High-accuracy antenna reflecting surface panel and manufacturing method thereof

A reflective surface, high-precision technology, applied in antennas, electrical components, etc., can solve the problems of complex process, manual calibration, large internal stress, etc., to achieve the effect of simple and convenient process, increase strength and rigidity, and reduce internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in further detail:

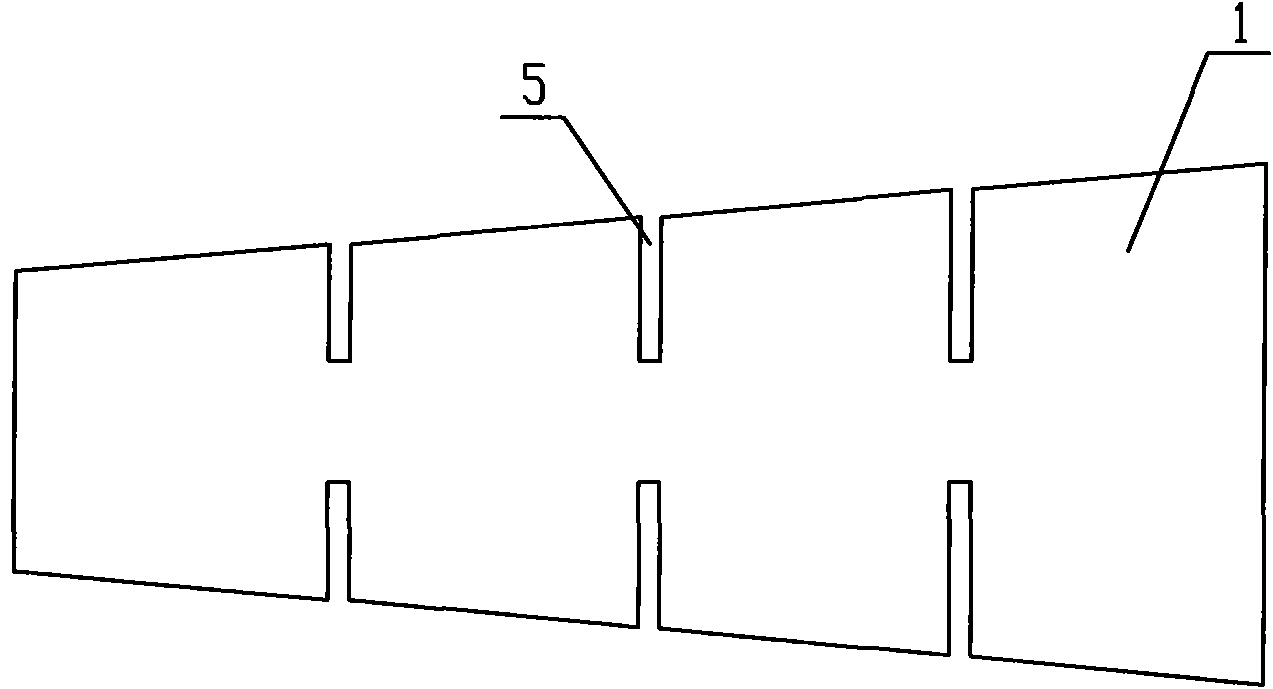

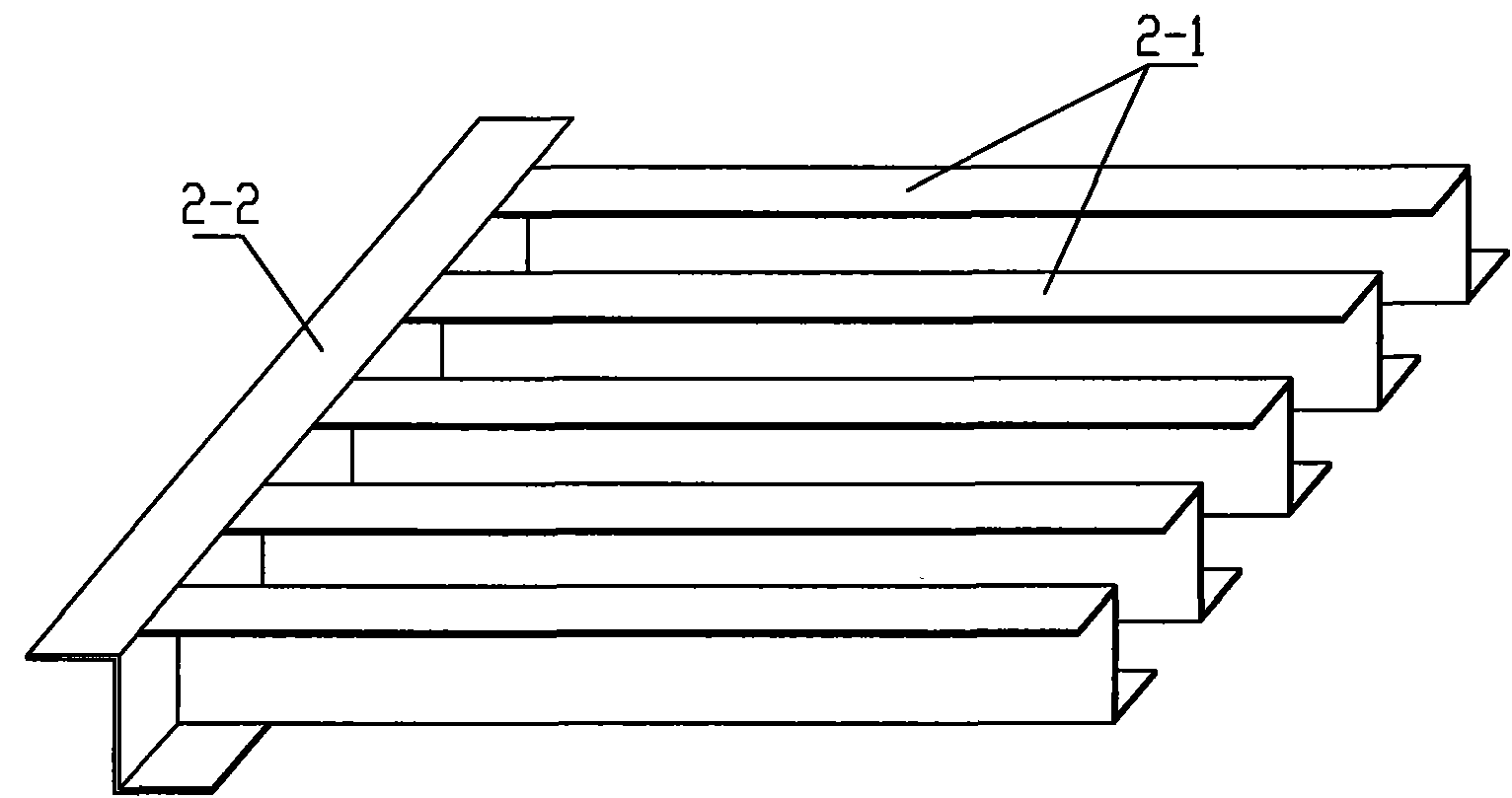

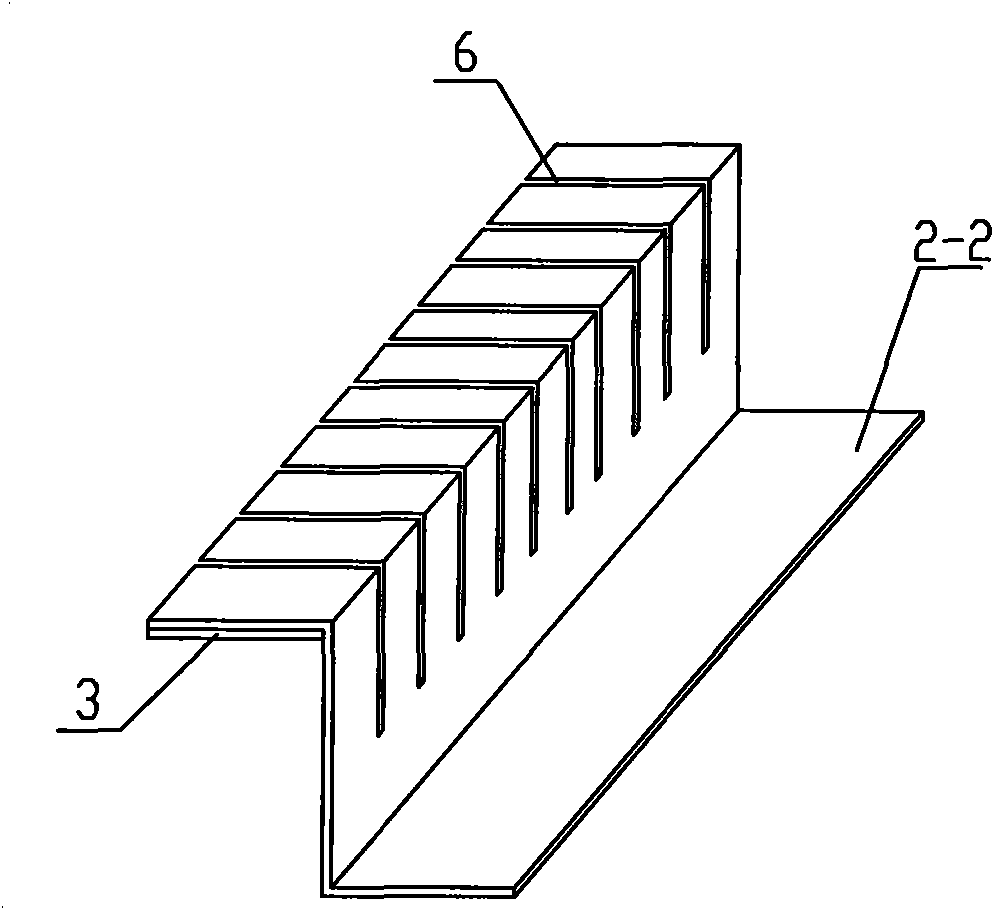

[0039] Such as Figure 1 to Figure 7As shown, the antenna reflector panel of the present invention comprises a supporting rib frame composed of skin 1, 4 Z-shaped bar ring rib beams 2-1 and 2 Z-shaped bar longitudinal rib beams 2-2; the skin 1 is fan-shaped, and the skin The front and back surfaces of 1 are the reflection surface and the support surface respectively, the Z profile ring reinforcement beam 2-1 is arranged along the circumferential direction of the skin 1, and the Z profile longitudinal reinforcement beam 2-2 is arranged along the radial direction of the skin 1, consisting of five The supporting rib frame composed of Z profile ring rib beam and two Z profile longitudinal rib beams corresponds to the shape of the support surface of skin 1, and the two are bonded and solidified by adhesive to form a whole; the radial direction on both sides of skin 1 Thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com