Shock absorbing apparatus

A shock absorption and shock absorption technology, which is applied in transportation and packaging, pedestrian/passenger safety arrangement, superstructure subassembly, etc., can solve the problems of unstable conditions, increased working hours, and inability to produce height dimensions, etc., to achieve the shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

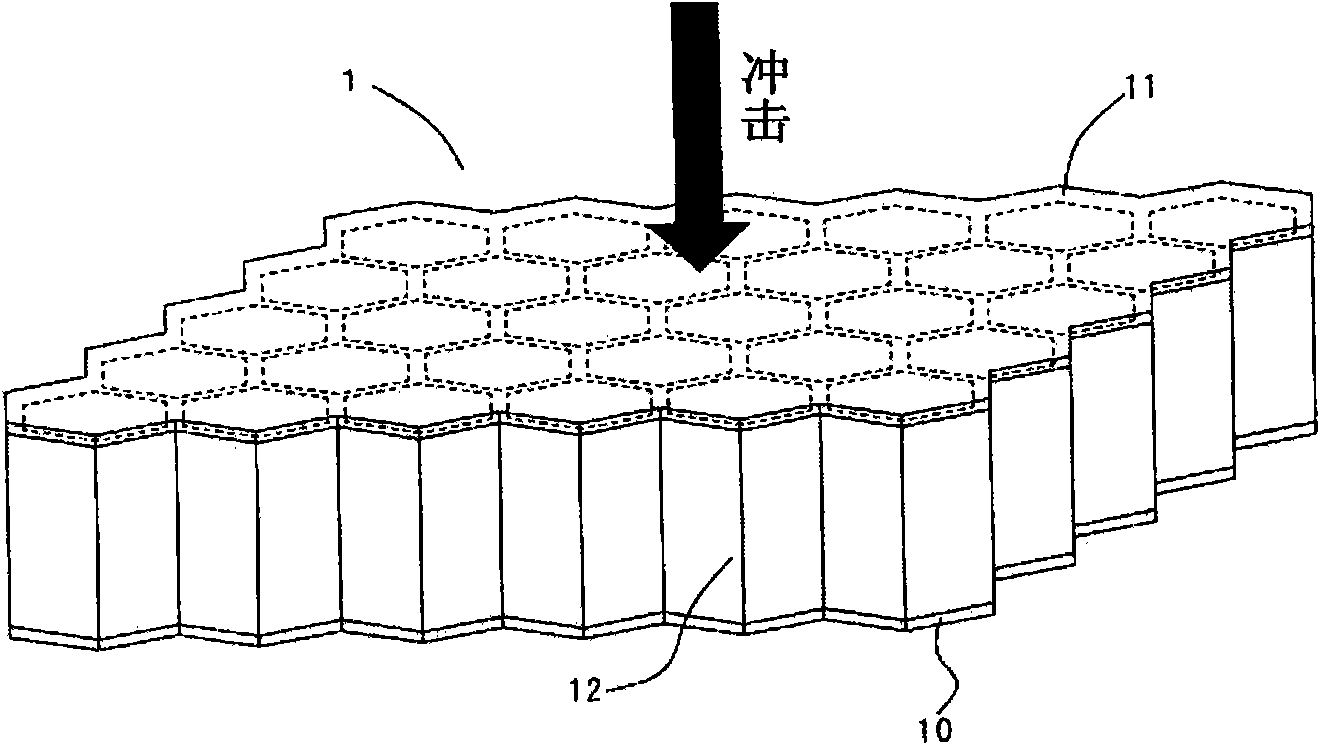

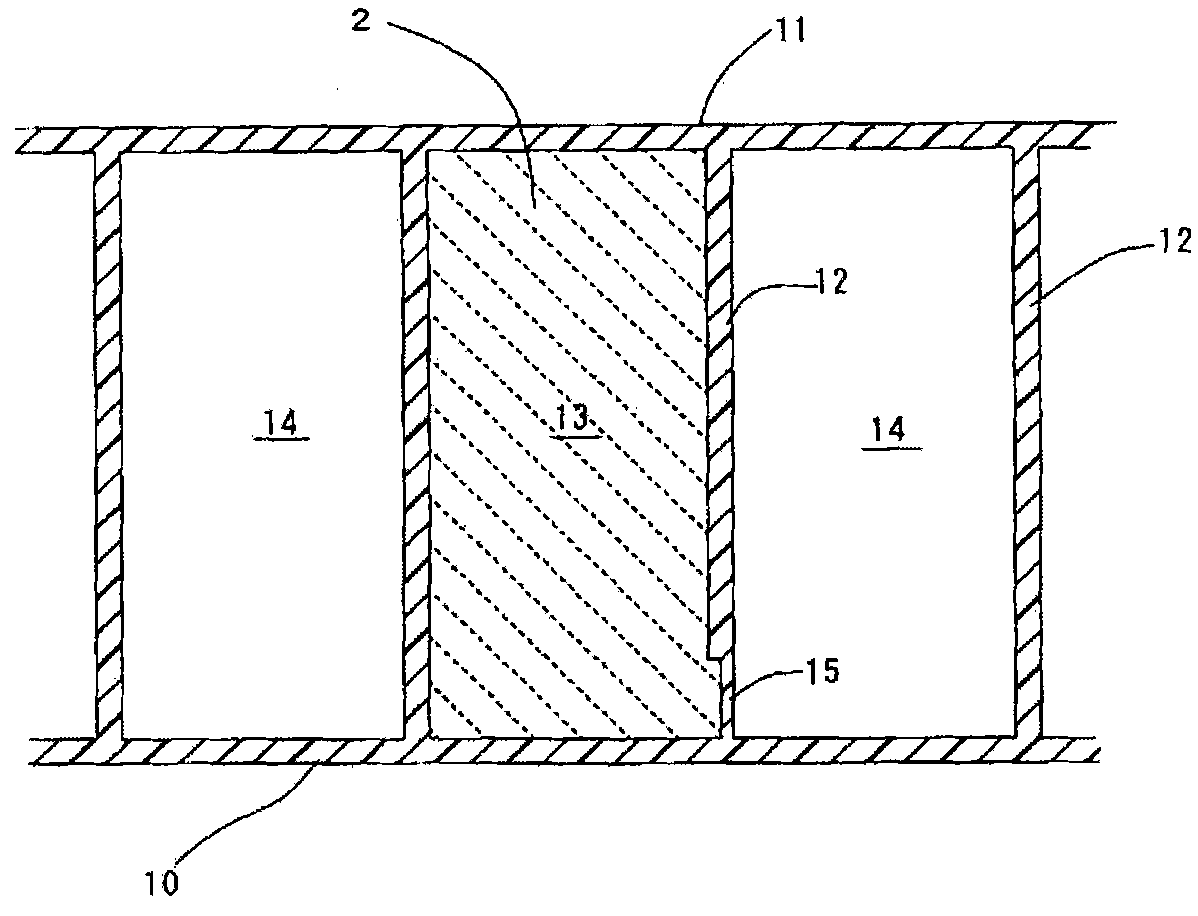

[0089] figure 1 The impact absorbing device of this embodiment is shown. This shock absorbing device 1 is composed of the following parts: the facing plate part 10; The space formed between the facing plate portion 10 and the pressure receiving plate portion 11 is divided into a plurality of small chambers. The cells formed by the facing plate portion 10 , the pressure receiving plate portion 11 , and the grid-like ribs 12 are each formed in a regular hexagonal cross-section, and are formed in a honeycomb shape as a whole.

