Apparatus for conveying electronic element

A technology for electronic components and conveying devices, which is applied to electrical components, electrical components, conveyor objects, etc., can solve the problems of low conveying efficiency, electronic component adsorption, and increased time required for placement, so as to reduce the number of components and shorten the conveying time. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

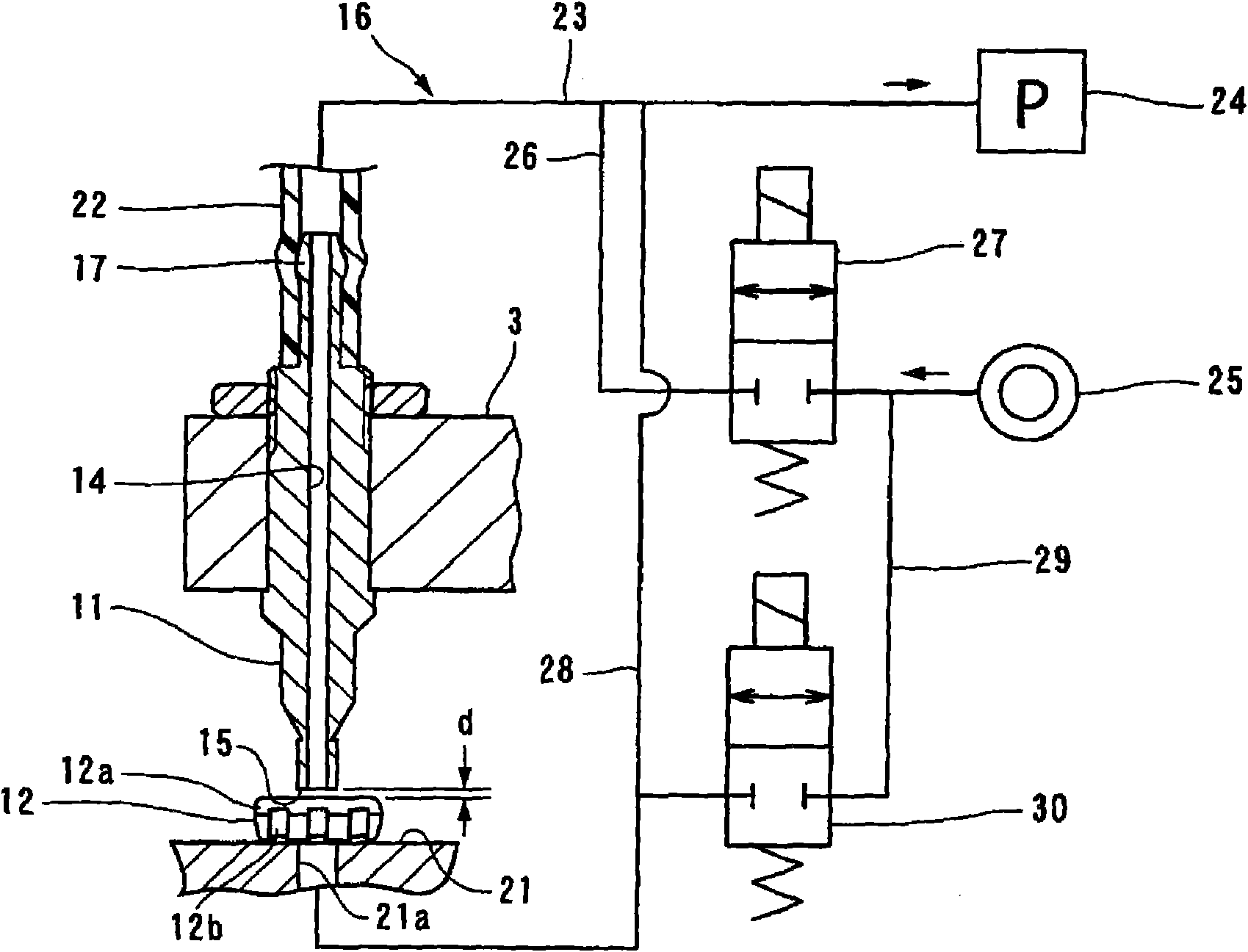

[0100] The electronic component 12 conveyed by the conveying device 1 shown in the above embodiment has a weight of 3 g or less, and the protruding length of the lead 12 b protruding downward from the bottom surface of the packaging portion 12 a is 0.1 mm or less. In addition, the vacuum pressure when the pick-and-place device 11 picks up the electronic component 12 is -40~-60kpa (absolute vacuum is -101.3kpa).

