Method and device for controlling temperature uniformity of heating roller

A technology of a control device and a control method, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems such as the failure of the control accuracy of the temperature uniformity of the heating roller to achieve uniform temperature rise and fall, and control temperature uniformity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

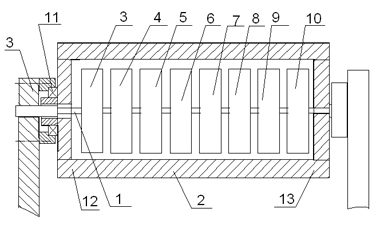

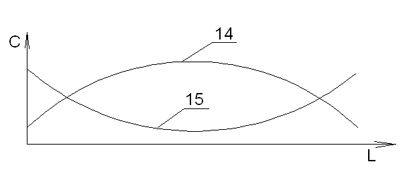

[0014] attached figure 1 An embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a method for controlling the temperature uniformity of a heating roller. The heating roller is heated by an electromagnetic heating method, and the heating roller is a hollow roller with a hollow center. The heating device is arranged in the hollow part of the heating roller; the electromagnetic heating device is more than three electromagnetic heating coils, and the temperature uniformity of the heating roller is controlled by controlling the calorific value of the electromagnetic heating coils respectively. Said controlling the temperature uniformity of the heating roller by respectively controlling the heat generation of the electromagnetic heating coil is to arrange the electromagnetic heating coil in the hollow part of the heating roller along the axial direction of the heating roller, and according to the heat di...

Embodiment 2

[0019] The principle of the second embodiment is the same as that of the first embodiment, except that the electromagnetic heating coils are arranged in odd numbers, such as 3, 5, 7, 9 and other odd numbers of electromagnetic heating coils. The electromagnetic heating coil is fixed in the heating roller 2 and rotates with the heating roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com