Electroplating cathode conductive device

A cathode conductive and pressing device technology, applied in the direction of the electrode, etc., can solve the problems of poor contact between the rotating shaft and the brush, affect the quality of the plate roller, and uneven coating, so as to avoid poor contact, ensure service life, and uniform coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

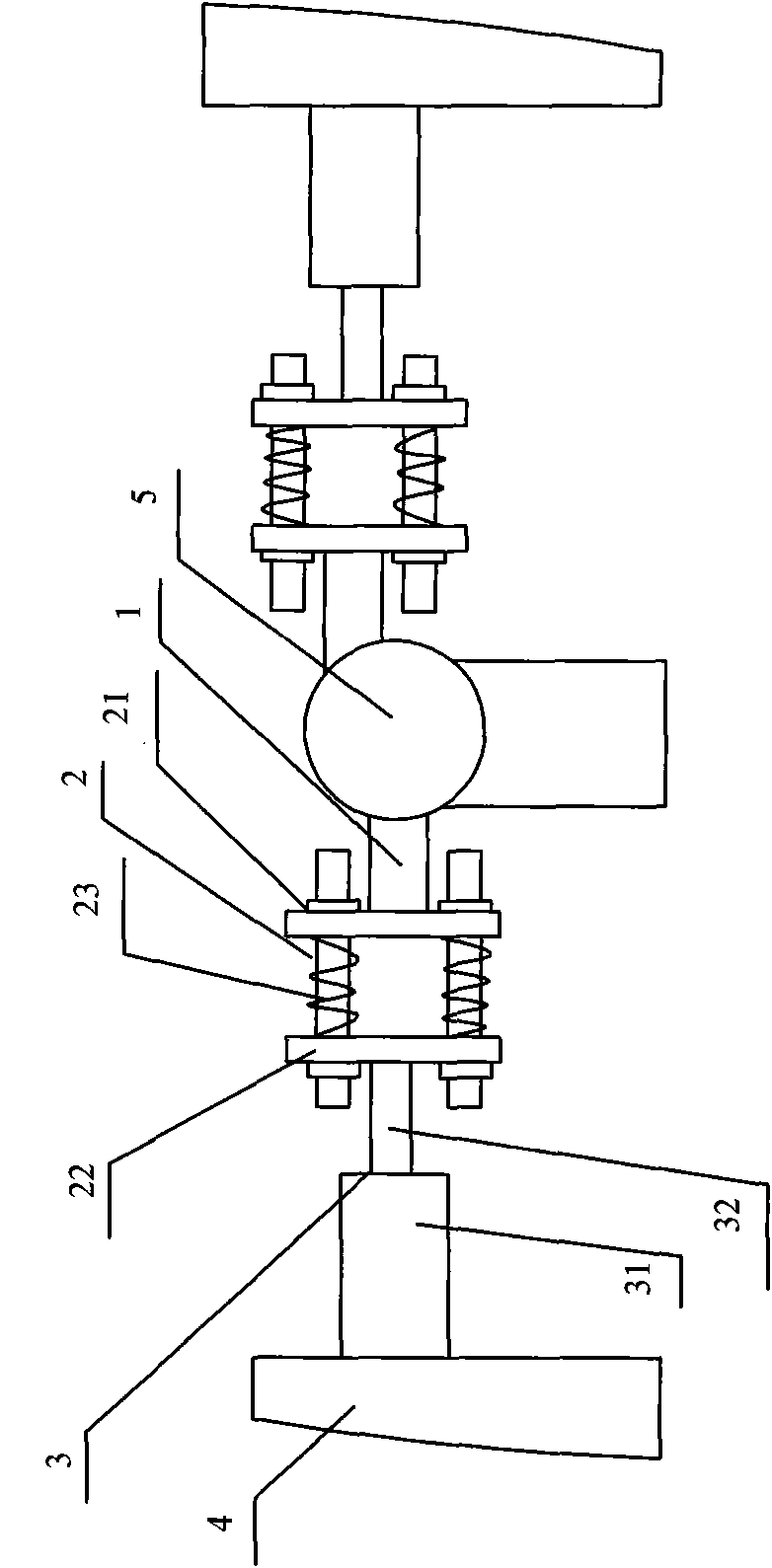

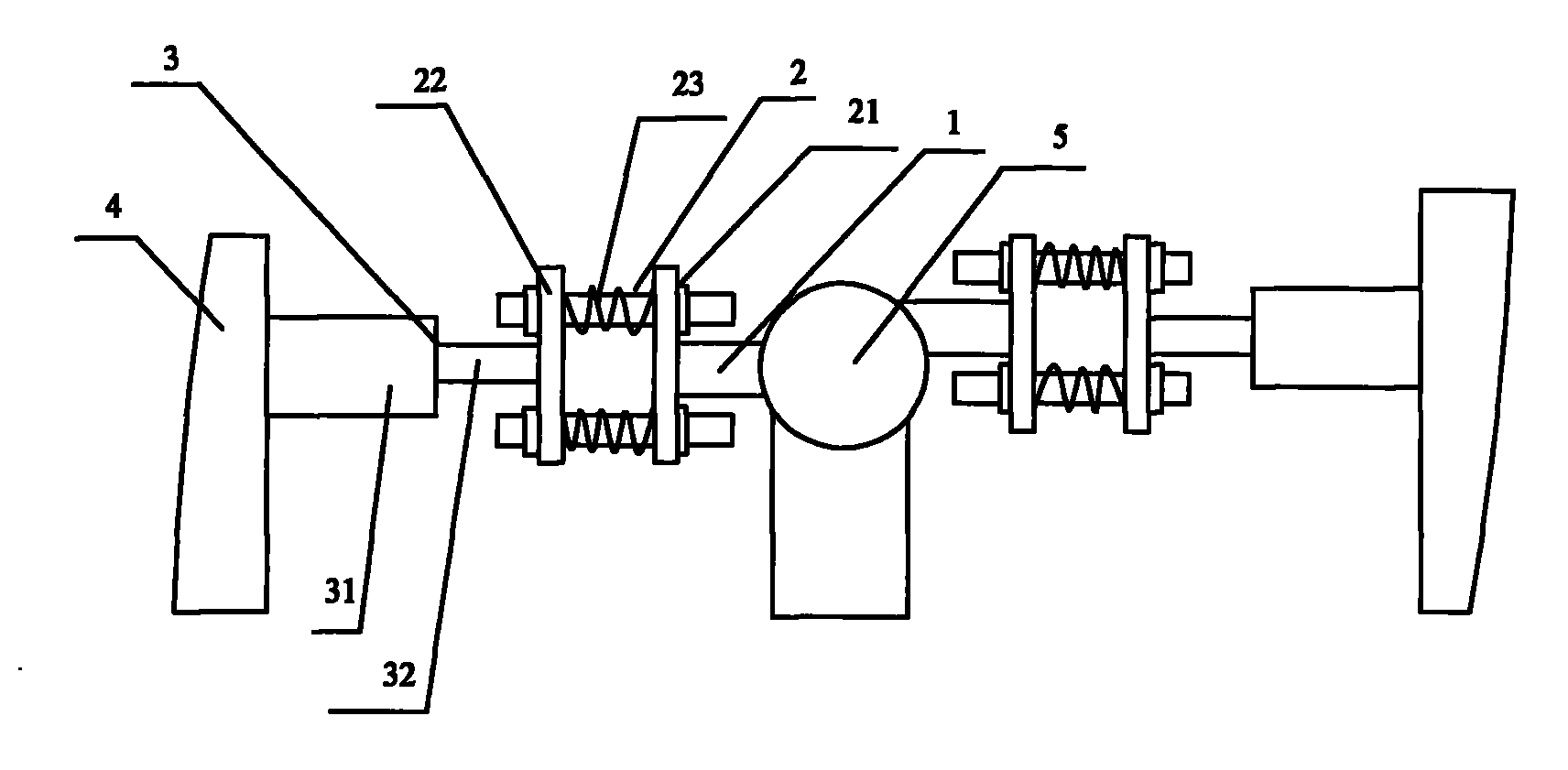

[0018] In order to further improve the conductive device, in this embodiment, the compression device 3 is used as an example for illustration. The present invention includes a brush 1, a connecting device 2, and a compression device 3. The compression device 3 is fixedly arranged on the electroplating On the equipment 4; one end of the connecting device 2 is fixedly connected to the brush 1, and the other end is fixedly connected to the pressing device 3. The cylinder device includes a cylinder body 31 and a push rod 32, and one end of the push rod 32 is arranged on the cylinder body 31, the outer periphery of the push rod 32 is in sealing fit with the inner peripheral surface of the cylinder 31, and the other end of the push rod 32 withstands the connecting device 2 and is fixedly connected with the connecting device 2 by fasteners or welding or other processes. The cylinder body 31 is fixed on the electroplating equipment through a positioning seat. When working, the brush 1...

Embodiment 2

[0020] In order to achieve the best effect of the present invention, the following technical solutions can be further adopted: the present invention includes a brush 1, a connecting device 2, and a pressing device 3, and the pressing device 3 is fixedly arranged on the electroplating equipment 4; the connecting device 2. One end is fixedly connected to the brush 1, and the other end is fixedly connected to the pressing device 3. The connecting device 2 includes a first pressing plate 21, a second pressing plate 22, and a spring 23. The first and second pressing plates 21, 22 are arranged in one body parallel to each other through fasteners, and the spring 23 is arranged between the first and second pressure plates 21, 22; On the inner surface of 22, the number of springs 23 is not limited, and can be single, double, or multiple, and can be specifically designed according to requirements, and the positions of springs 23 can be specifically distributed according to the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com