Punching machine for sandwich plate

A punching machine and sandwich panel technology, applied in metal processing and other directions, can solve the problems of difficult punching positioning, slow work efficiency, etc., and achieve the effects of simple operation, improved accuracy and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

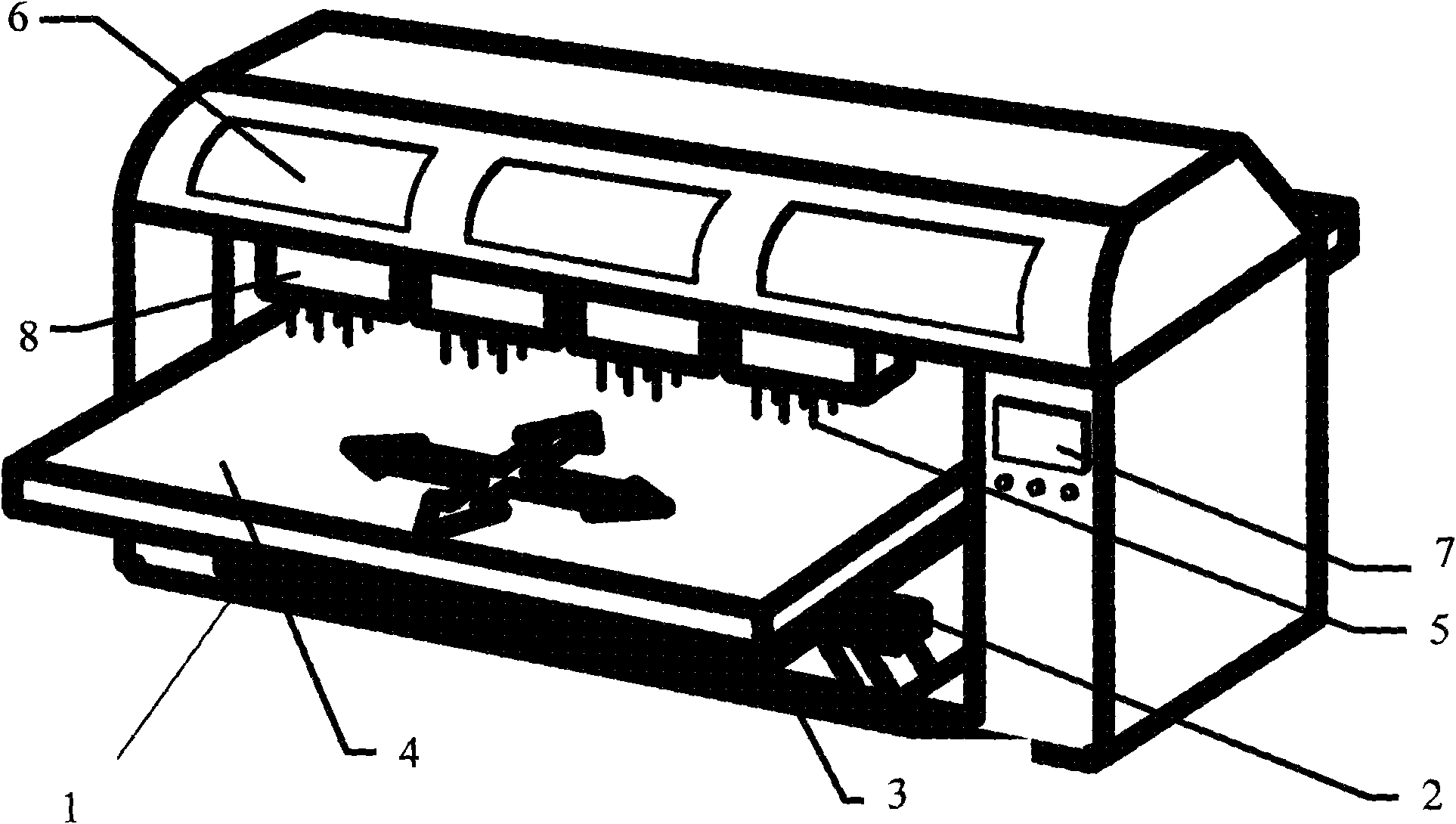

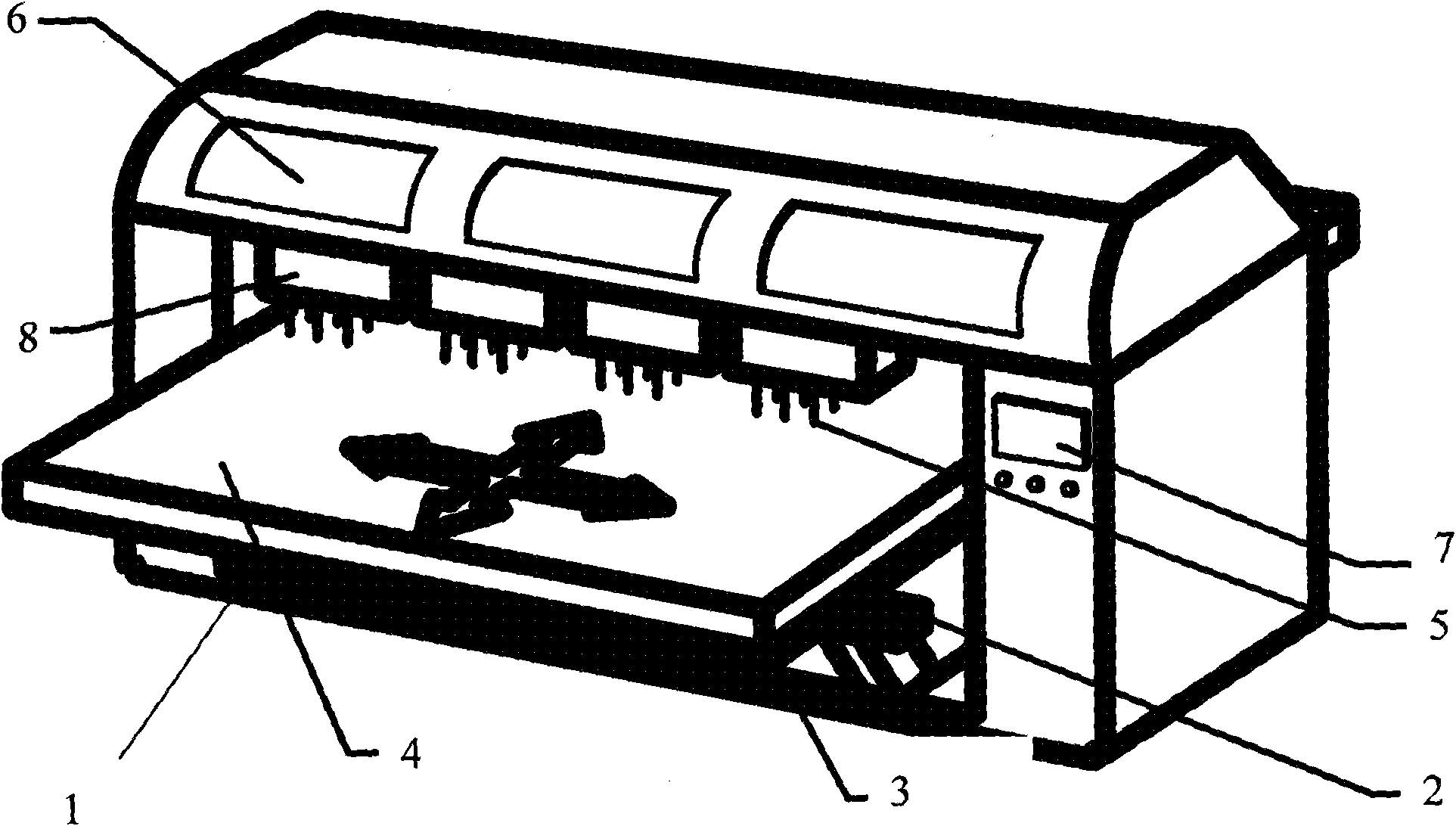

[0013] figure 1 It is a structural representation of a specific embodiment of the present invention, combined below figure 1 The embodiments of the present invention are introduced.

[0014] Such as figure 1 As shown, the punching machine for sandwich panels provided by the embodiment of the present invention includes a frame (1), on which a transverse track (2) and a longitudinal track (3) are installed, and the transverse track ( 2) and the longitudinal rail (3) are equipped with a four-way workbench (4), and a drill bit group (5) is arranged above the four-way workbench (4), and the drill bit group (5) is installed on the power group (8) On the top of the above-mentioned drill bit group (5), an observation window (6) is provided, and a numerical control device (7) is also provided on the above-mentioned frame (1).

[0015] The punching machine for sandwich panels provided by the present invention adopts a drill set (a plurality of drill bits can be installed on the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com