Latch for cork or plastic floor

A technology of plastic floor and cork, applied in the direction of floor, building, building structure, etc., can solve the problems of floor height difference, influence of slotting accuracy, distance uncertainty, etc., to achieve the effect of floor leveling and overcoming the effect of splicing height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

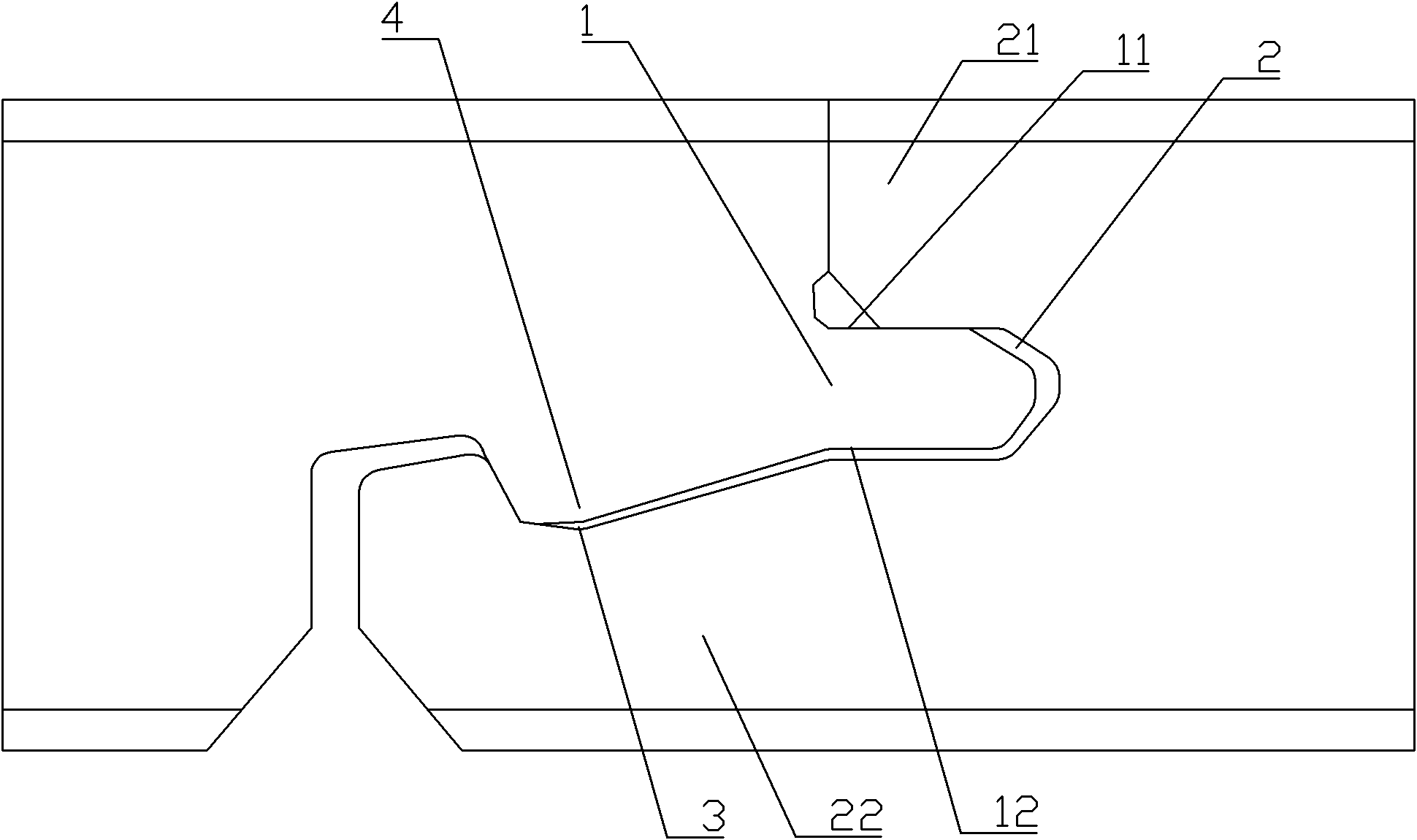

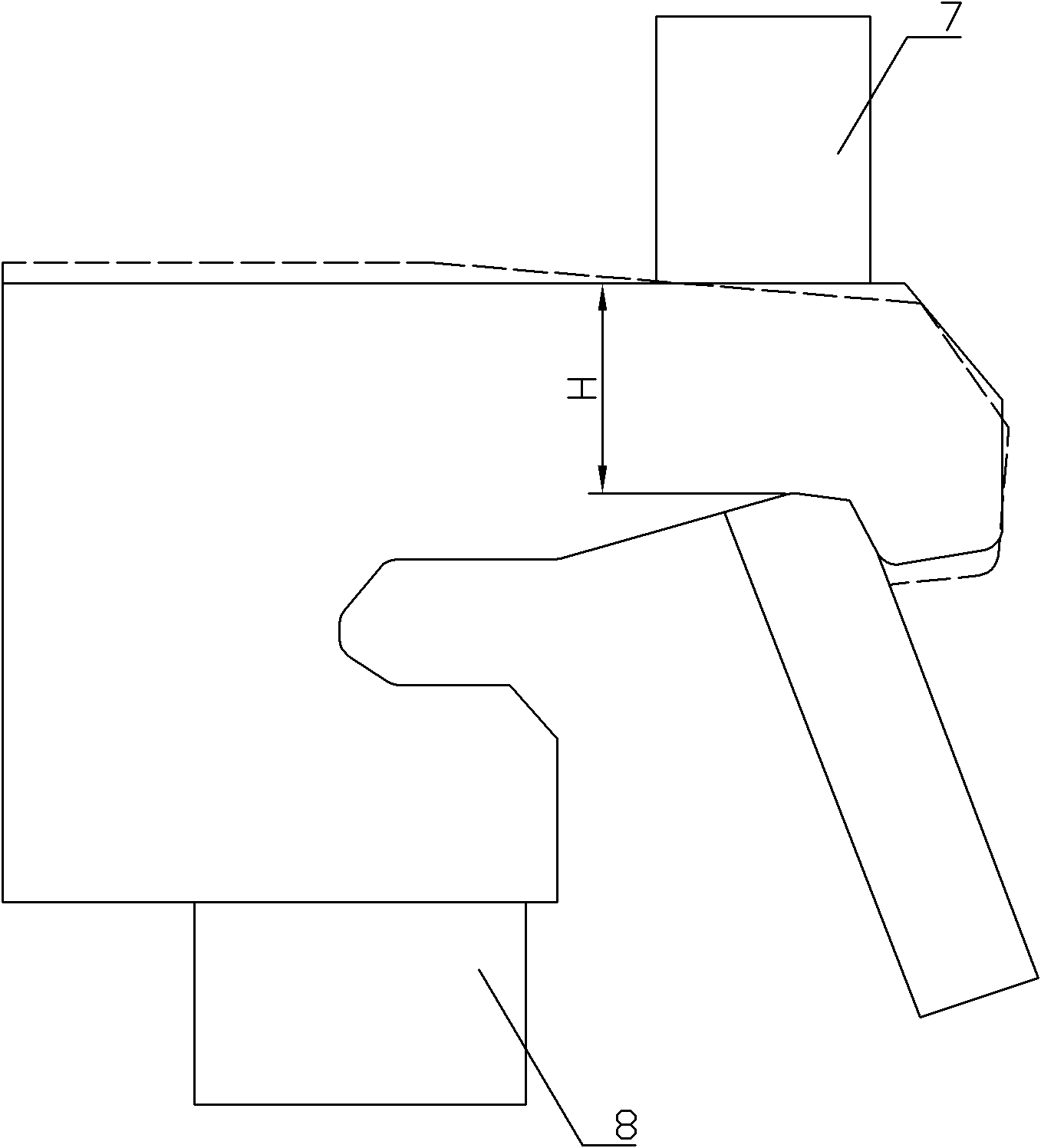

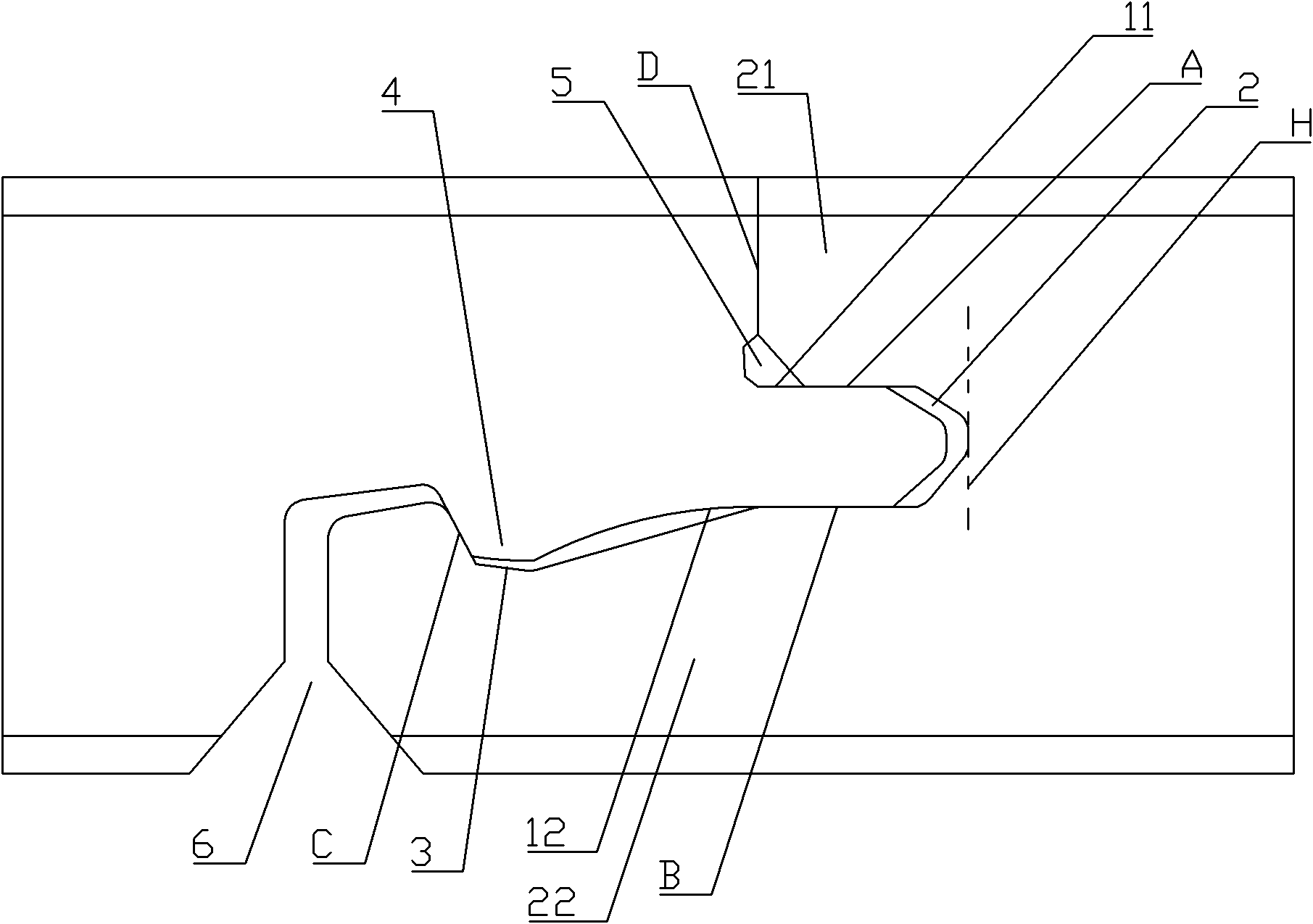

[0014] Now combined with image 3 The present invention will be described in further detail. The drawing is a simplified schematic diagram, which only illustrates the basic structure of the present invention in a schematic manner, so it only shows the structure related to the present invention.

[0015] Such as image 3 As shown, a lock for cork or plastic floor includes a tongue 1 and a groove 2.

[0016] The tongue and groove 2 has an upper tongue 21 and a lower tongue 22, the tongue 1 has an upper tongue surface 11 and a lower tongue surface 12, the length of the lower tongue 22 exceeds the upper tongue 21, and the lower tongue 22 has a recess 3, There are protrusions 4 on the lower tongue surface 12, the positions of the recesses 3 and the protrusions 4 are beyond the end surface of the upper tongue 21, the tongue 1 is inserted into the groove 2, the protrusion 4 is inserted into the recess 3, the tongue 1 and the groove 2 have a horizontal lock And vertical locking, the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com