Punch formed metal bipolar plate of proton exchange membrane fuel cell

A technology of metal bipolar plates and proton exchange membranes, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex assembly of bipolar plates, and achieve the effects of slowing down deformation, uniform cooling water distribution, and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

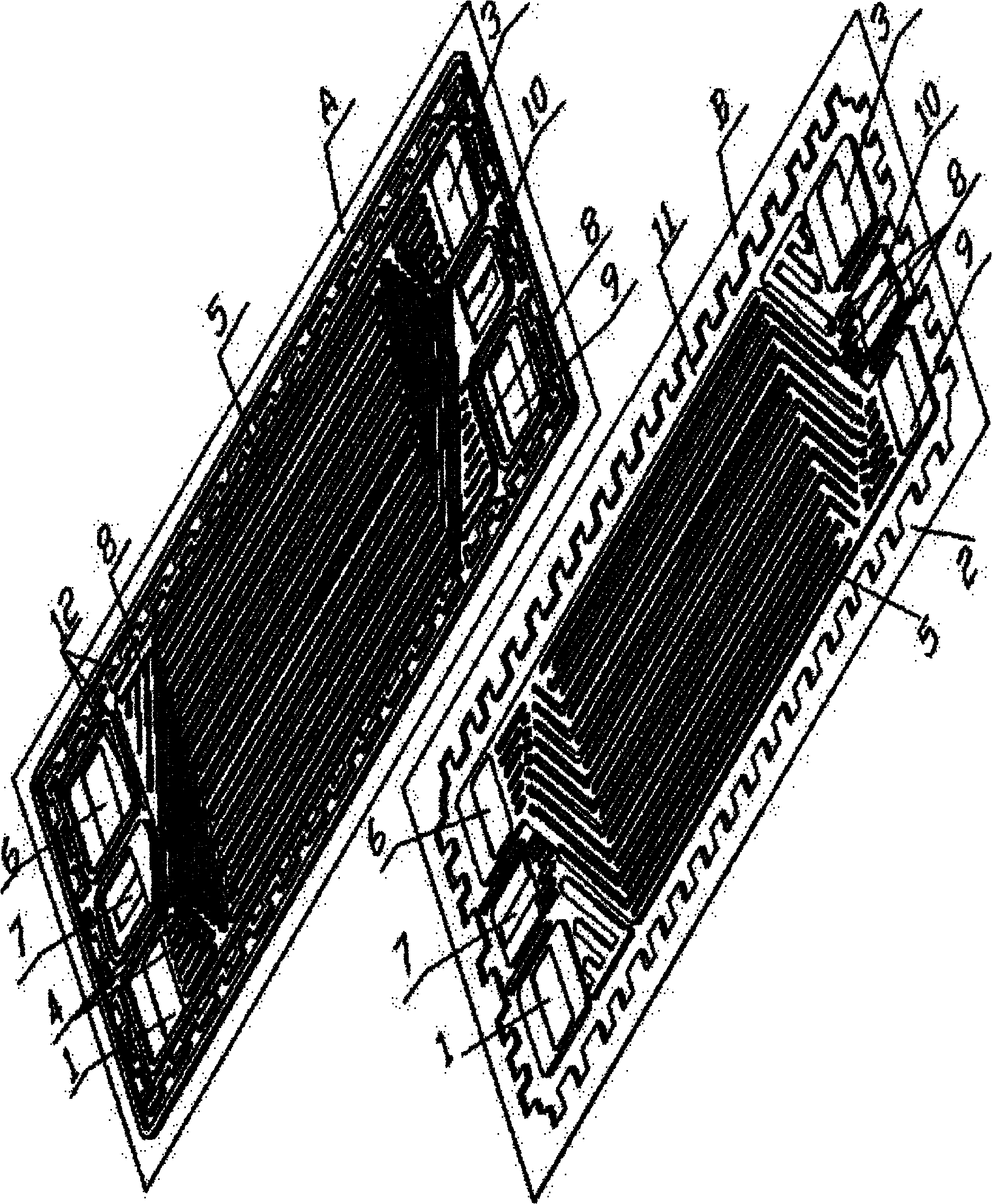

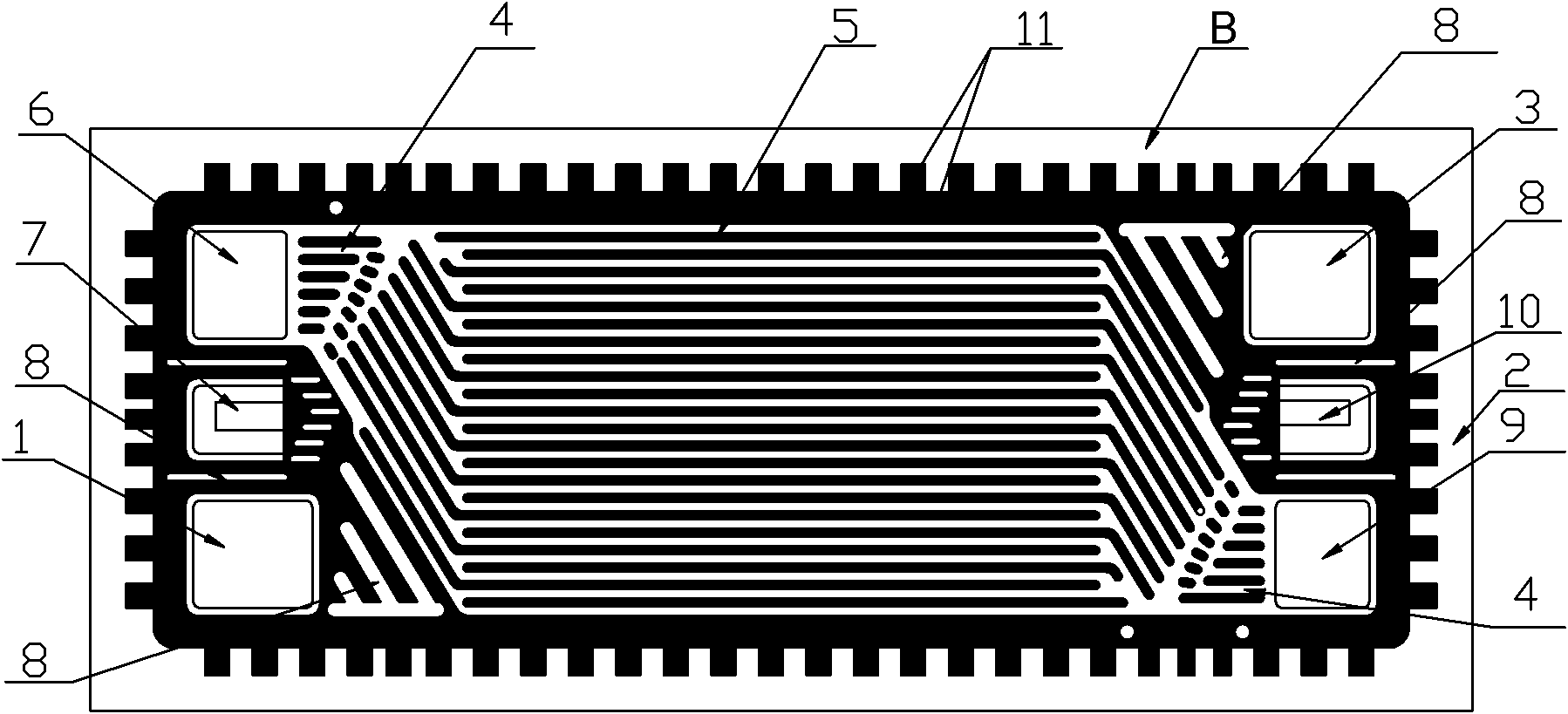

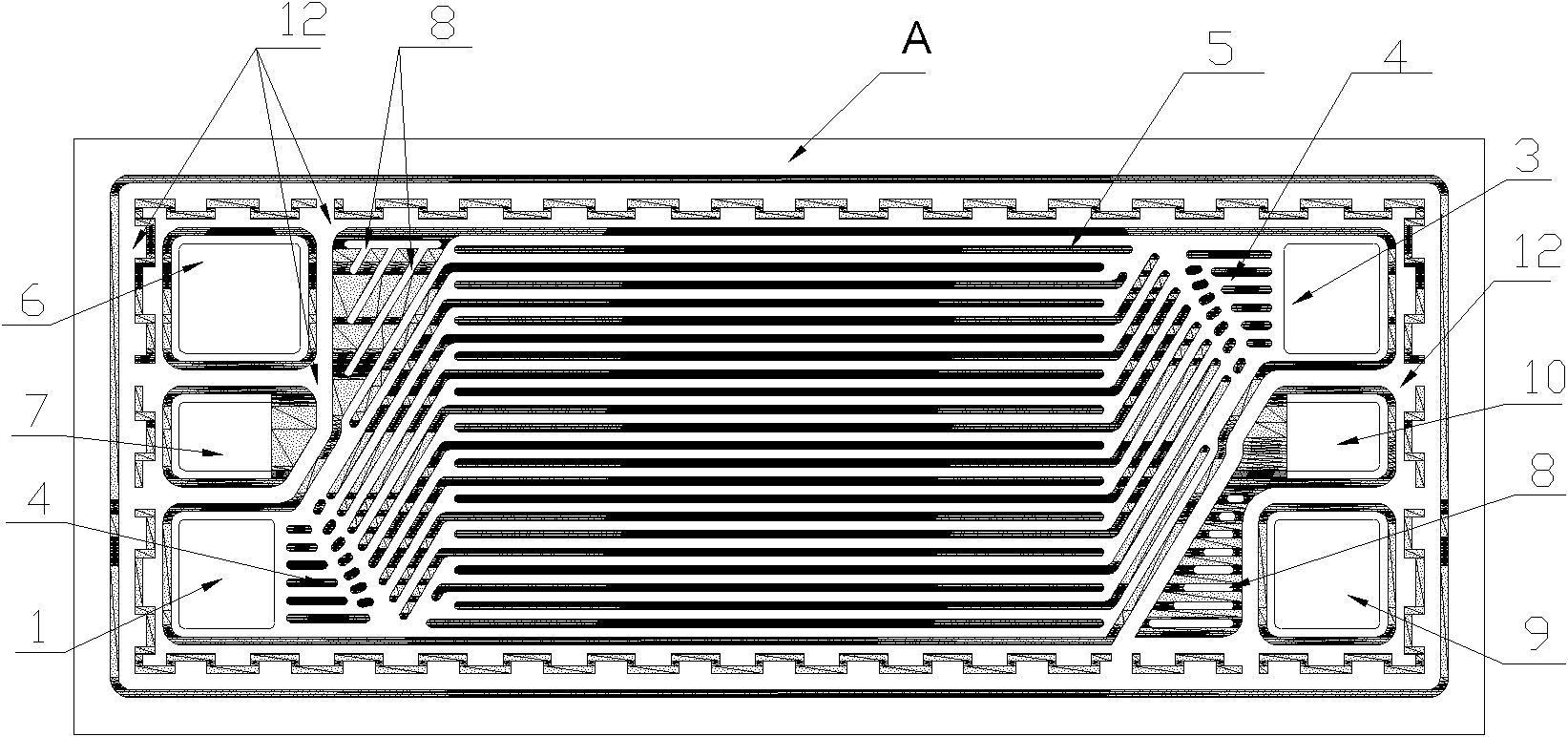

[0043] Such as Figure 1-5 The stamped proton exchange membrane fuel cell metal bipolar plate is composed of the second metal plate A and the first metal plate B stamped and formed by metal sheet through laser welding.

[0044] Such as figure 1 As shown in the exploded view, the left and right ends of the second metal plate A and the first metal plate