Heat exchanger comprising a fractal pipe structure

A heat exchanger and tube structure technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger tubes, etc., can solve problems such as distribution and non-uniform heat exchange power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

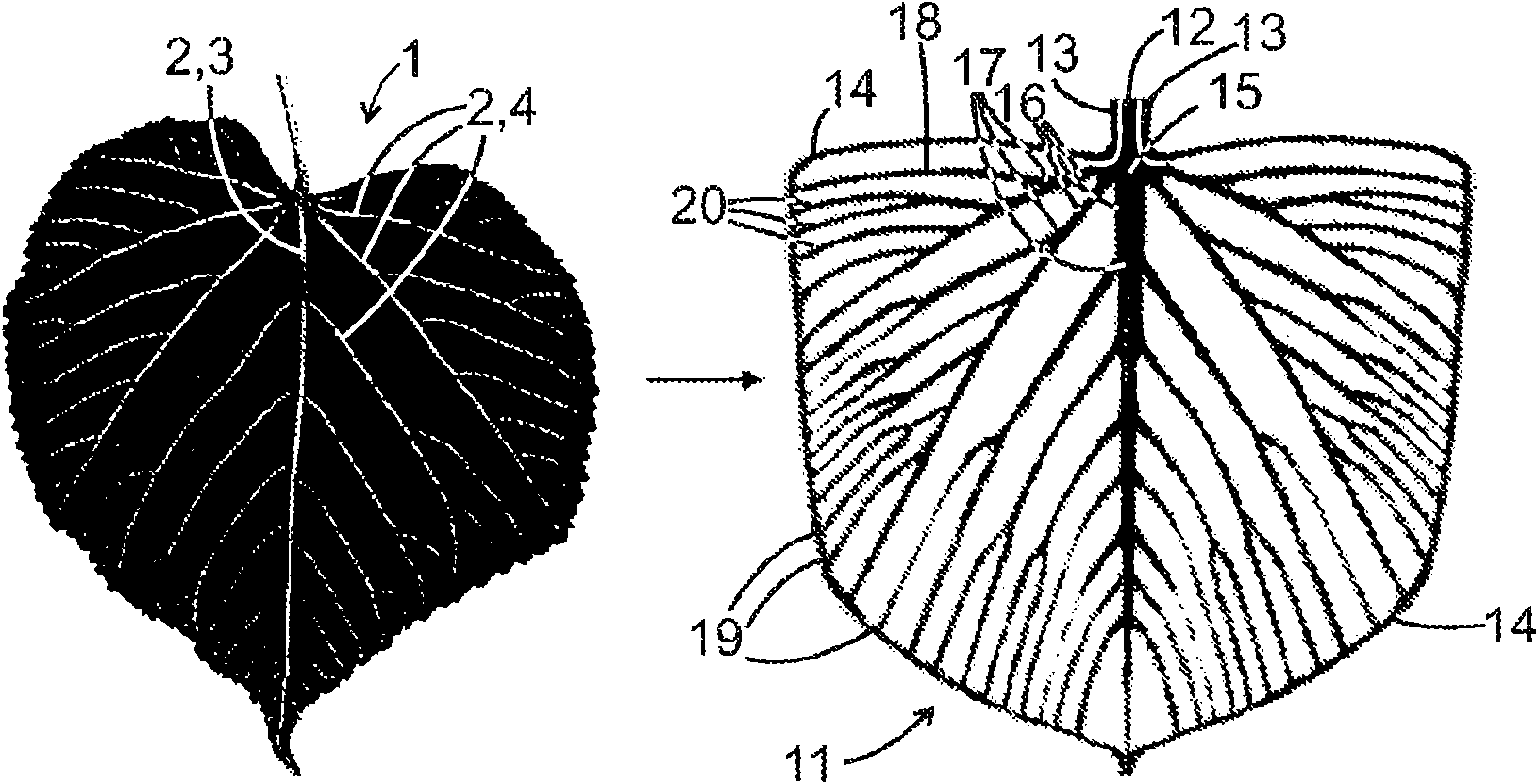

[0019] exist figure 1 In the plant leaf 1 shown, the problem of distributing the water supplied via the petiole to all the cells of the leaf through the network of veins 2 with minimal energy utilization has been solved over millions of years of evolution. The system of veins 2 comprises a main shaft 3 , which continues in a straight line from the petiole, from which cotyledonary veins 4 distributed over the length of the main shaft or at the root of the main shaft form.

