Epitaxial growth method for improving inner quantum efficiency of GaN-based LED

A light-emitting diode, internal quantum efficiency technology, applied in gaseous chemical plating, coatings, electrical components, etc., can solve problems such as low internal quantum efficiency and brightness, influence of material crystal quality, and decline in radiation recombination efficiency, so as to improve luminescence. Efficiency and Brightness, Enhanced Quantum Localization Effect, Increased Effect of Internal Quantum Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The epitaxial equipment used in this embodiment is a commercial machine produced by Germany AIXTRON company, and the model is Thomsaswan31x2'.

[0019] The V group source used was ammonia (NH 3 ), the Group III metal-organic source materials are trimethylgallium (TMGa) and trimethylindium (TMIn).

[0020] Carrier gas is N 2 or H 2 .

[0021] NH 3 , trimethylgallium (TMGa) and trimethylindium (TMIn) flow rates are 30 standard liters / minute (sl / m), 260 micromoles / minute (μmol / m) and 300 micromoles / minute (μmol / m) m).

[0022] The reaction chamber pressure is 300 Torr.

[0023] Steps:

[0024] After loading the 2-inch sapphire substrate into the MOCVD growth equipment, it is baked at high temperature in sequence to grow a low-temperature gallium nitride buffer layer, a gallium nitride nucleation layer, and an n-type gallium nitride layer.

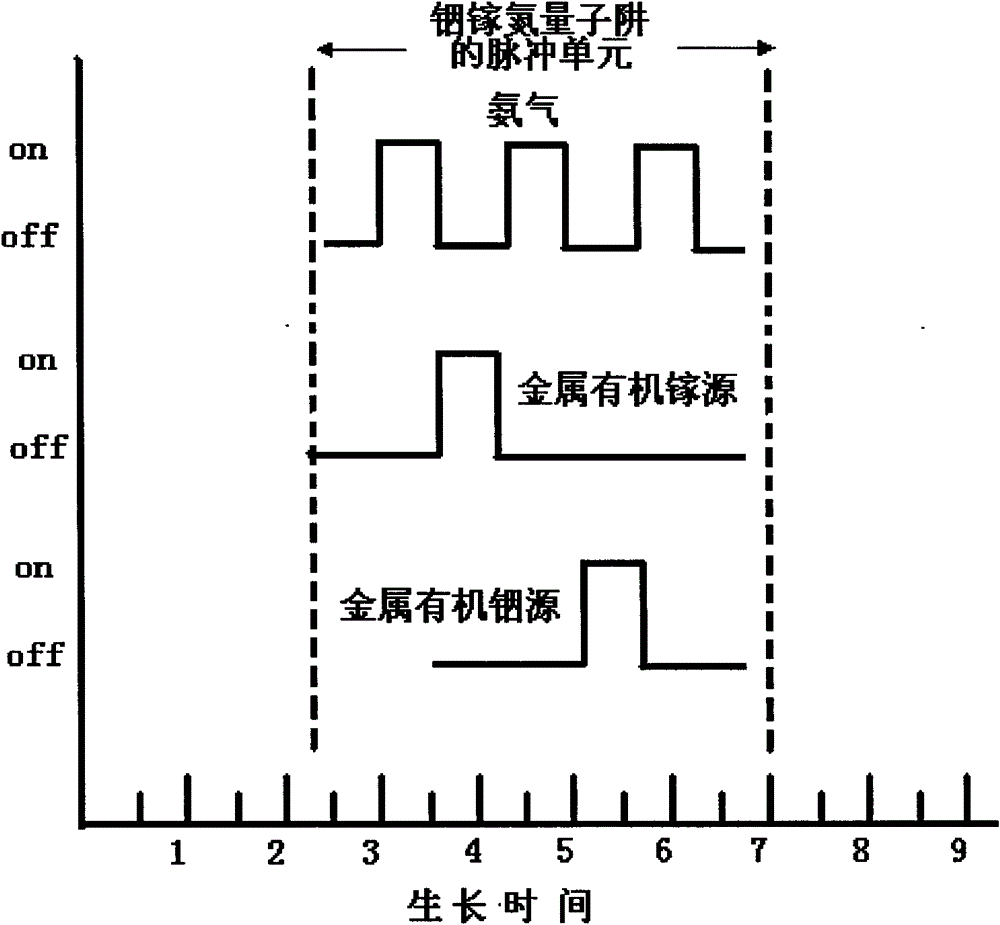

[0025] Then grow the InGaN / GaN light-emitting active region. First, the temperature of the sapphire substrate was lowered to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com