B are provided with air outlet 1, air inlet 3, cooling water inlet 7, cooling water outlet 10, hydrogen inlet 6, hydrogen outlet 9, cooling A cooling water chamber is provided at the water inlet and outlet; flow field flow channels 5 composed of concave-convex grooves are arranged in the middle area of the front and back flow fields of the two plates, wherein the positive concave-convex grooves of the first metal plate B form the anode flow field, The concave-convex grooves on the front of the second metal plate A form a cathode flow field, and the opposite sides of the two plates cooperate with each other to form a cooling wa...

Embodiment 2

[0053] The metal bipolar plate of the proton exchange membrane fuel cell formed by stamping is formed by the cooperation of two second metal plates A with the same structure stamped and formed by metal sheet; figure 1 similarly, just change the figure 1 It is sufficient to replace the first metal plate B with the second metal plate A, and the others are reserved, so no additional drawings are given.

[0054] Such as Figure 3-5 As shown, the left and right ends of the second metal plate A are provided with an air outlet 1, an air inlet 3, a cooling water inlet 7, a cooling water outlet 10, a hydrogen inlet 6, and a hydrogen outlet 9, and a cooling water outlet is provided at the cooling water inlet and outlet. Water cavity; the middle area of the front and back flow fields of the two plates is provided with a flow field channel 5 composed of concave-convex grooves, wherein, the positive concave-convex grooves of one second metal plate A form the anode flow field, and the ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com