Hard combined mask for changing disconnector

A technology of shielding cover and knife gate, applied in switchgear, electrical components, etc., can solve the problems of distracting operators, decreased insulation performance, and many shielding steps, etc., to meet the requirements of live work, good insulation performance, and mechanical performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

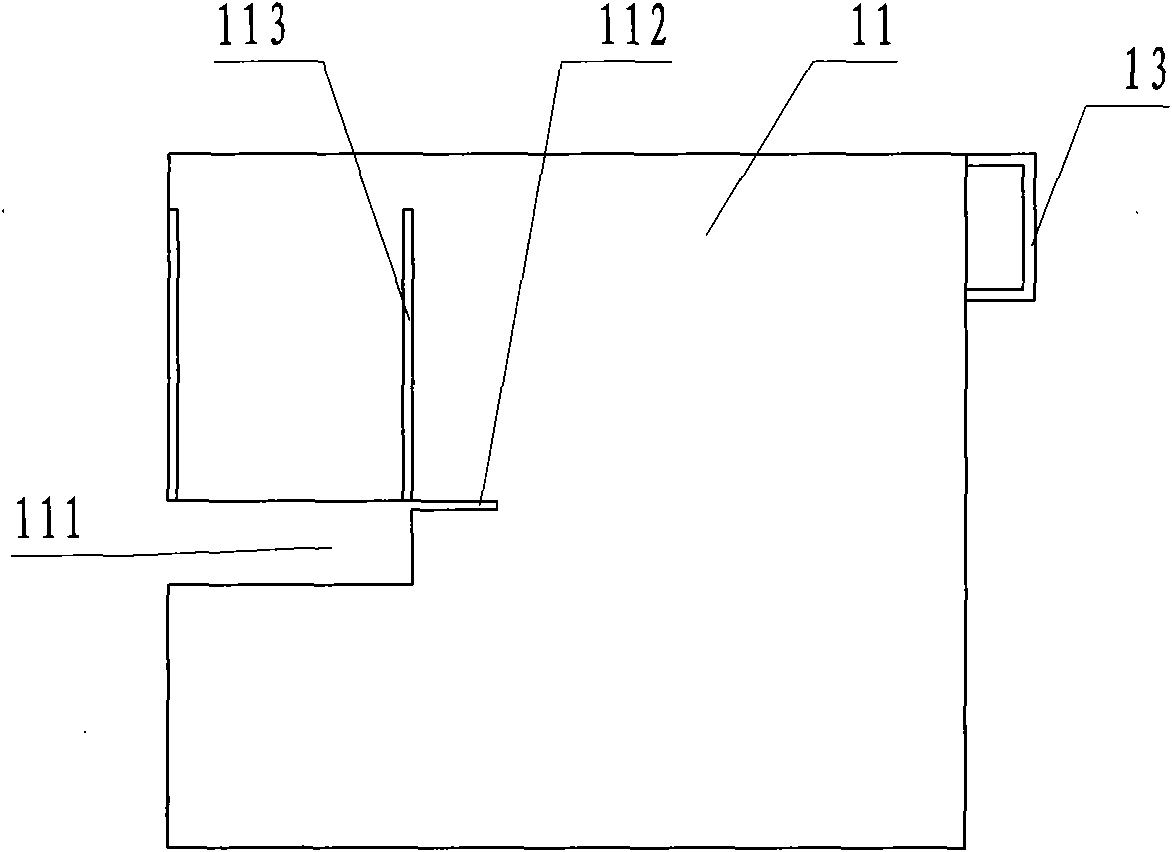

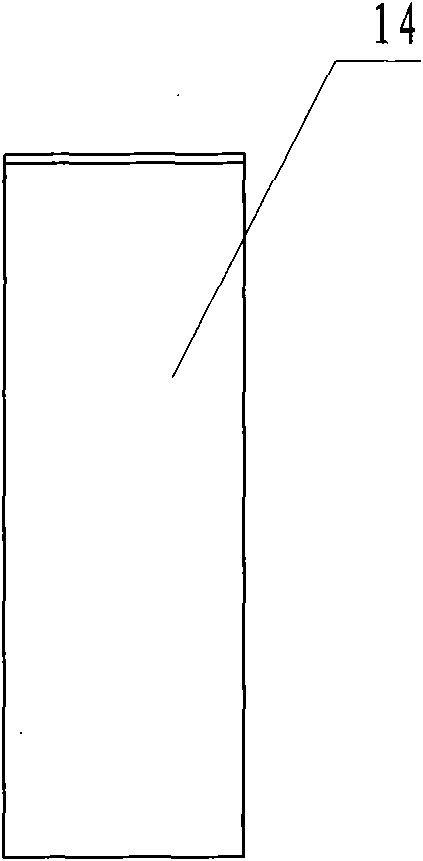

[0044] a kind of like Figure 1-6 The shown knife-gate isolation baffle 1 includes an insulating plate 11, and a bar-shaped groove 111 that can be snapped into a cross-arm is provided on one side of the insulating plate, and an L-shaped groove along the bottom of the bar-shaped groove is provided with a One side of the opening groove and the bayonet 112 that the bottom edge extends, the described knife gate isolating baffle plate also includes an L-shaped plug 12, and an L-shaped plug is provided at the angle of the L-shaped plug. The two angled sides are all vertical, and can be snapped into the L-shaped card slot 121 of the insulating plate. On the direction that the insulating plate is perpendicular to the bar-shaped groove, a slide that is equal to or slightly larger than the depth direction of the bar-shaped groove is provided. Road 113, the knife gate isolating baffle plate also includes inserting plates 14 that can be inserted into the slideways on both sides of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com