Lithium secondary battery and manufacturing method for same

A lithium secondary battery and electrode technology, applied in the field of lithium secondary battery and its manufacturing, can solve the problems of poor high-speed discharge characteristics, excessive temperature rise, long current flow distance, etc., to improve reliability, shorten current flow distance, Effect of improving high-speed discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] The present invention will be described in more detail below with reference to the accompanying drawings.

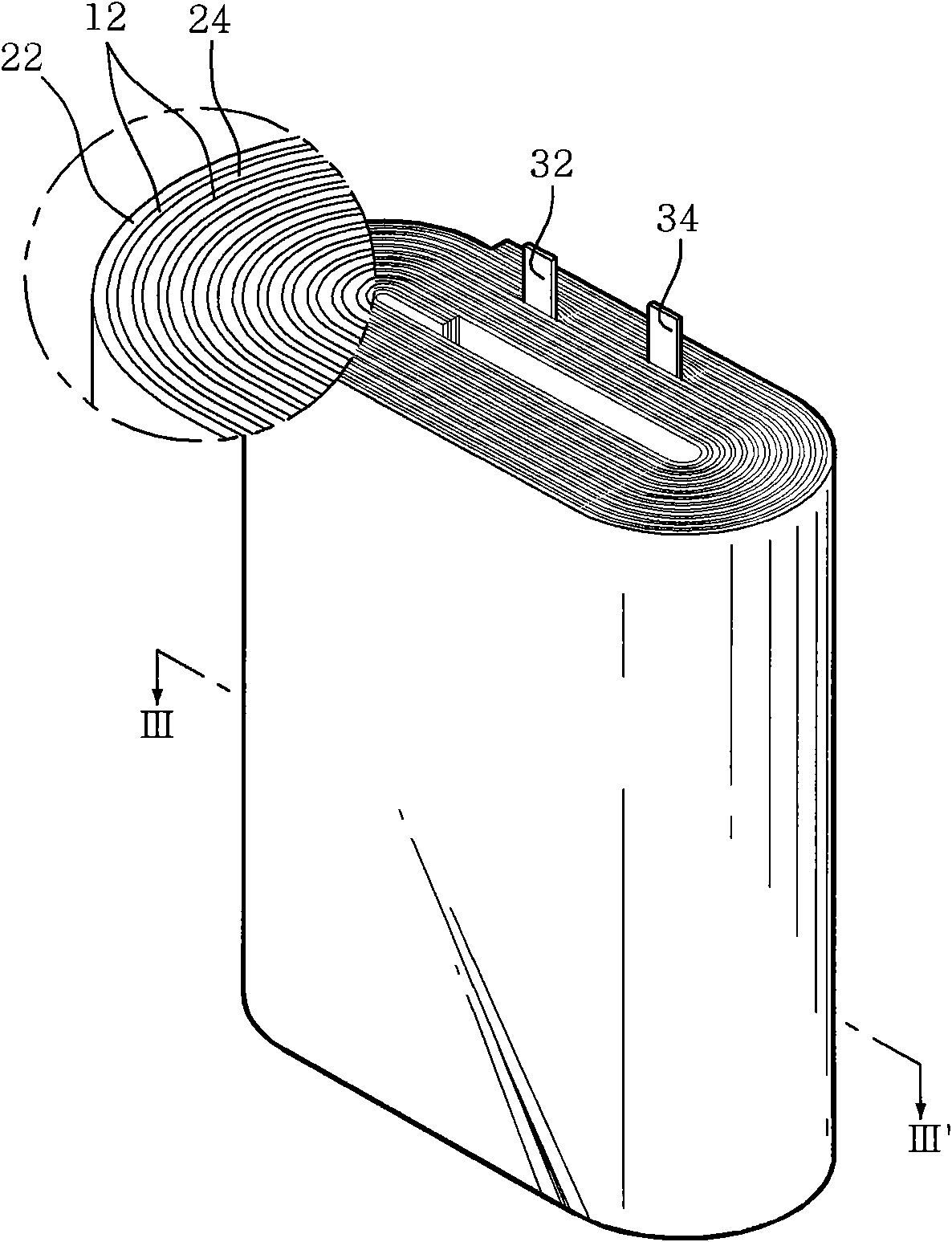

[0047] figure 1 is a perspective view showing a lithium secondary battery according to an embodiment of the present invention.