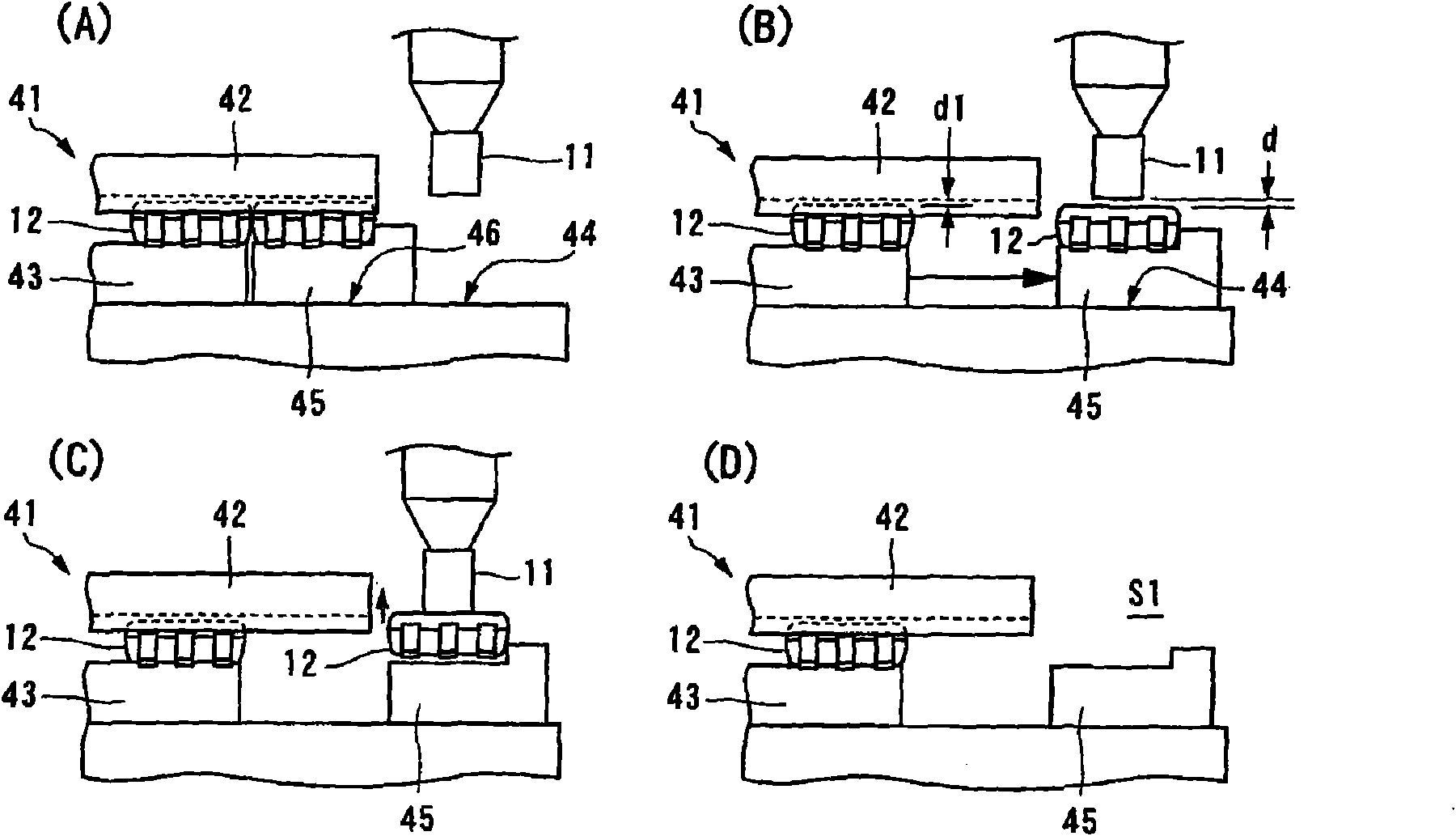

[0101] The gap d between the slider 45 of the electronic component supply unit 41 and the suction pick-and-place device 11 was 0.2 mm.

[0102] The gap d between the electronic component 12 held by the support member 53 of the labeling device 7 and the suction pick-and-place device 11 is 0.4 mm.

[0103] In addition, these numerical values are just an example, and can be changed suitably according to the kind of the electronic component 12 used as a target.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com