Airbag wiper in automobile cleaning equipment

A technology for cleaning equipment and airbags, applied in the direction of vehicle external cleaning devices, etc., can solve the problems of car loss, increased cleaning costs, and insufficient operating space, and achieve the effect of improving decontamination efficiency and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

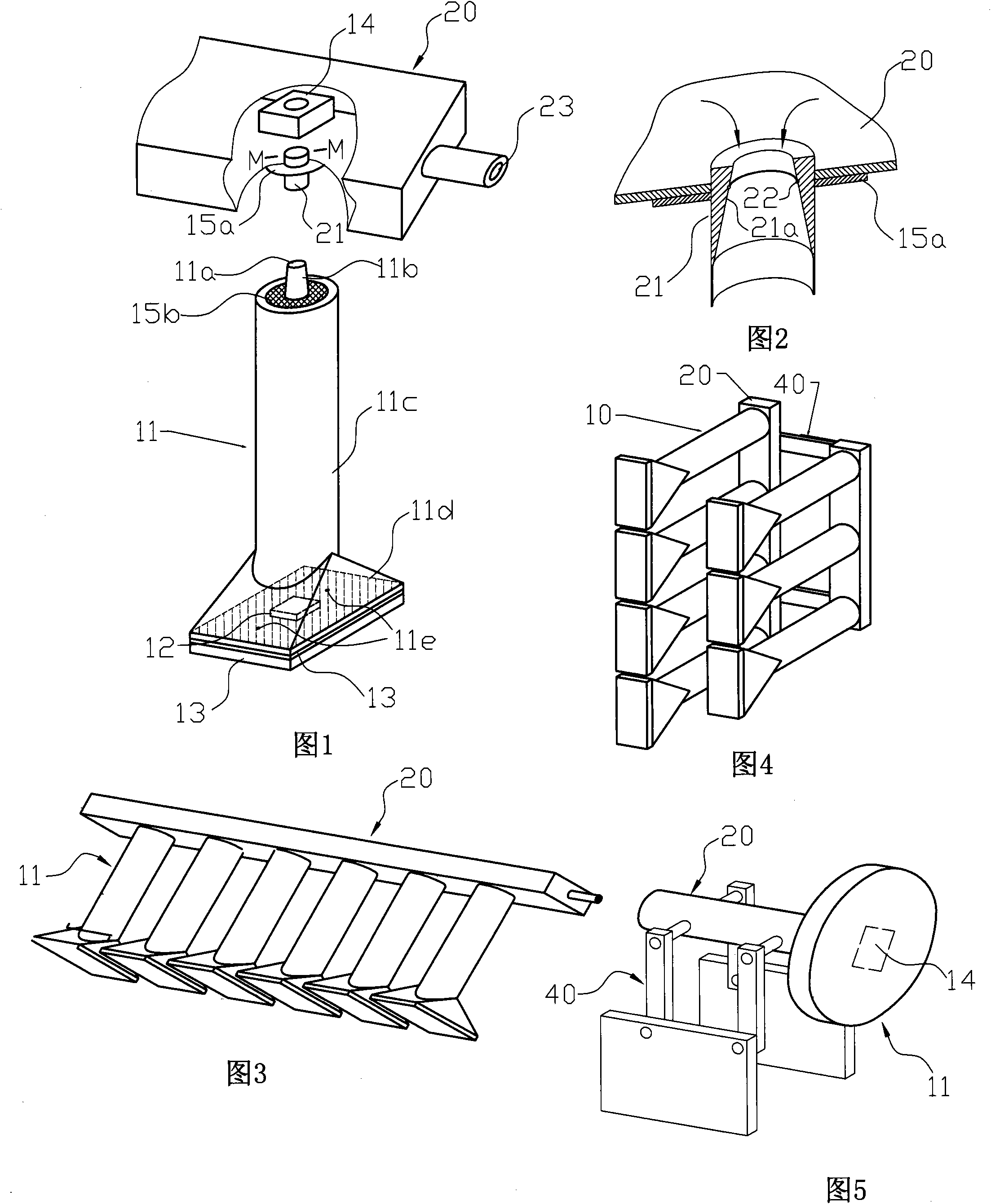

[0025] control figure 1 The airbag wiper 10 mainly consists of an airbag 11, a pneumatic vibrator 12 and a wiping material 13, and the airbag wiper 10 is connected to a square trachea 20 with high-pressure gas. The air bag is a combination of a cylindrical air bag 11c and a quadrangular pyramidal air bag 11d. The air pipe 20 is provided with a corresponding air outlet pipe 21 , and the air inlet of the air outlet pipe 21 is connected with a solenoid valve 14 to control the gas entering the airbag wiper 10 . The inner peripheral surface of the air outlet pipe 21 is provided with an inner conical surface 21a with the same taper as the upper outer conical surface of the inlet pipe 11a. The inner conical surface 21a is also provided with a sealing ring groove, and a sealing ring 22 is placed in the groove. The airbag wiper 10 is plugged in the air outlet pipe 21 of the trachea 20 through the air inlet pipe 11a on it to realize the communication between the two, and utilize the mu...

