Analyzer for metal oxide film

An oxide film and analyzer technology, applied in the direction of material electrochemical variables, etc., can solve the problems of inapplicable large-scale macroscopic detection, small analysis area, and low interlayer resistance, so as to reduce the incidence of poor surface quality problems , good measurement stability and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

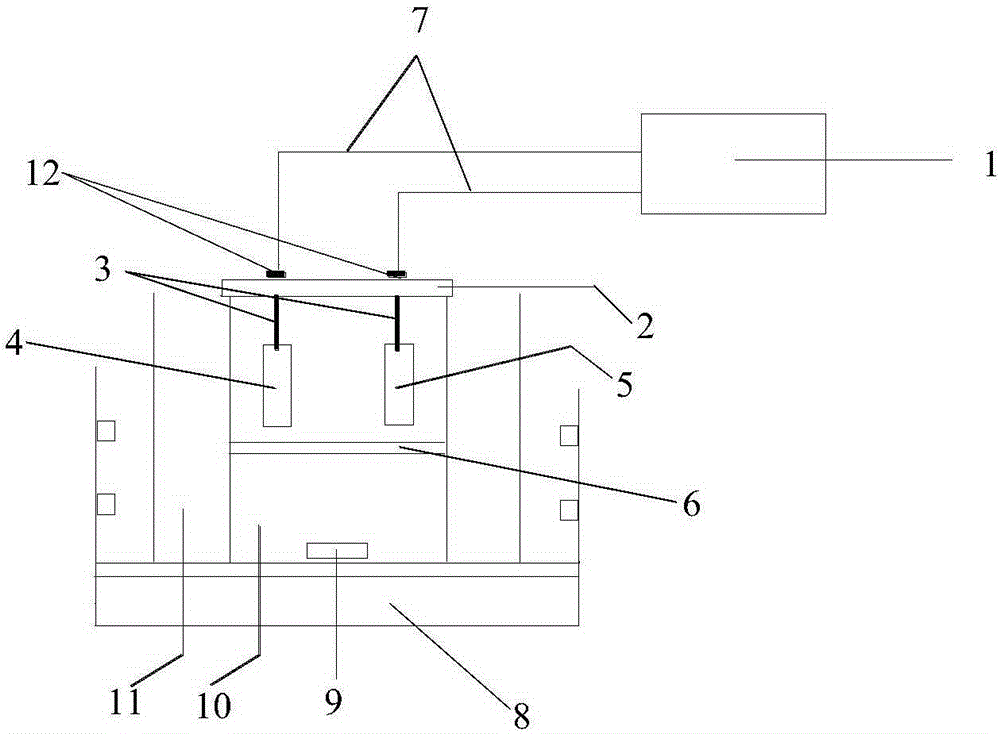

[0027] 1. Pour about 3000ml of water into the water tank 11, inject 400ml of sulfuric acid with a concentration of 8% into the acid tank 10, and immerse the acid tank in the water;

[0028] 2. The constant temperature magnetic stirrer 8 is energized, the acid is preheated, the set temperature is 40°C, and the rotation speed of the magnet 9 is 30 rpm;

