Seedling-raising disk soil compacting method

A seedling tray and soil technology, which is applied in the direction of compactors, applications, agricultural machinery and tools, etc., can solve the problems of insufficient compaction of the subsoil, more labor, and time-consuming, so as to improve operation efficiency, ensure basic seedling requirements, and reduce Nomoto's effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

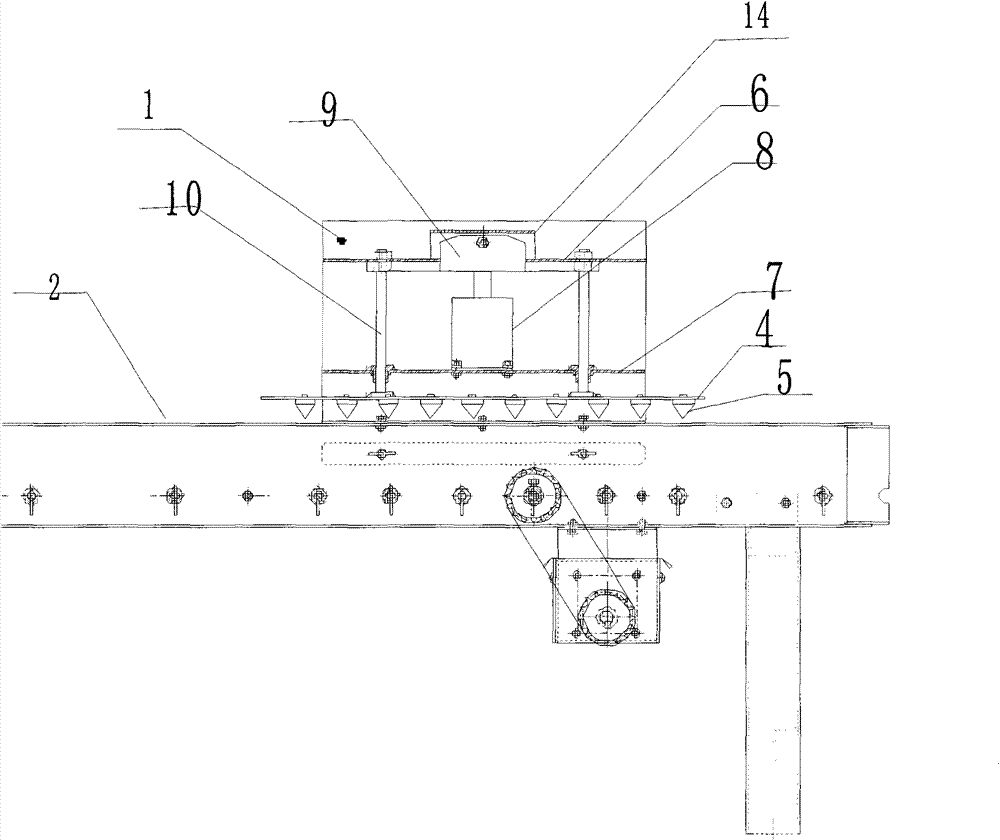

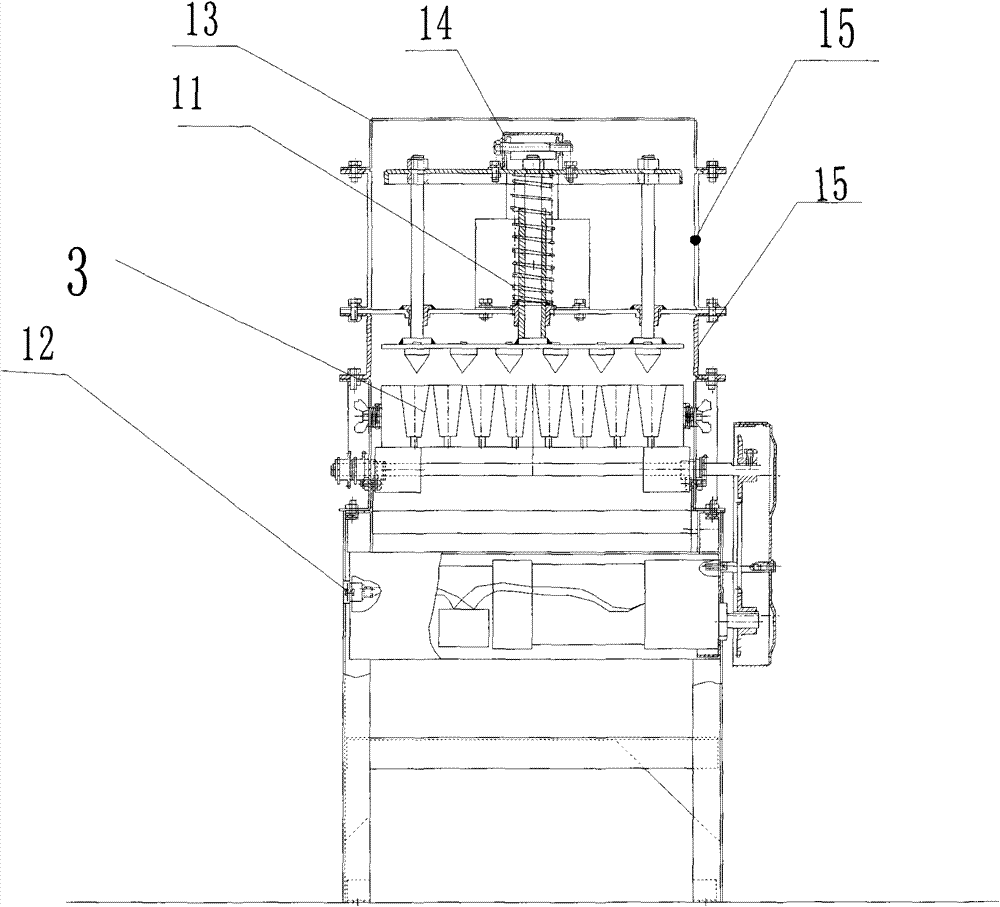

[0019] As shown in the figure, it includes: compacting device 1, seedling tray assembly line guide rail 2, seedling tray 3, compacting plate 4, pressure head 5, upper fixing plate 6, lower fixing plate 7, electromagnet 8, armature 9, guide Column 10, return spring 11, photoelectric switch 12, cover plate 13, armature connection block 14, support frame 15.

[0020] The compacting device 1 is arranged on the frame crossbeam of the seedling raising line, that is, on the seedling raising line guide rail 2 . The seedling raising tray 3 moves forward on the walking track of the guide rail, and passes through each process successively. A photoelectric switch 12 is arranged on the beam directly below the compacting device 1 .

[0021] The compacting device 1 is mainly composed of a compacting plate 4, several indenters 5, six guide posts 10, a support frame 15, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com