Embodiment 2

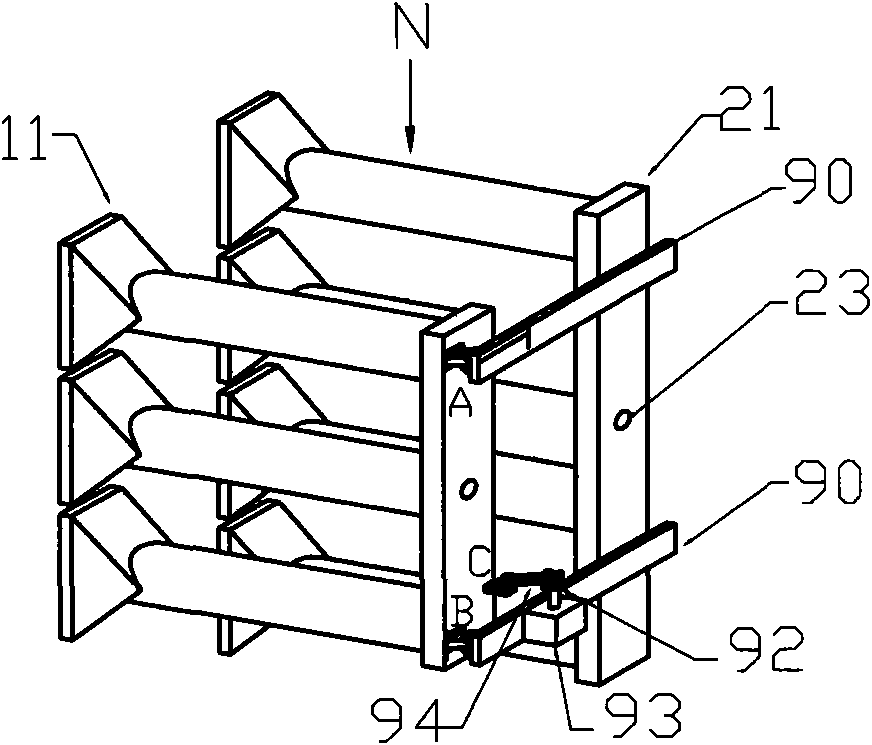

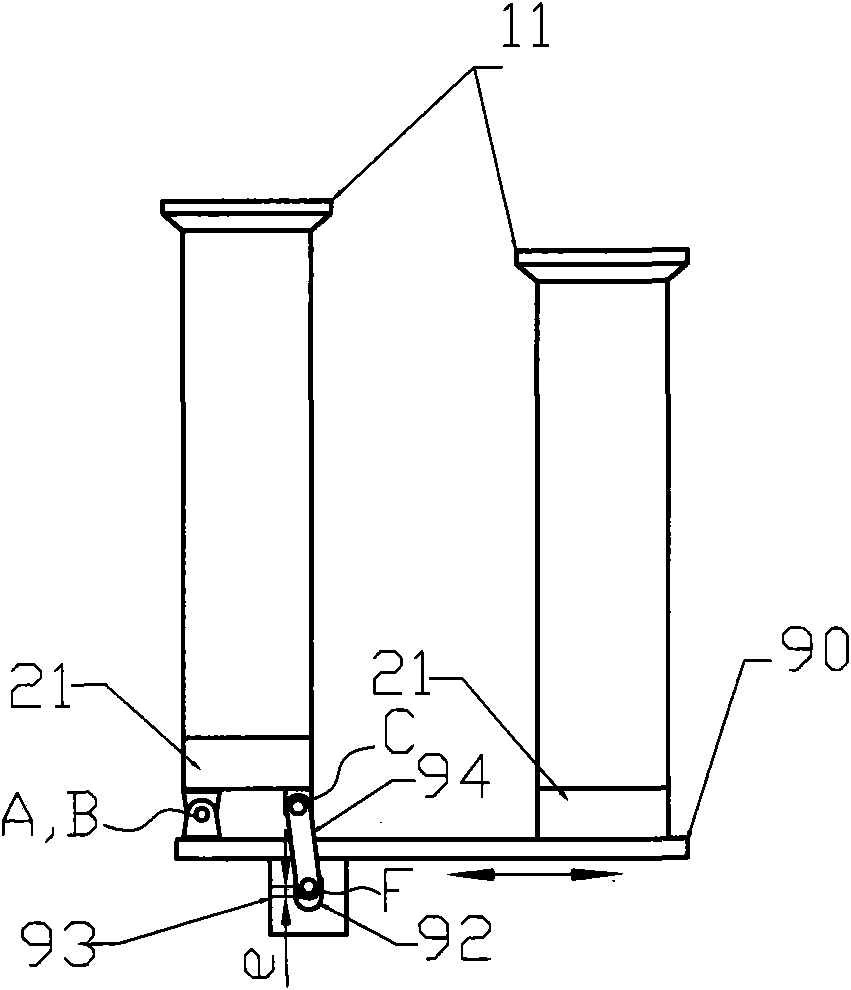

[0032] The wiping movement of the airbag to the car body can also be produced by the swing mechanism, such as Image 6 . Pneumatic vibrators are not placed in the airbag 11 like this. The airbag wiper is mainly composed of a trachea, an airbag, a wiping material, a rotating cylinder, a bracket, a connecting rod and an eccentric block. Wherein the rotary cylinder 93 is installed on the support 90, the communication form of the air pipe 20 and the air bag 11 and the structural form of the air bag 11 are the same as the above-mentioned embodiment, and the required swing of the air bag to wipe the vehicle body is composed of the air pipe 20, the rotary air cylinder 93, the support. 90, the connecting rod swing mechanism that connecting rod 94 and eccentric block 92 form. The bracket 90 is fixed on the car cleaning equipment, two points A and B at a certain distance on the trachea 21 are respectively hinged with the bracket 90, and the point C on the trachea 20 which is not in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com