[0048] refer to figure 1 , a lithium secondary battery according to an embodiment of the present invention includes: a first electrode 22 (hereinafter referred to as "cathode") and a second electrode 24 (hereinafter referred to as "anode"), which are provided with a separator 12 therebetween is wound; an electrode group comprising a first electrode sheet 32 connected to the cathode 22 (hereinafter referred to as "cathode sheet") and a second electrode sheet 34 connected to the anode 24 (hereinafter referred to as "anode sheet"); and containing The casing of the electrode group (not shown in the figure).

[0049]Depending on the type of lithium secondary battery, a liquid electrolyte may be filled in the case, or the separator 12 may...

Embodiment

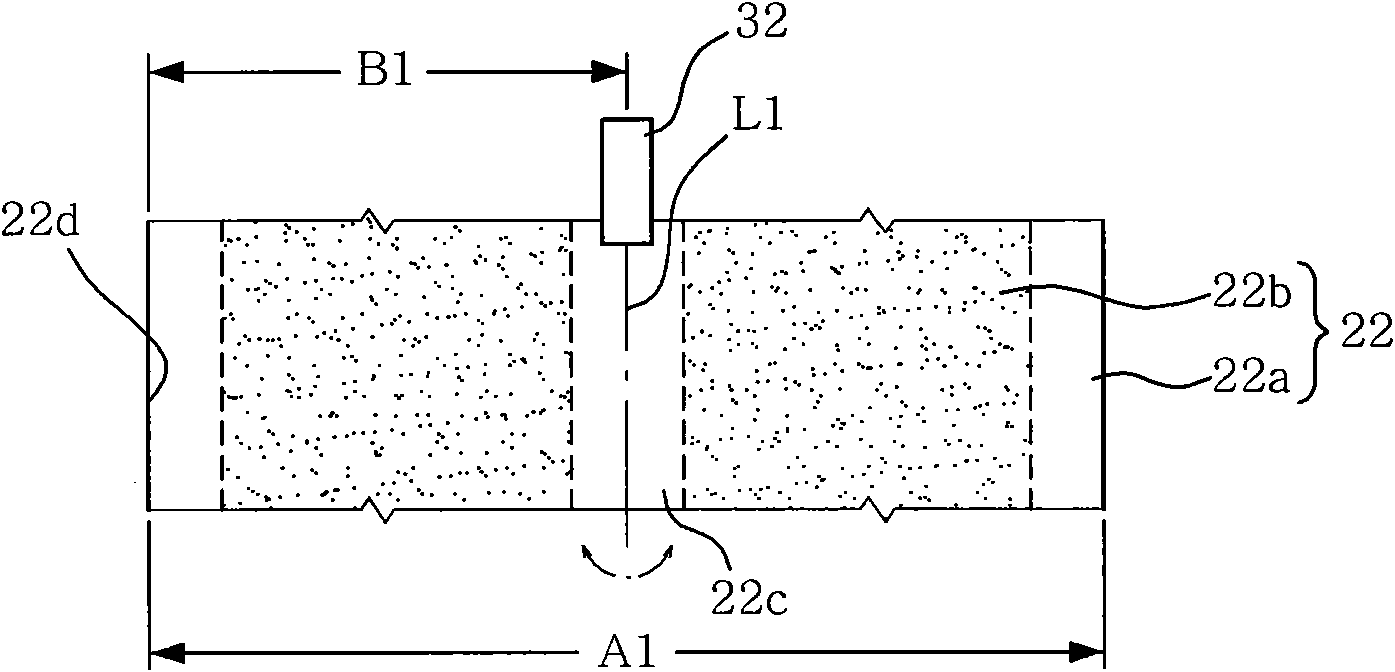

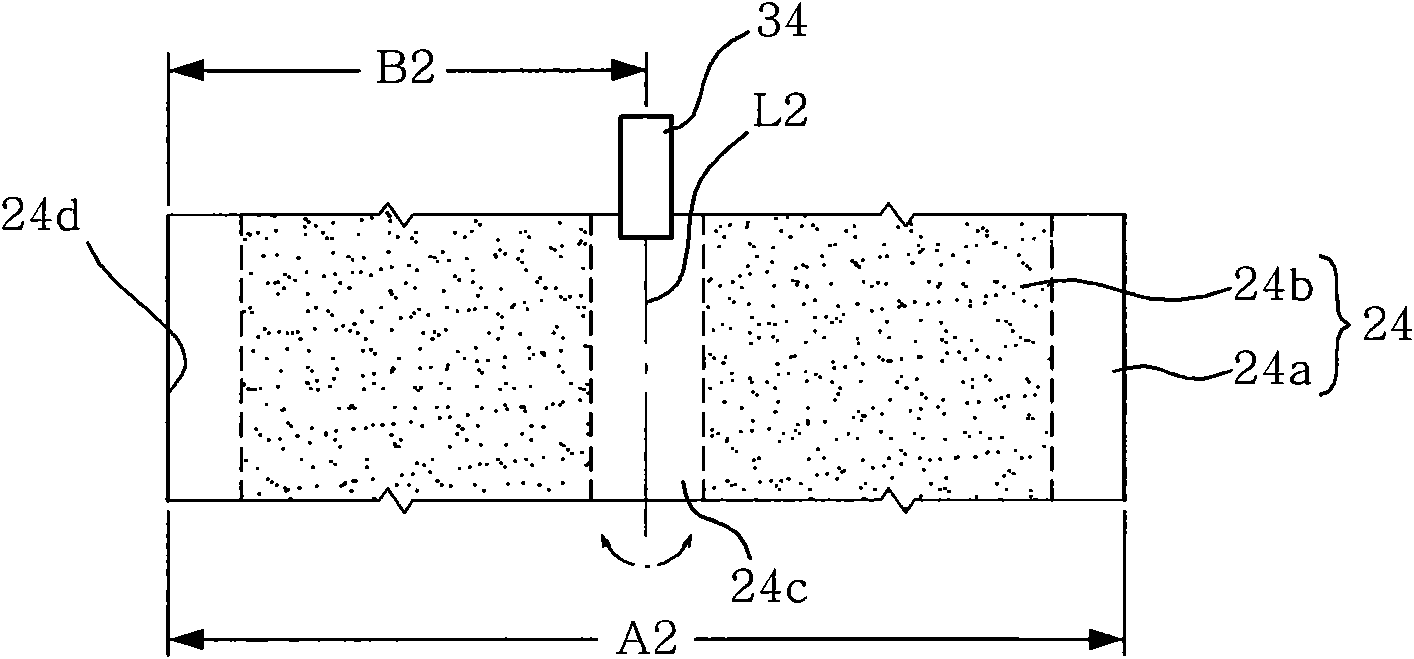

[0098] LiCoO as the cathode active material 2 , polyvinylidene fluoride (PVDF) as a binder, and carbon black as a conductive material were mixed to form a mixture, and then N-methylpyrrolidone (NMP) was added to the mixture to prepare a slurry.

[0099] The slurry was applied at intervals to one side of the cathode current collector body made of aluminum foil, and then applied at intervals to the other side of the cathode current collector body to form a plurality of cathode active material patterns. A cathode current collector body including a plurality of cathode active material patterns formed on both sides thereof was dried until N-methylpyrrolidone (NMP) was completely volatilized, and then rolled.

[0100] The rolled cathode current collector body was cut to form a cathode including two cathode active material patterns, and a cathode central uncoated portion formed between the two cathode active material patterns.

[0101] A cathode tab made of aluminum was connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com