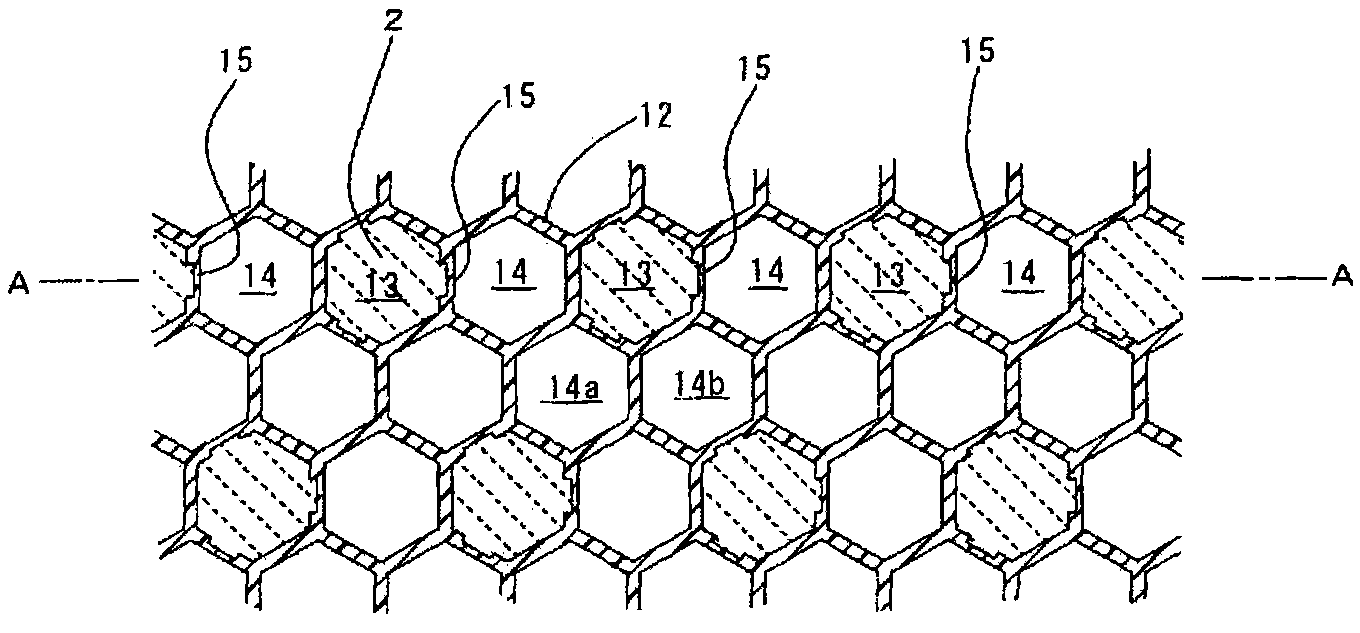

[0090] Sections of multiple compartments such as figure 2 As shown, it is composed of a filled cell 13 filled with the enclosure 2 and an empty cell 14 filled with nothing but air. Around the filled cell 13, the positions corresponding to the sides of the cross-sectional hexagon are respectively connected to the empty cells. The chambers 14 are adjacent. In addition, on the 3 ribs 12 that are separated from each other by one rib among the 6 ribs 12 th...

Embodiment 2

[0098] However, in the shock absorbing device 1 of Example 1, it may be difficult for the enclosure 2 that has flowed into the empty cell 14 from the broken thin portion 15 to flow out of the enclosure 2 . For example figure 2 The illustrated empty cell 14a allows the inflow of the enclosure 2 from the adjacent filled cell 13, but cannot flow out to the other adjacent empty cell 14b or the like. Therefore, when the colliding object M penetrates further and comes into contact with the enclosure 2 in the filled cell 13 and the empty cell 14 that are communicated with each other through the broken thin-walled portion 15, the enclosure 2 is compressed and may rebound. .

[0099] Therefore, the shock absorbing device of the present embodiment is as Figure 7 As shown, the second thin-walled portion 16 is formed on the rib portion 12 that divides the adjacent empty cells 14 . With the configuration as described above, the enclosed body 2 is dispersed into the plurality of empty ...

Embodiment 3

[0101] The impact absorbing device of the present embodiment is formed on the portion opposite to the empty cell 14 of the opposing plate portion 10 . Figure 9 Except for the second thin portion 16 shown, it has the same structure as that of the first embodiment.

[0102] According to the shock-absorbing device of this embodiment, when the thin-walled part 15 breaks and the empty cell 14 is filled with the enclosure 2 and then compressed, the second thin-walled part 16 breaks, and the enclosure 2 is moved from the breakage to the shock-absorbing device. External discharge. Therefore, the bottoming phenomenon caused by the enclosure 2 can be eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com