Frequency conversion air conditioner for new energy passenger car

A technology for frequency conversion air conditioners and air conditioners, which is applied in the field of frequency conversion air conditioners, can solve the problems of difficulty in fan speed regulation, poor energy saving effect, and large space occupation, and achieves good safety and energy saving effect, active use and promotion, and occupies space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the inverter air conditioner for new energy passenger cars of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

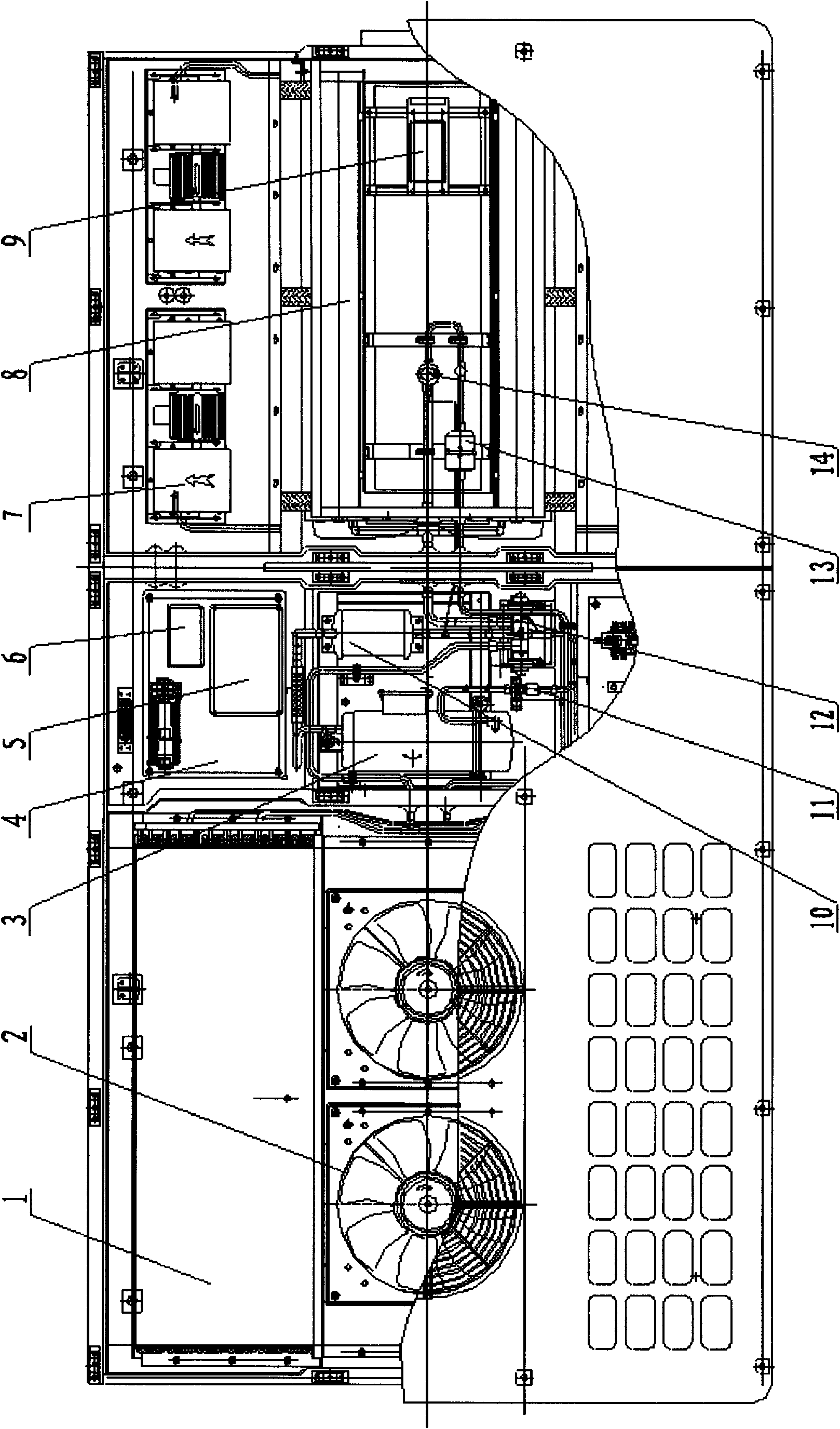

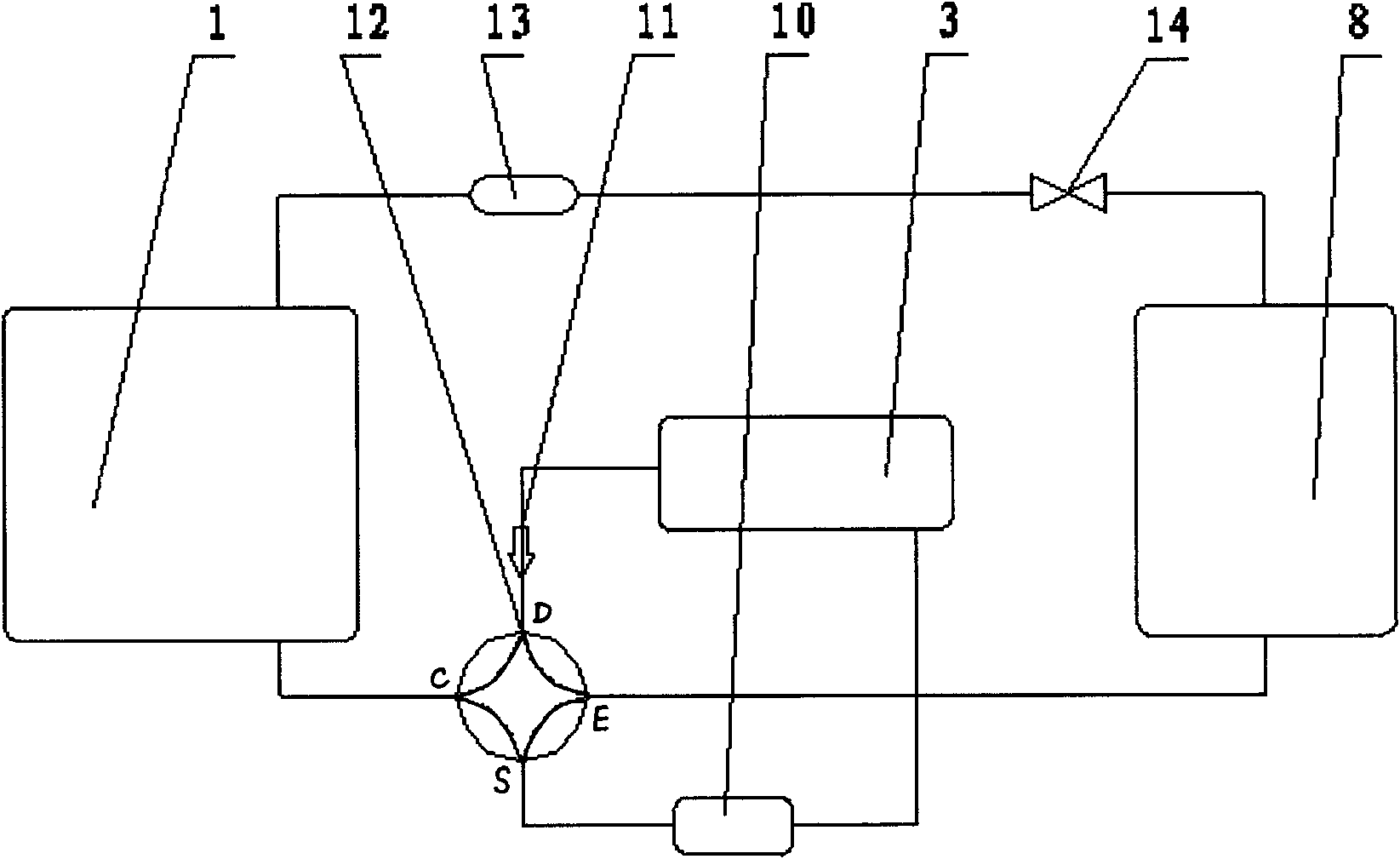

[0037] See attached figure 1 with 2 .

