Extended pile with a point plate formed the critical inner-hole

A technology of enlarging discs and enlarging head piles, which is applied in the field of enlarging head piles, and can solve problems such as not proposing inner holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

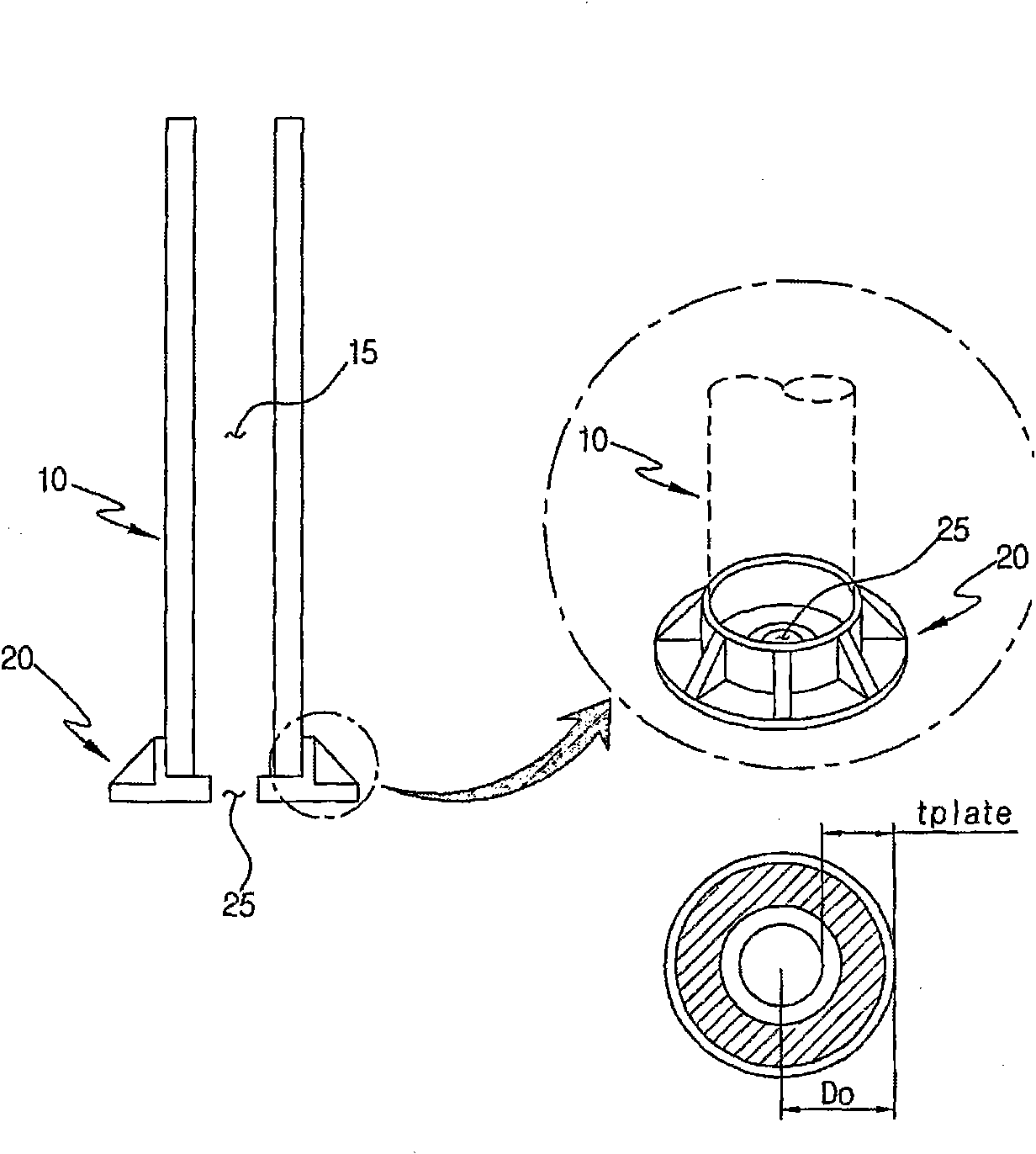

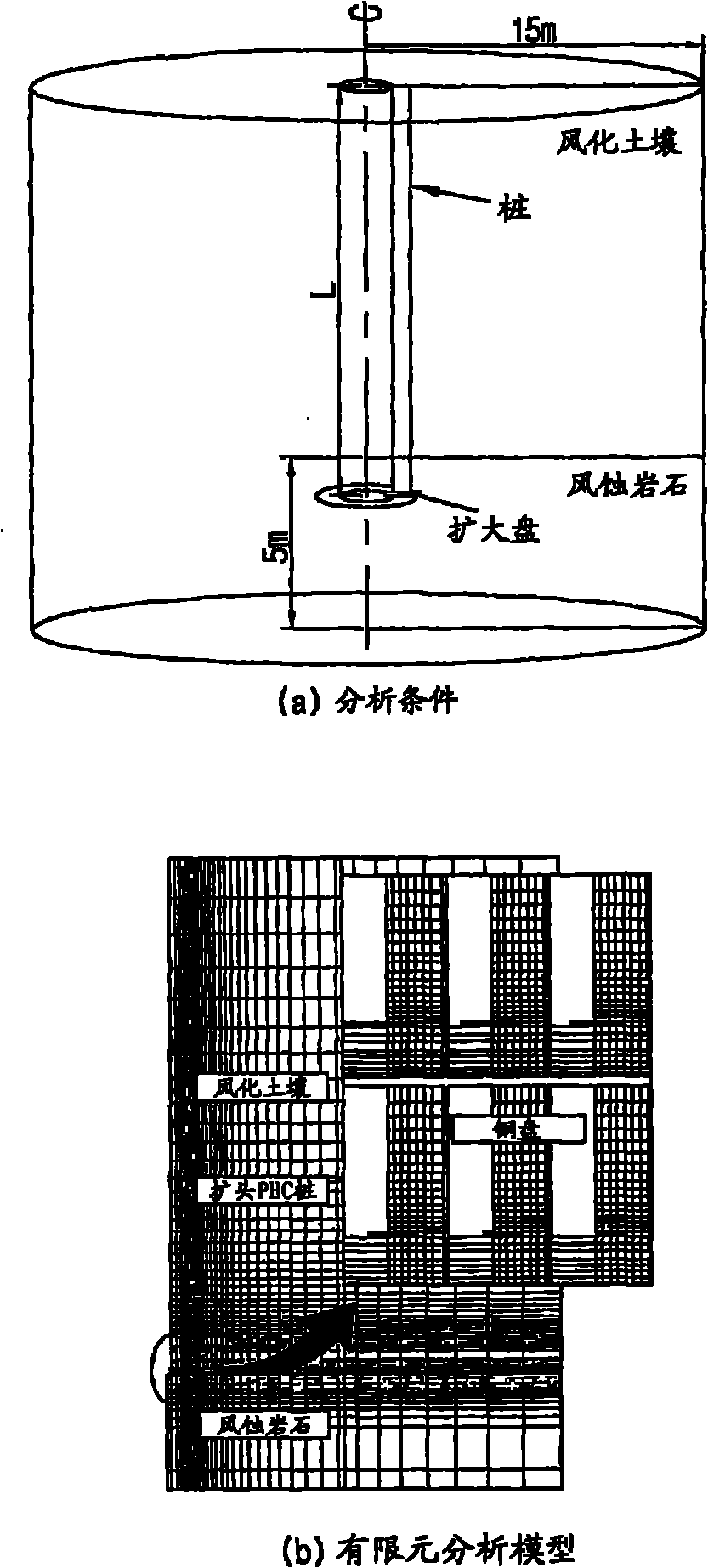

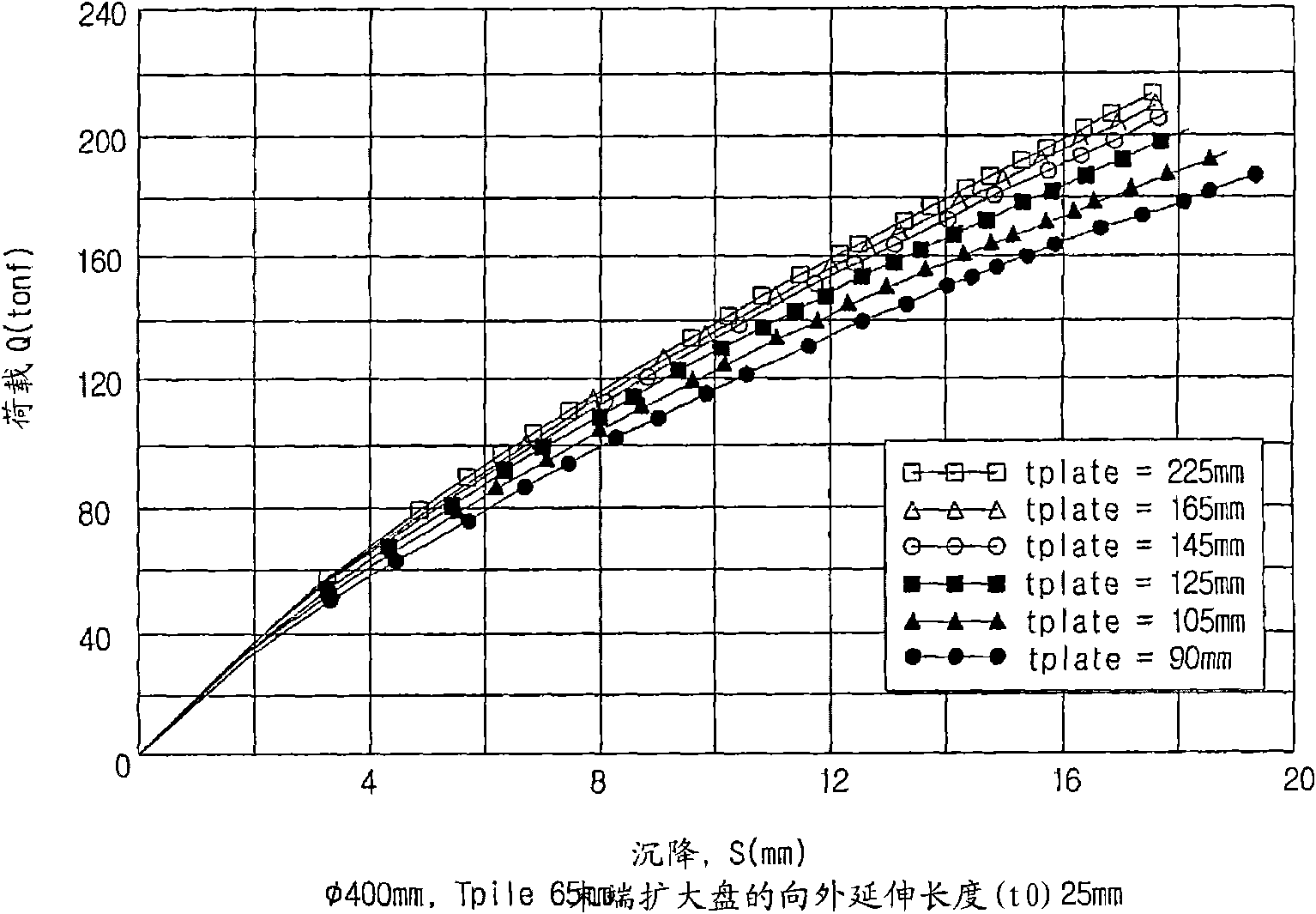

[0016] In order to realize the above-mentioned technical solution, the present invention provides a head-enlarging pile, which includes an enlarged end disc, which is arranged at the end of the hollow circular pile for increasing the end of the hollow circular pile. Supporting force, the outer diameter of the end enlarged disk is larger than the outer diameter of the end cross-section of the hollow circular pile, wherein the end enlarged disk is in the form of an annular band with an inner hole pierced in its cross section, so The diameter of the inner hole is smaller than the diameter of the central cavity of the hollow circular pile, and the width of the end enlarged disk is in the range of 40% to 70% relative to the outer diameter of the end enlarged disk.

[0017] The headed piles may be pretensioned prestressed high strength concrete (PHC) piles.

[0018] An exemplary embodiment of the present invention will be described in detail below with reference to the accompanying ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap