Backlight unit and liquid crystal display device

A technology for backlight units and liquid crystal display panels, applied in optical components, lighting devices, optics, etc., can solve the problems of easy warping of the mounting substrate 111 and inability to completely cope with heat dissipation of the heat sink, and improve the degree of freedom of configuration and the degree of freedom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

[0124] Embodiment 2 will be described. In addition, components having the same functions as those used in Embodiment 1 are given the same reference numerals and their descriptions are omitted.

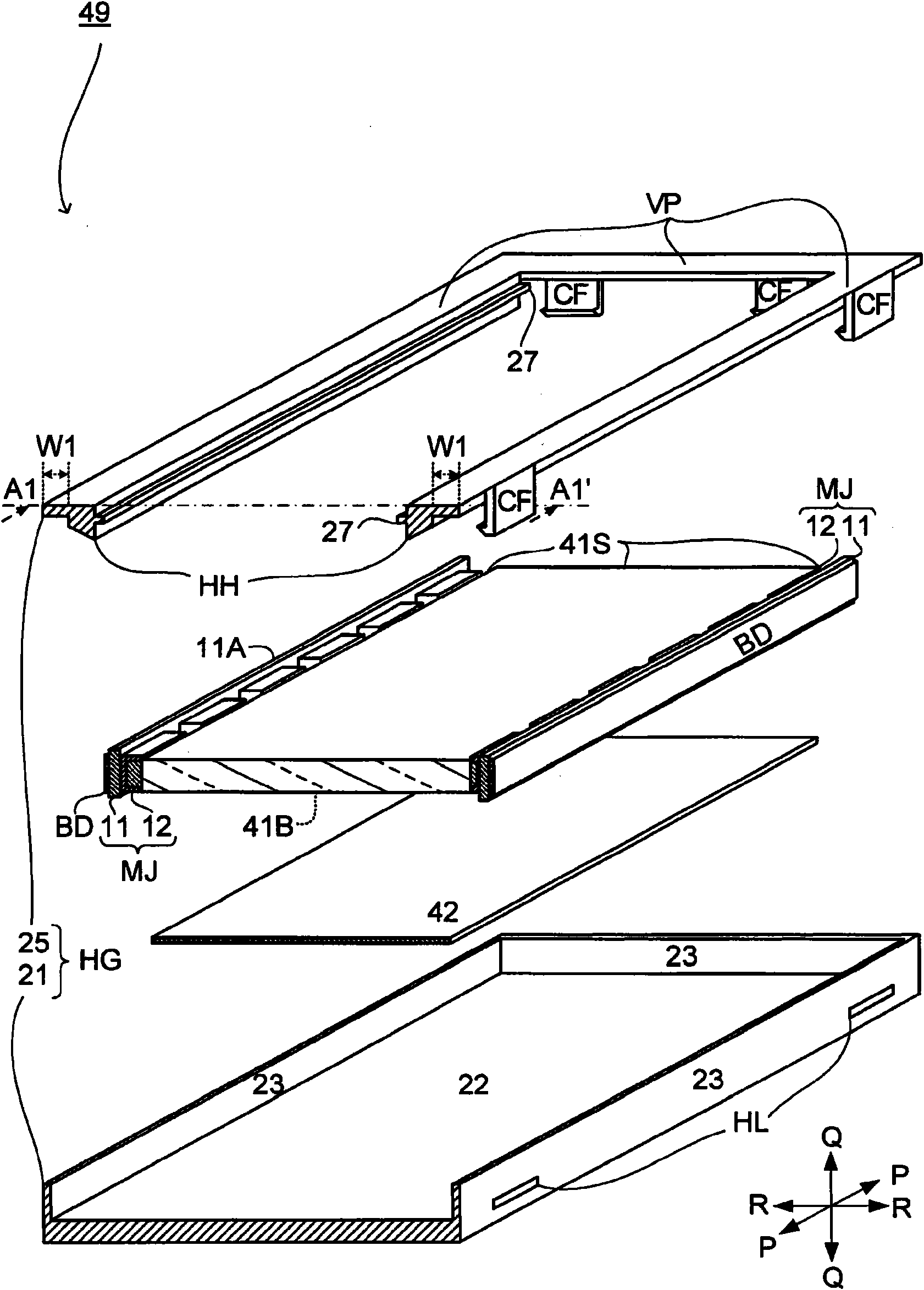

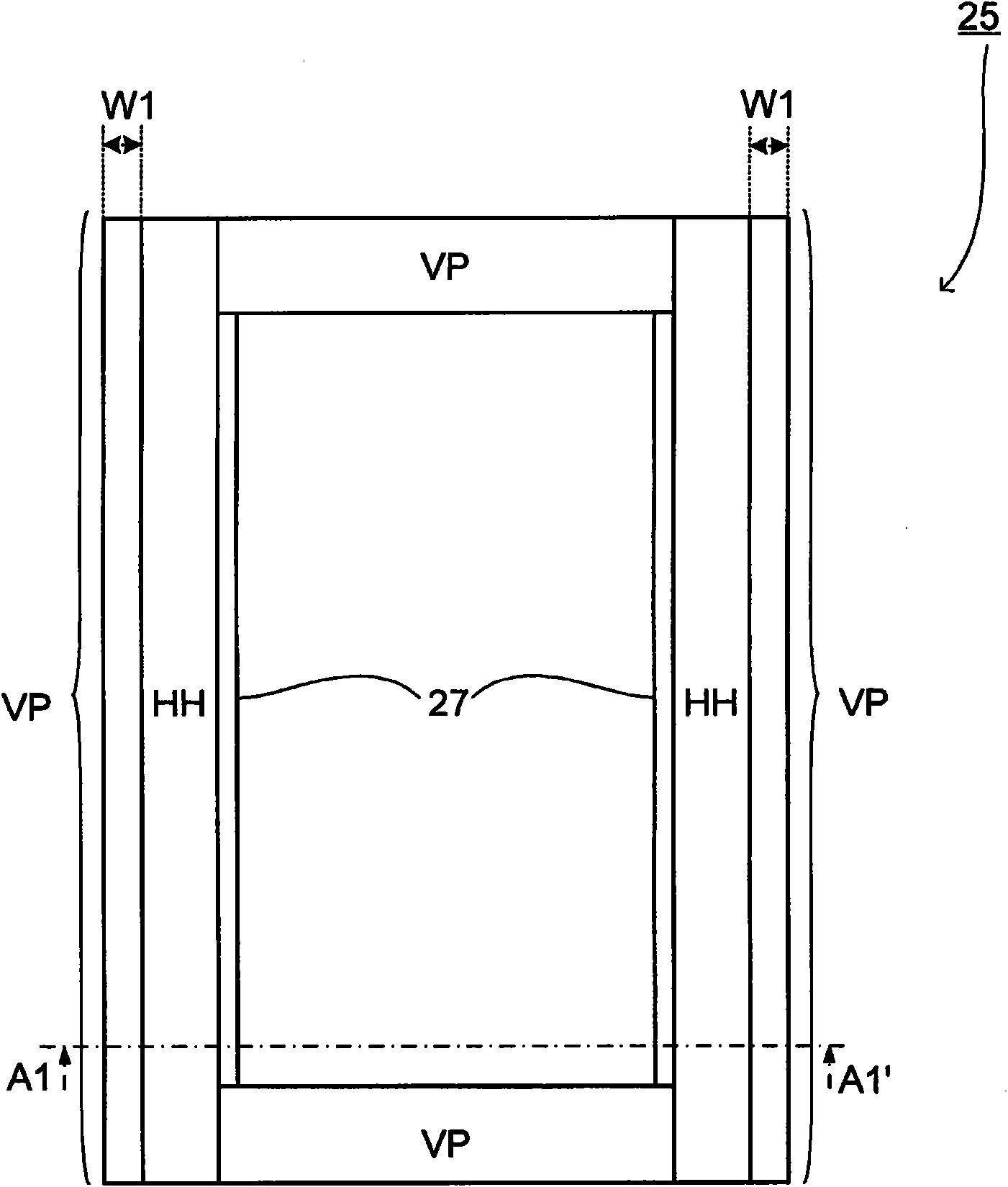

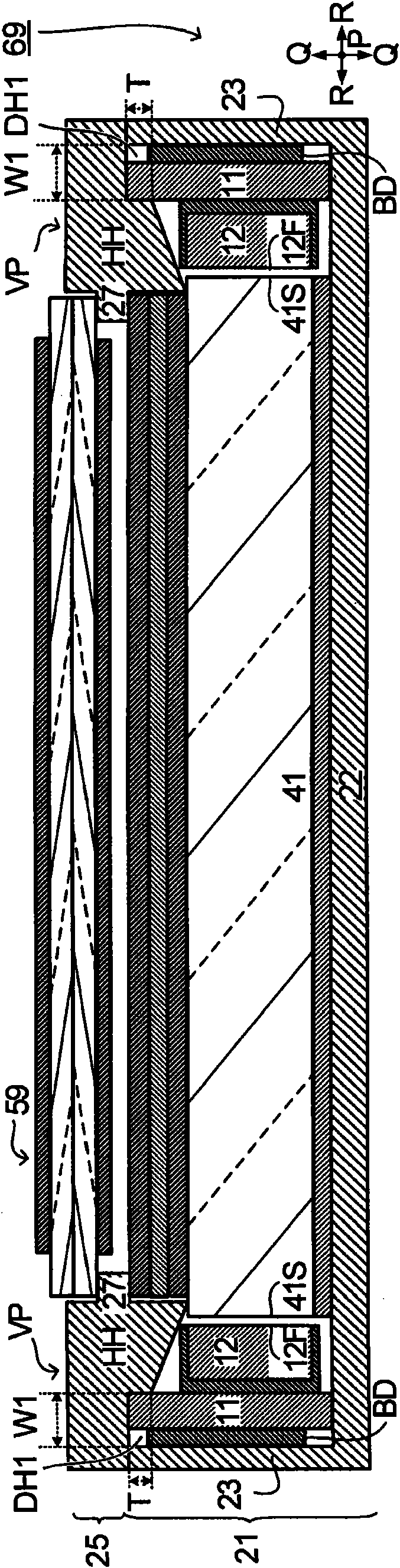

[0125] In the backlight unit 49 described in Embodiment 1, the mounting substrate 11 is sandwiched by the first groove DH1 defined by the side VP of the top-shaped housing 25 and the wall of the bottom-shaped housing 21 . 23 formed. In this embodiment 2, with Figure 11 and Figure 12 A case where the mounting substrate 11 is sandwiched by the second grooves (second grooves) DH2 other than the first groove DH1 will be described.

[0126] also, Figure 11 become with figure 1 in the same manner, Figure 12 become with image 3 in the same manner (in addition, Figure 12 The direction of the section is Figure 11 The direction indicated by the arrow at line A4-A4' of the

[0127] as it should Figure 11 and Figure 12 As shown, the second groove DH2 includes, as a part, a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com