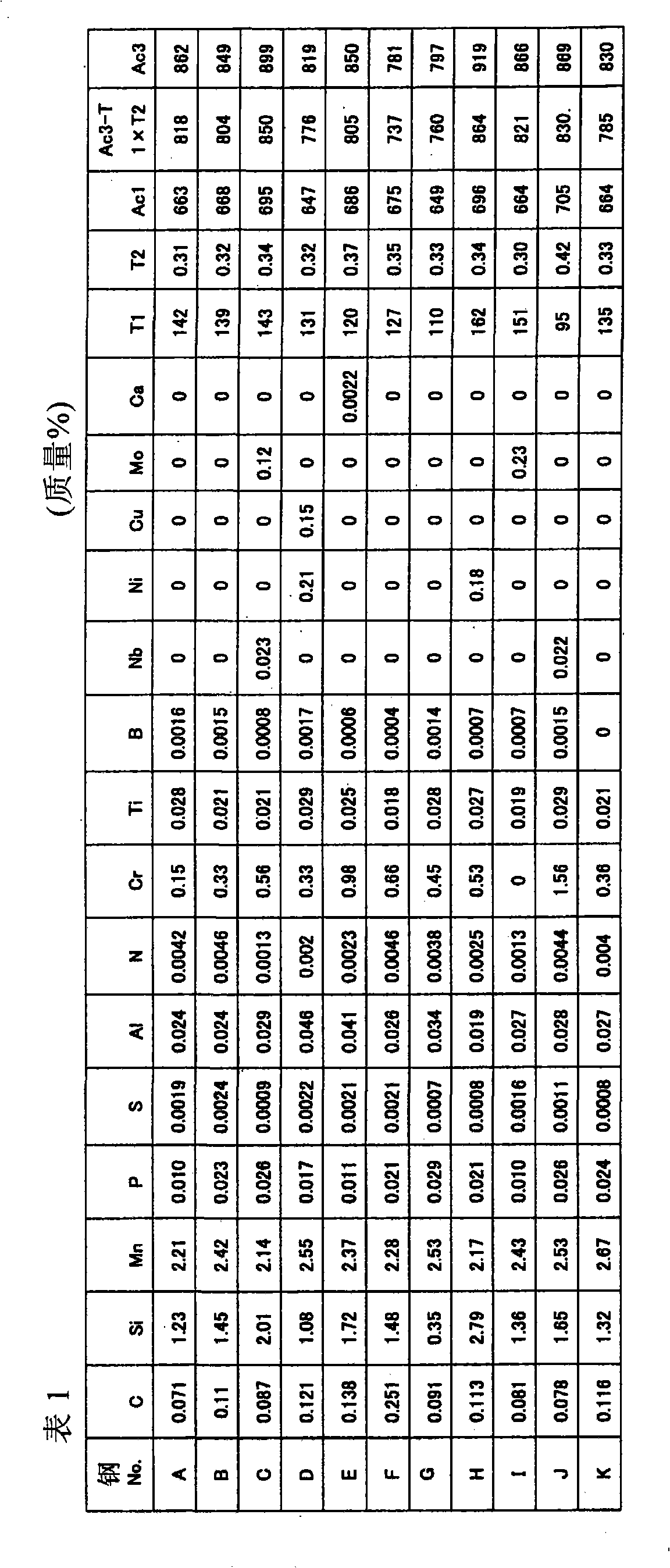

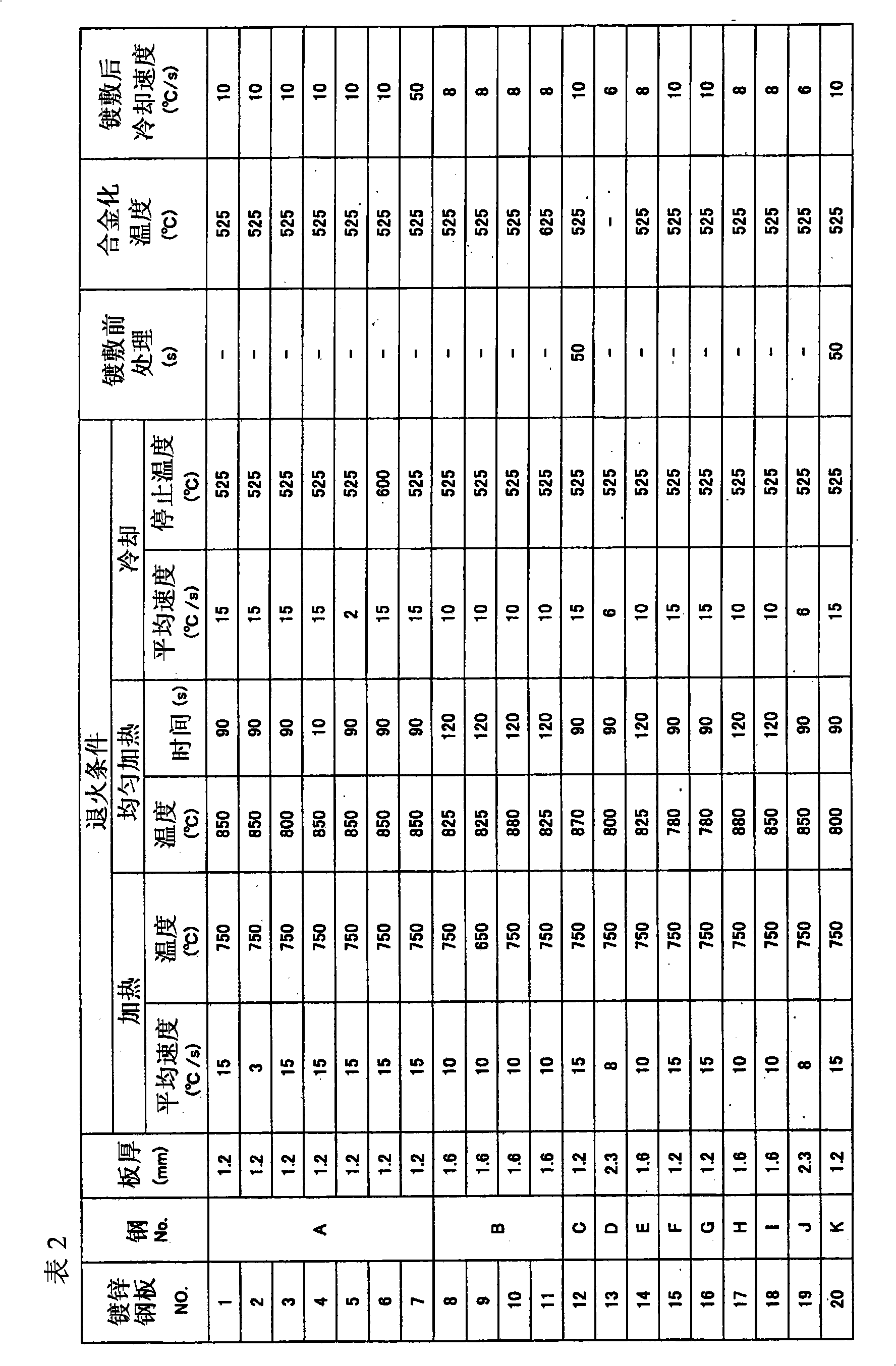

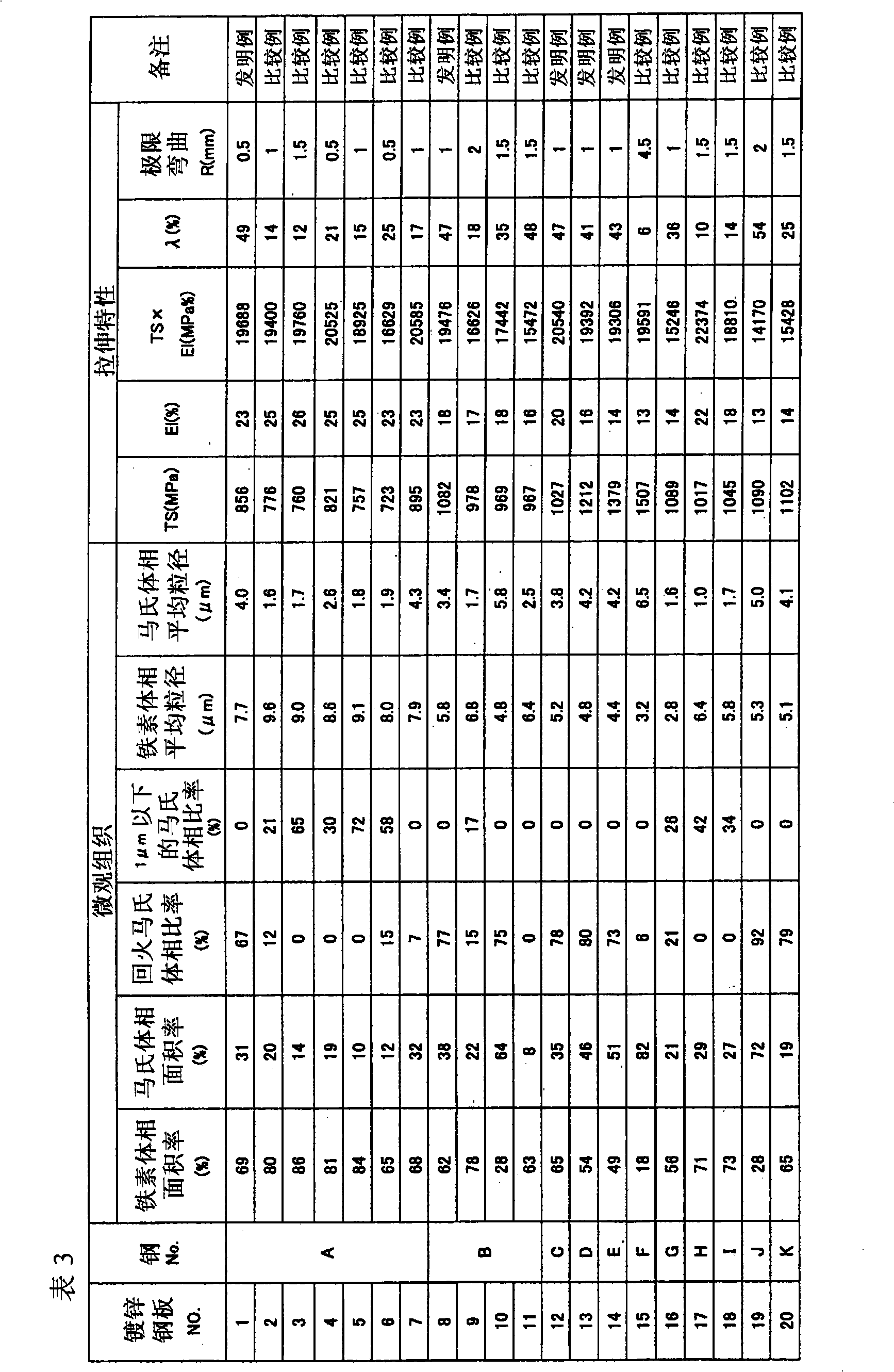

[0104] Steel Nos. A to K having the composition shown in Table 1 were melted in a converter and cast into slabs by continuous casting. After heating the obtained steel slab to 1200 degreeC, it hot-rolled at the finishing temperature of 850-920 degreeC, and coiled at the coiling temperature of 600 degreeC. Next, after pickling, it was cold-rolled at a rolling reduction of 50% to the plate thickness shown in Table 2, and annealed under the annealing conditions shown in Table 2 using a continuous hot-dip galvanizing line. Perform heat treatment before plating for the time shown in Table 2, and then immerse in a 475°C galvanizing bath containing 0.13% Al for 3 seconds to form a coating with a coating weight of 45g / m 2 The galvanized layer was alloyed at the temperature shown in Table 2 to produce hot-dip galvanized steel sheets No. 1 to 20.

[0105] In addition, as shown in Table 2, some galvanized steel sheets were not subjected to pre-plating heat treatment and alloying treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com