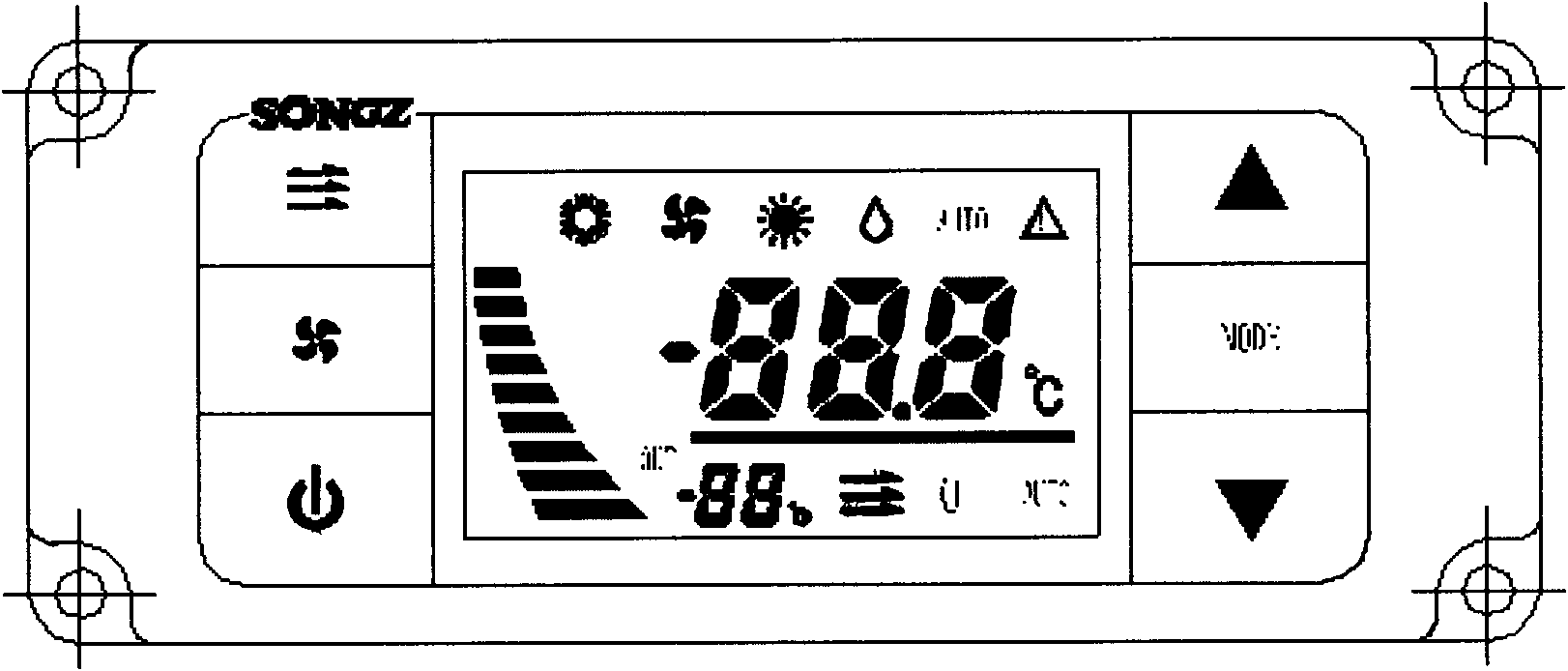

[0038] A frequency conversion air conditioner for new energy passenger cars, which is a top-mounted structure, consisting of a condenser 1, a condensation fan 2, a frequency conversion compressor 3, a control unit 4, a compressor frequency converter 5, a condensation fan frequency converter 6, an evaporation fan 7, an evaporation 8, evaporating fan frequency converter 9, gas-liquid separator 10, check valve 11, four-way reversing valve 12, dryer 13 and two-way expansion valve 14. Adopt a fully enclosed or semi-enclosed horizontal scroll frequency conversion compressor 3, and use two or one air pressure or suction type condensing fan 2, and set the frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com