Oxygen-permeable film, oxygen-permeable sheet and electric cell comprising the same

A permeable membrane and air battery technology, which is applied in the field of membranes that inhibit the penetration of water vapor and air purification membranes, can solve the problems of radio communication quality degradation, lower electric field strength, etc., achieve good high-speed discharge characteristics, inhibit water clogging, expand The effect of the permissible operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Oxygen permeable sheet A1~A15

[0093] Oxygen permeable membranes including water-repellent particles (average particle diameter: 0.009 μm to 70 μm) shown in Table 1A were formed on porous substrates having different Gurley numbers by the above-mentioned predetermined film formation method.

[0094] (i) Make A1

[0095] A porous membrane having a Gurley number of 500 seconds and including polytetrafluoroethylene (manufactured by Japan Gore-Tex Inc.: product number GF52) was used as the porous substrate. Particles (particles A1) including polytetrafluoroethylene having an average particle diameter of 70 μm were used as water-repellent particles. An oxygen permeable sheet was produced by film formation method 1 (spray coating method). Spray the contents of the spray can onto the porous substrate from a distance of approximately 30 cm from the porous substrate for 2 seconds.

[0096] The contents filled into the spray tank had a composition comprising 40% by weight of n...

Embodiment 2

[0124] Fabrication of Oxygen Permeable Sheets B1~B7

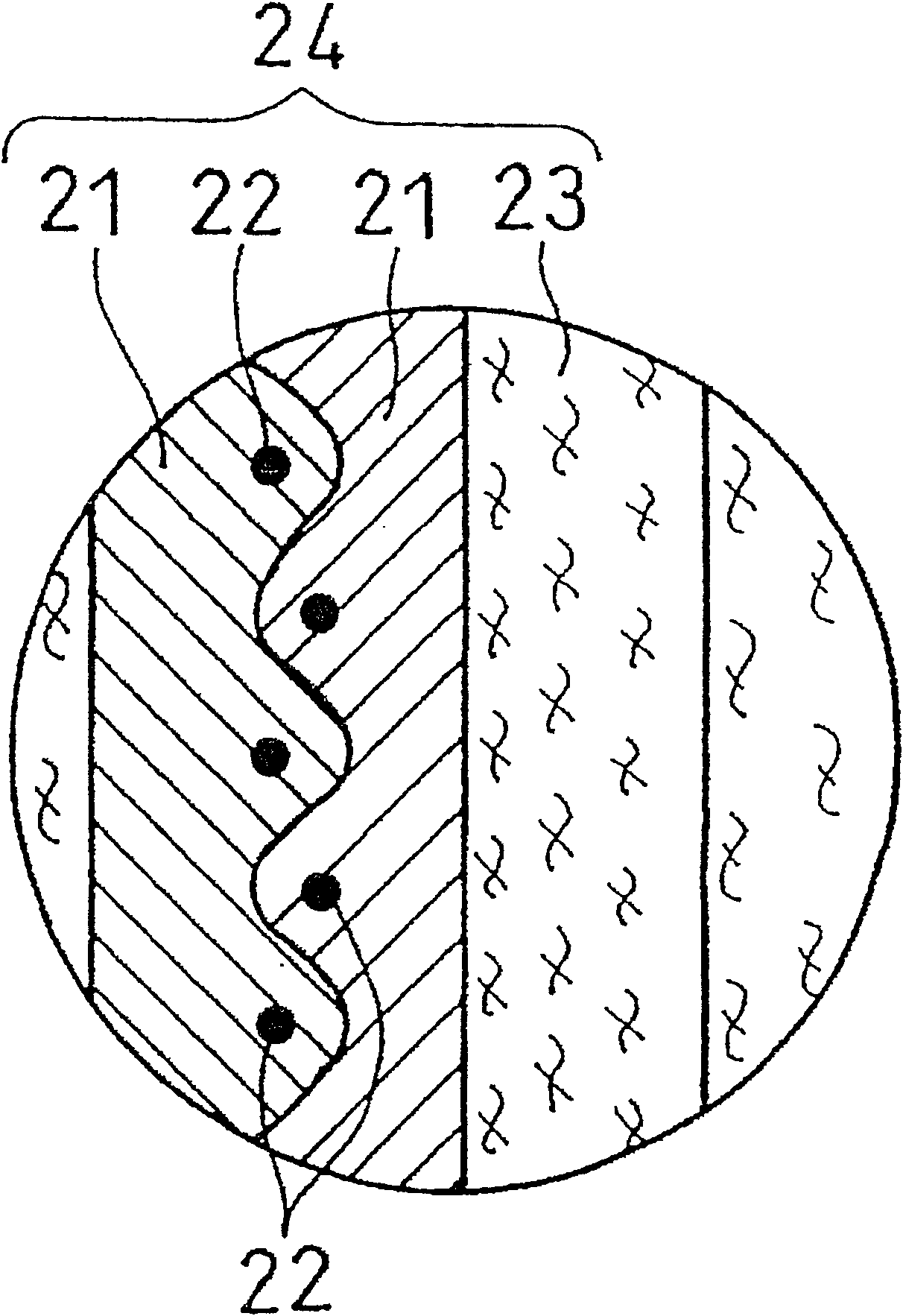

[0125] According to the procedure used for the oxygen permeable sheet A1, a coating was formed by film-forming method 1 (spray coating method) using the water-repellent particles listed in Table 1B, followed by annealing in the atmosphere for about 10 minutes. Thus, oxygen permeable sheets B1 to B7 having oxygen permeable membranes in which particles in point contact with each other are fused together are obtained. By fusing the point-contact particles together in this way, the durability of the effect of suppressing the transmission of water vapor is increased, thereby improving the oxygen permeability. However, when the particles are melted excessively, there will be no unevenness on the surface of the film including particle aggregates and the inner walls of pores in the film, thereby degrading the waterproofness of the film.

[0126]When polytetrafluoroethylene is used as the water repellent particles, the annealing te...

Embodiment 3

[0136] Making Oxygen Permeable Sheets C1~C7

[0137] Oxygen permeable sheets C1 to C7 were fabricated by film-forming method 1 (spray coating method) using the water-repellent particles listed in Table 1B according to the procedure used for oxygen permeable sheet A1.

[0138] It should be noted that the weight ratio of the water repellent particles in C5 was set to be polytetrafluoroethylene: vinyl fluoride = 80: 20, and the weight ratio of water repellent particles in C6 was set to be polytetrafluoroethylene: vinyl fluoride: vinylidene fluoride = 80:10:10.

[0139] The underlying porous membrane was used as a porous substrate.

[0140] C1: Porous membrane including polytetrafluoroethylene

[0141] C2: porous membrane including polyethylene

[0142] C3: Porous membrane including polypropylene

[0143] C4: Porous membrane including vinylon

[0144] C5: Porous film including polyphenylene sulfide

[0145] C6: Porous film including polybutylene terephthalate

[0146] C7: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com