Integrated high-frequency soldering iron core

A soldering iron core and high-frequency technology, applied in the field of integrated high-frequency soldering iron core, can solve the problems such as the inability to increase the return temperature power, achieve fast and accurate temperature compensation, improve heat transfer efficiency, and avoid large overshoot effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

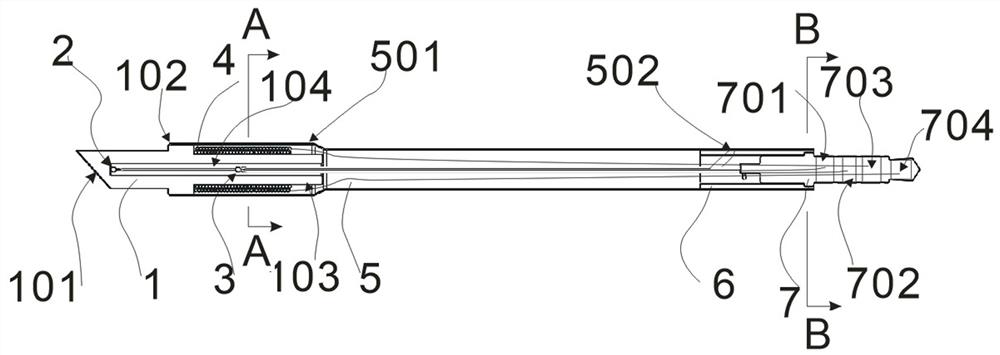

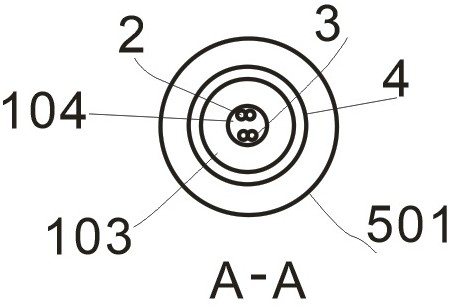

[0036] Such as Figure 1-3 As shown, the present invention is an integrated high-frequency soldering iron core, which includes a soldering iron tip 1, the soldering iron tip 1 is made of copper, the surface is electroplated with an iron layer, and the appearance of other iron layers except the working surface 101 is plated with a nickel layer. Chromium electroplating is then performed on places other than the working surface 101 of the soldering iron tip.

[0037] For the convenience of expression, the soldering iron tip 1 is divided into four parts, the working surface 101, the connection step 102 between the soldering iron tip 1 and the steel pipe jacket 5, the tail pipe 103 at the rear of the soldering iron tip 1, and the tail pipe 103 is used to wind the high-frequency induction Coil 4 is also the final heating part in this case;

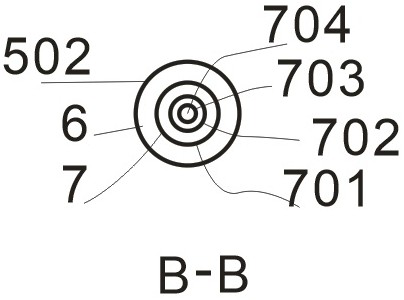

[0038] The tail of the soldering iron head 1 is connected to the outer steel pipe 5, and the tail of the outer steel pipe 5 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com