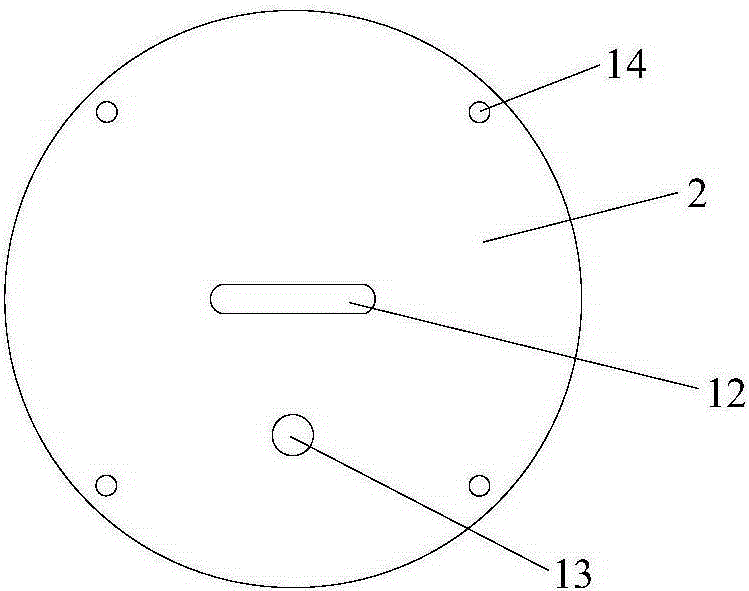

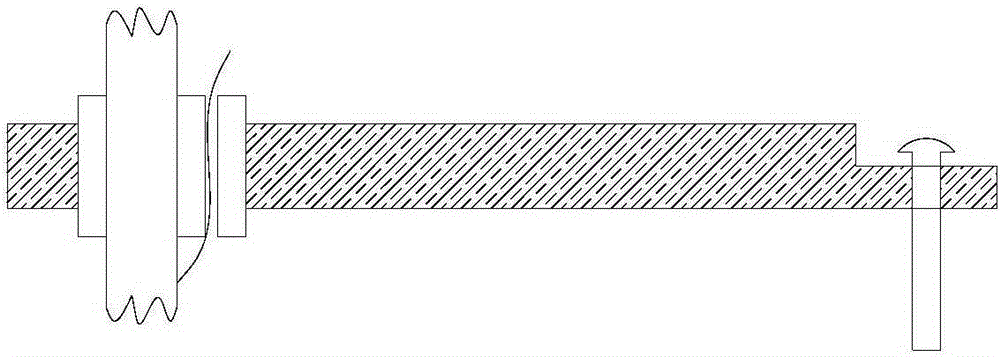

[0029] 3. Connect the copper guide rod 3 to the potentiometer 1 with the wire 7, the pole plates 4 and 5 are fixed on the copper guide rod 3 by bolts, and the copper guide rod 3 is fixed on the cover plate 2 by bolts;

[0030] 4. The cover plate 2 is covered on the acid tank 10, while the pole plates 4 and 5 are immersed in the acid, and the cover plate 2 is fixed on the acid tank 10 with bolts;

[0031] 5. Turn on the potentiometer 1 to start measurement. When the value displayed on the potentiometer is stable at 0mV, the reaction is completed, and the power is turned off to end the measurement.

Embodiment 2

[0033] 1, inject about 4000ml water in the water tank 11, inject 500ml in the acid tank 10, the concentration is 10% sulfuric acid, and the acid tank 10 is immersed in water;

[0034] 2. The constant temperature magnetic stirrer 8 is energized, the acid is preheated, the set temperature is 40°C, and the rotation speed of the magnet 9 is 40 rpm;

[0035] 3. Connect the copper guide rod 3 to the potentiometer 1 with the wire 7, the pole plates 4 and 5 are fixed on the copper guide rod 3 by bolts, and the copper guide rod 3 is fixed on the cover plate 2 by bolts;

[0036] 4. The cover plate 2 is covered on the acid tank 10, while the pole plates 4 and 5 are immersed in the acid, and the cover plate 2 is fixed on the acid tank 10 with bolts;

[0037] 5. Turn on the potentiometer 1 to start measurement. When the value displayed on the potentiometer is stable at 0mV, the reaction is completed, and the power is turned off to end the measurement.

Embodiment 3

[0039] 1, inject about 4000ml water in the water tank 11, inject 600ml in the acid tank 10, the concentration is 12% sulfuric acid, and the acid tank 10 is immersed in water;

[0040] 2. The constant temperature magnetic stirrer 8 is energized, the acid is preheated, the set temperature is 40°C, and the rotation speed of the magnet 9 is 40 rpm;

[0041] 3. Connect the copper guide rod 3 to the potentiometer 1 with the wire 7, the pole plates 4 and 5 are fixed on the copper guide rod 3 by bolts, and the copper guide rod 3 is fixed on the cover plate 2 by bolts;

[0042] 4. The cover plate 2 is covered on the acid tank 10, while the pole plates 4 and 5 are immersed in the acid, and the cover plate 2 is fixed on the acid tank 10 with bolts;

[0043] 5. Turn on the potentiometer 1 to start measurement. When the value displayed on the potentiometer is stable at 0mV, the reaction is completed, and the power is turned off to end the measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com