Folding aerodyne

A folding and flying car technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of physical exertion, inconvenient portability, and large space occupation, and achieve the effect of ensuring construction safety, ensuring operating posture, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

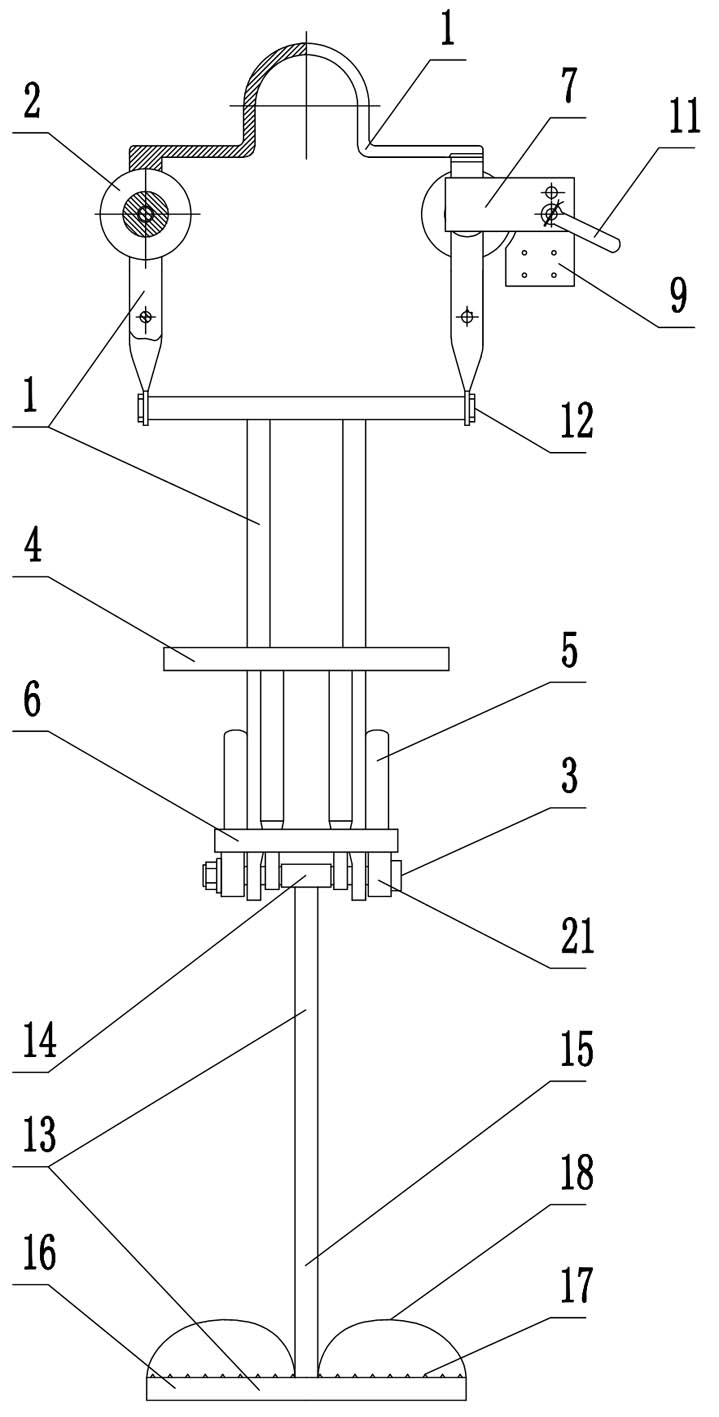

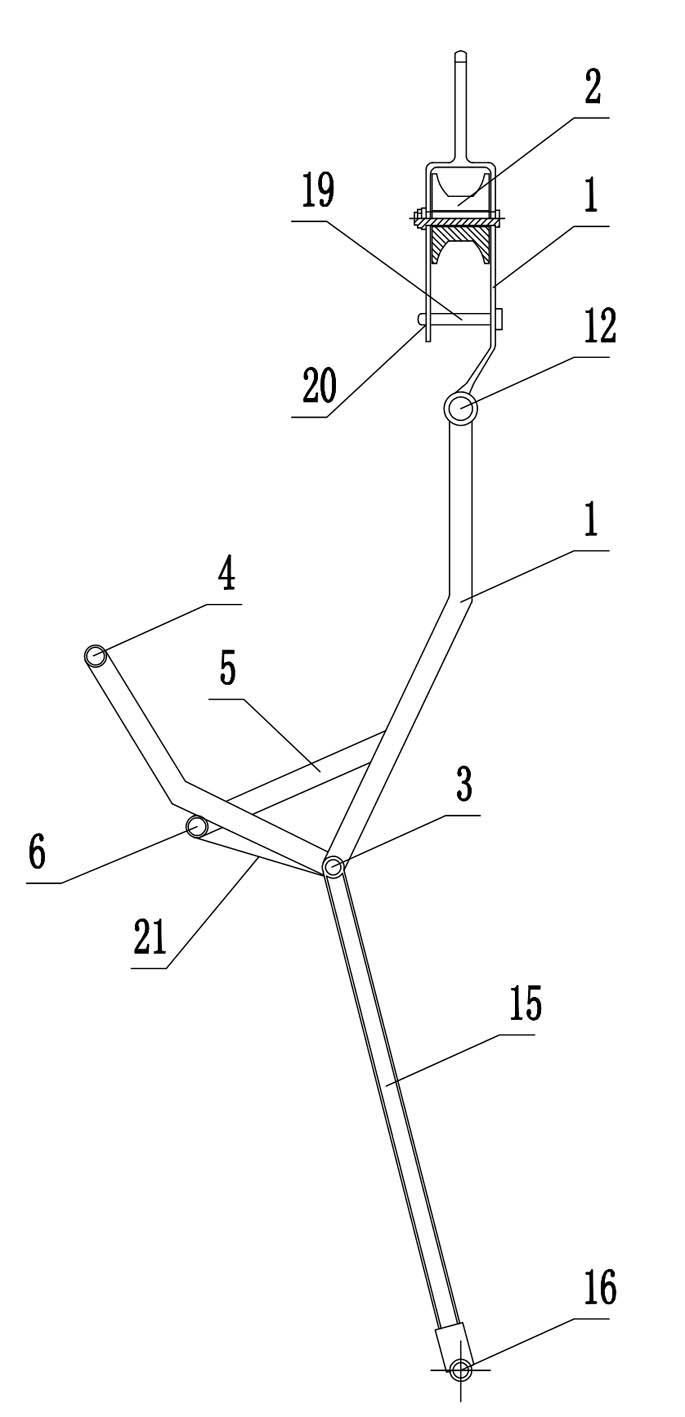

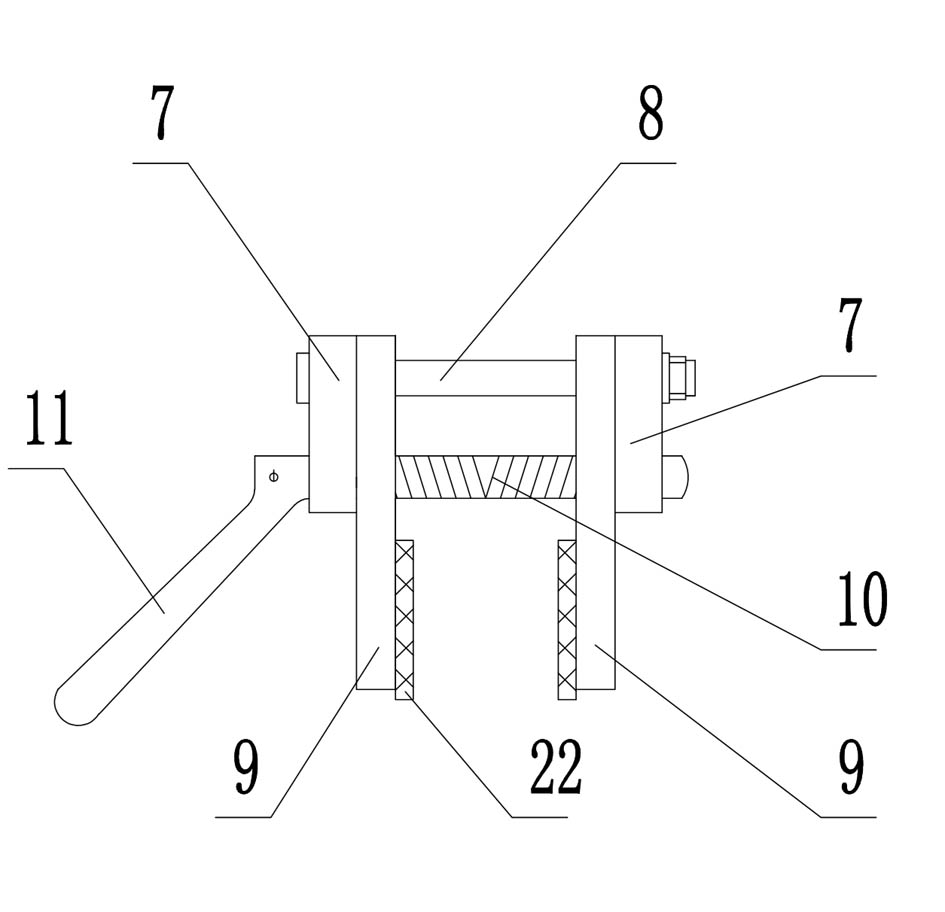

[0032] Such as figure 1 As shown, the folding flying car includes a hanger 1, the hanger 1 is formed by connecting a longitudinal bar and a cross bar, and the hanger 1 is divided into upper and lower parts, and these two parts are hinged together by a hinge shaft 12. The upper part of the hanger 1 includes a bracket that is fixedly connected by a cross bar and two longitudinal bars, each longitudinal bar is bent into an "n" shape, and support wheels 2 are installed between the two arms of the longitudinal bar. The supporting wheels 2 are arranged horizontally at intervals, and the hubs of the two supporting wheels 2 are located in the same plane, so that the two supporting wheels 2 can smoothly roll on the same electric wire. The support arm below the support wheel 2 is also provided with a limit hole 20, and the limit pin 19 is inserted in the limit hole 20. After the support wheel 2 is hung on the electric wire, the limit pin 19 is inserted into the limit hole 20. In this w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com