Aqeuous electrolyte composition and sealed-type primary film battery including electrolyte layer formed of the aqueous electrolyte composition

A technology of aqueous electrolyte and electrolyte layer, applied in the direction of non-aqueous electrolyte batteries, batteries with solid electrolytes, aqueous electrolytes, etc., can solve the problems of battery deterioration and failure to work, and achieve the prevention of battery performance deterioration, excellent ion conductivity, Effect of improving high-speed discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

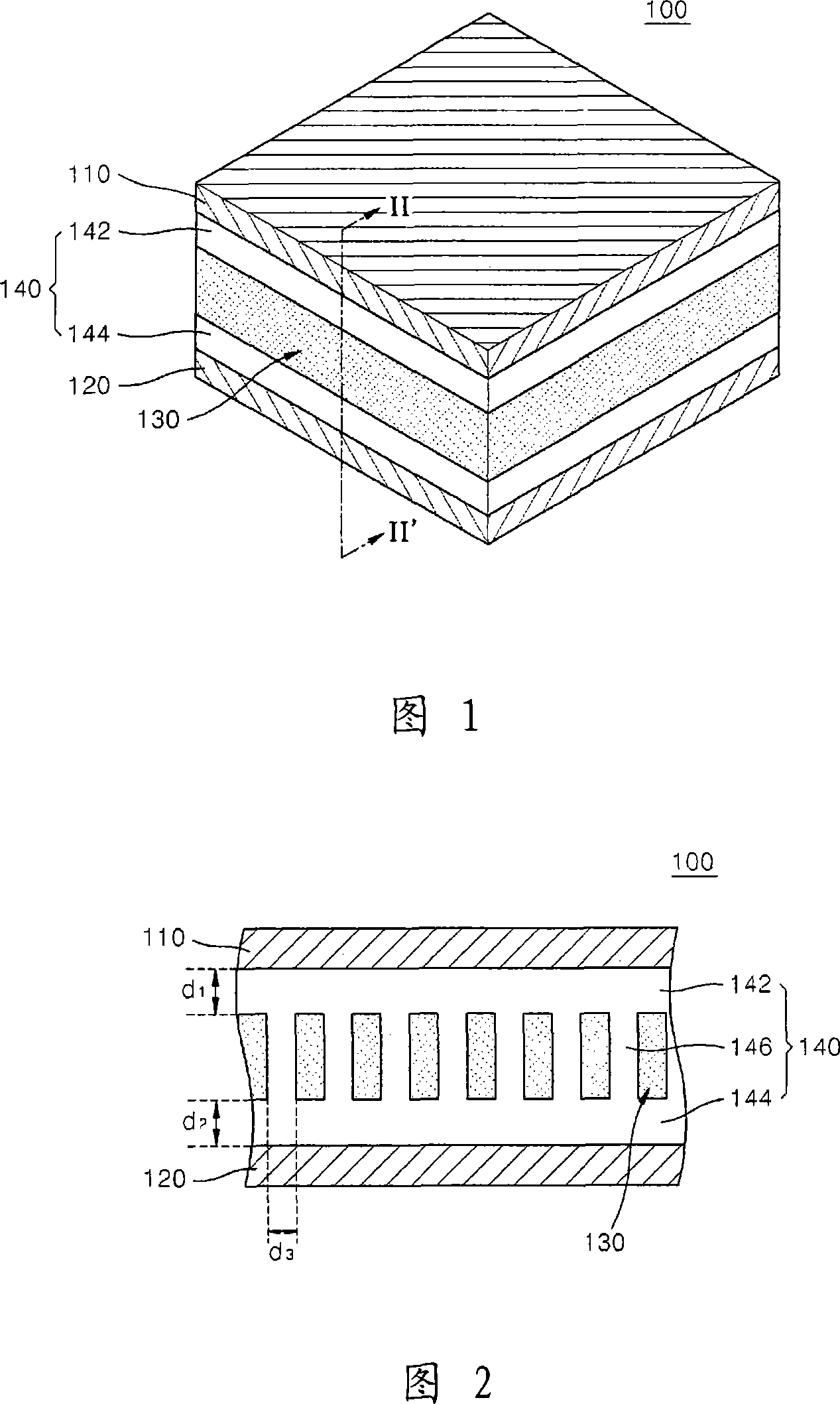

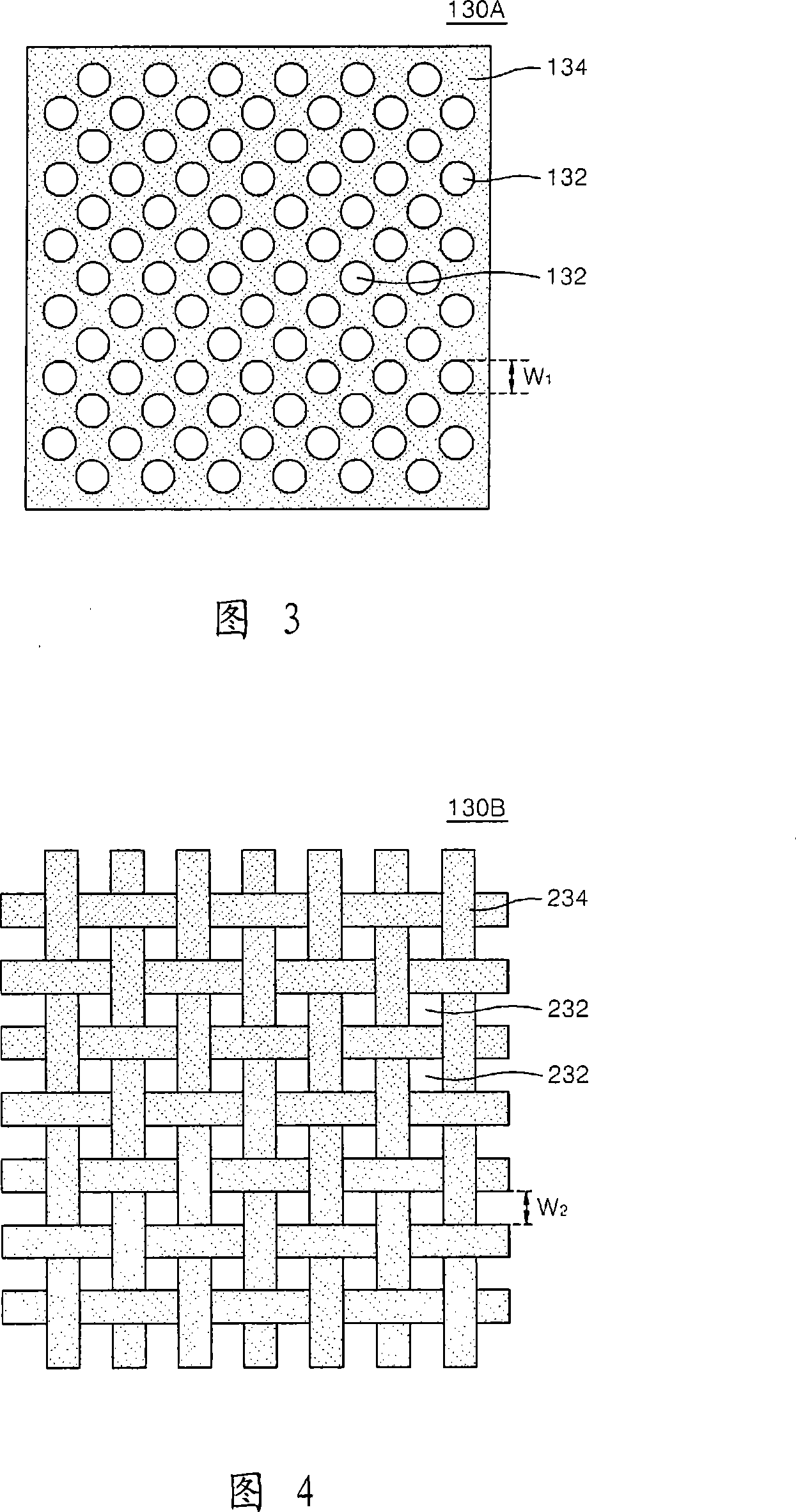

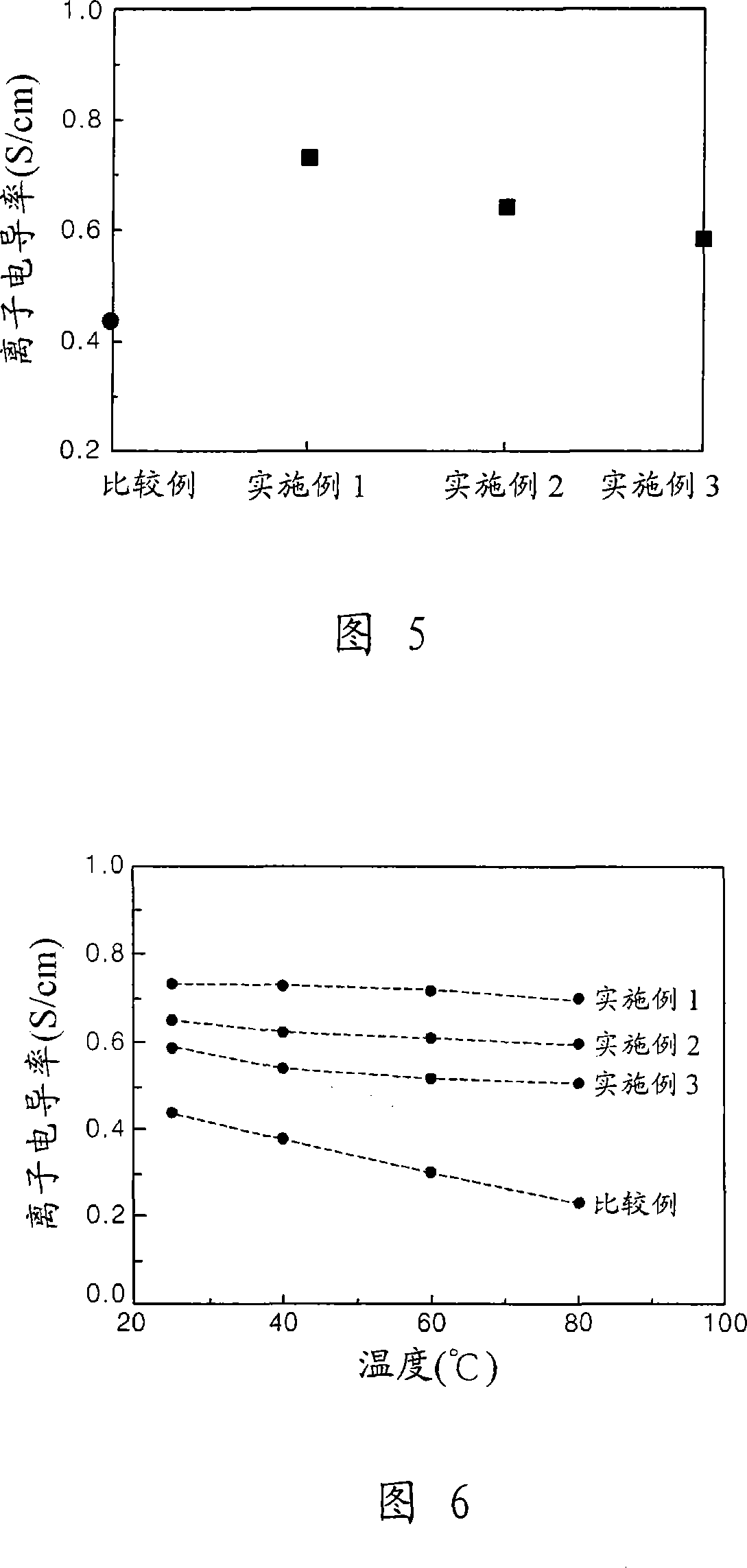

[0044] A porous polyethylene (PE) film having a thickness of 20 μm was prepared. A plurality of circular through-holes having a diameter of 500 μm were then formed in the porous PE film using a puncher to prepare a separator.

[0045] To prepare the aqueous electrolyte composition, 5% by weight of hydrophilic particulate polyethyleneimine was added to a 6M potassium hydroxide (KOH) solution, and 10% by weight of polyacrylic acid and carboxymethylcellulose (weight ratio 1:1) of the polymer blend was added thereto to prepare a very waxy (very waxy) electrolyte gel. Electrolyte gel is coated on both surfaces of the separator to form an electrolyte layer. At this time, the electrolyte gel coated on the surface of the separator flows in and completely fills the through holes formed in the separator.

[0046] A positive electrode film and a negative electrode film were laminated and hermetically adhered on both surfaces of the resulting structure including the separator and the el...

Embodiment 2

[0048] Except using the polymer blend of polyethylene oxide and polyvinyl alcohol (weight ratio 1:1) instead of the polymer blend of polyacrylic acid and carboxymethyl cellulose, adopt the same method as Example 1 Manufactures sealed primary membrane batteries.

Embodiment 3

[0050] In addition to using woven glass fibers with a thickness of 100 μm as the separator, and using 6M ammonium chloride (NH 4 Cl) solution was used instead of 6M KOH solution to prepare an aqueous electrolyte composition, and the same method as in Example 1 was used to manufacture a sealed primary membrane battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com