[0020] As the distance from the main axis 3 increases, the cotyledon veins 4 branch off one or more times.

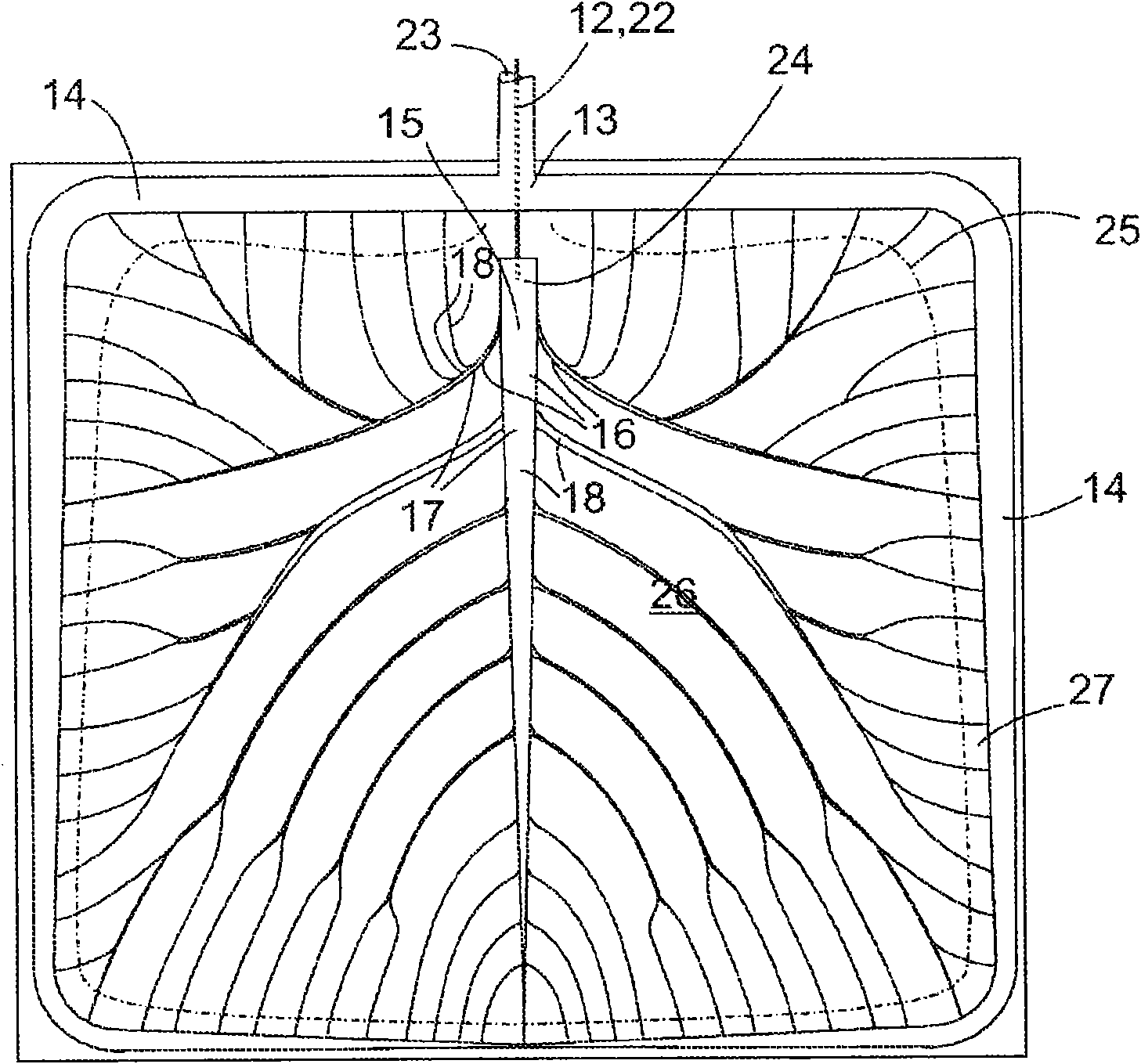

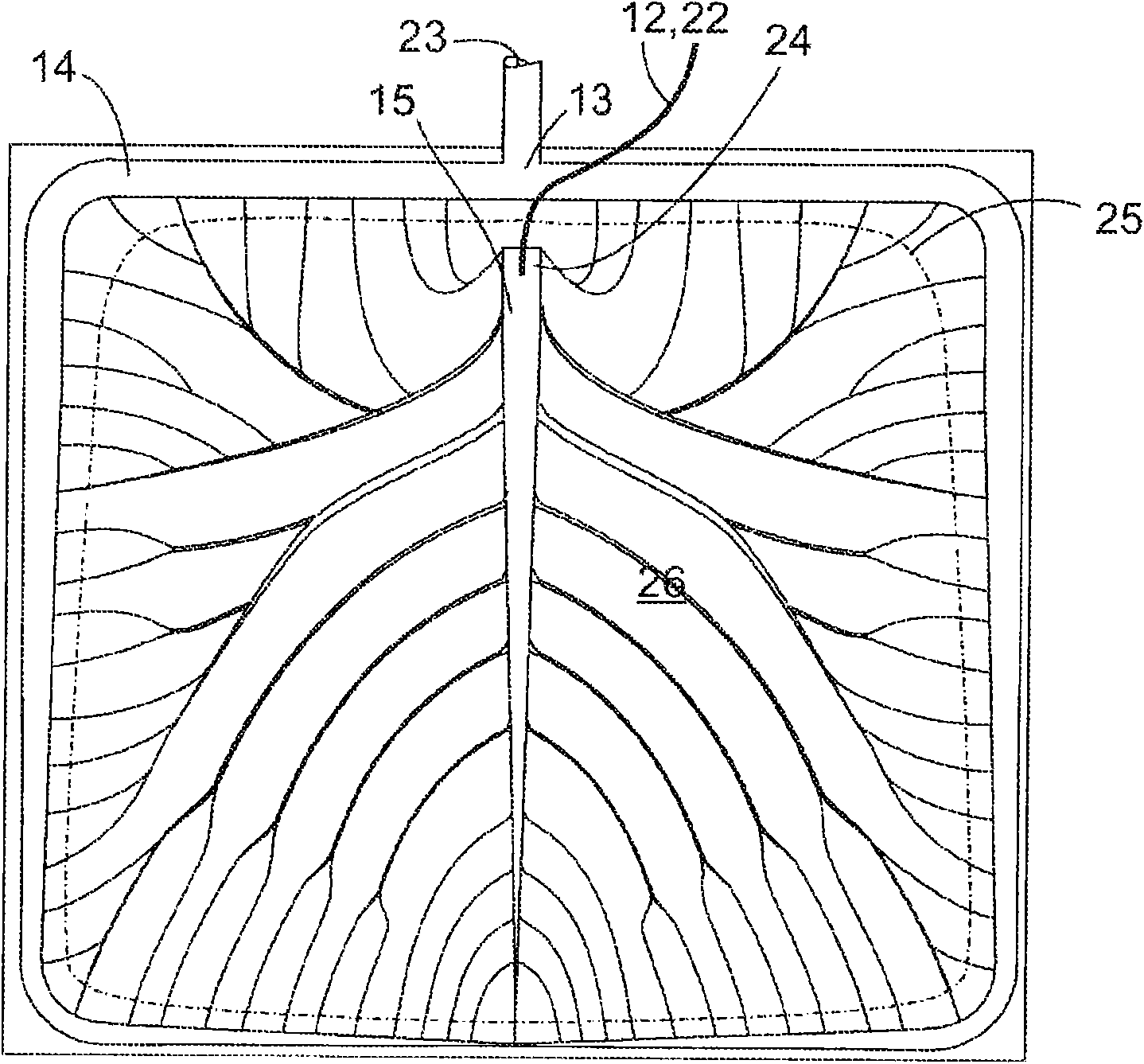

[0021] figure 1 The heat exchanger 11 schematically shown in the figure adopts the bifurcated tube structure of the plant leaf 1, but the fundamental difference from the plant leaf 1 is that the heat transfer fluid supplied at the input connection 12 cannot be like the water supplied to the leaf 1 That evaporates and has to be sent away again via the output connection 13 . However, the flow-promoti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com