Electrochemical apparatus, isolation membrane used therein and preparation method of the isolation membrane

An electrochemical and isolation film technology, applied in the field of electrochemistry, can solve the problems of thinning of the coating and affect the performance of the isolation film, so as to achieve increased coating thickness, excellent air permeability and ion conductivity, and reduce the risk of uneven thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

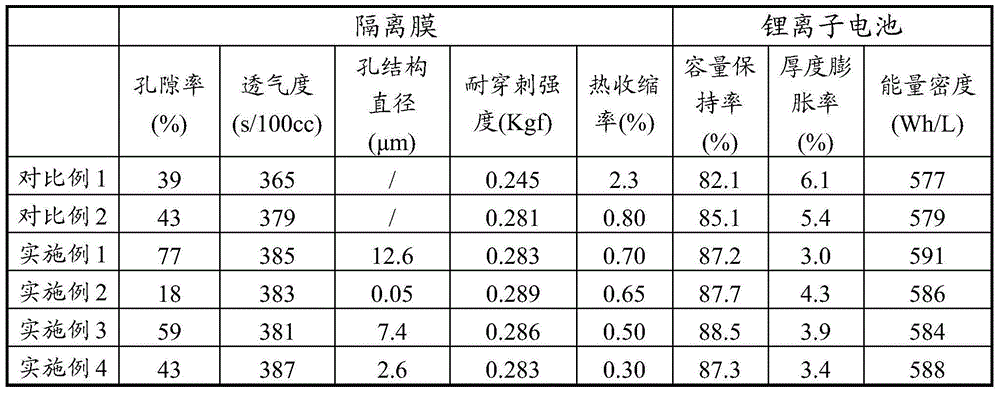

Examples

Embodiment 1

[0051] The process of positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell forming is the same as that of Comparative Example 1, but the separator is prepared by the following method:

[0052] Add 40 parts by mass of sodium silicate solution (the mass fraction is 50%, the solvent is water) and 17 parts by mass of lithium chloride into a double planetary mixer, and stir at room temperature for 60 minutes; then add 0.016 parts by mass of pure acrylic acid The emulsion and 10 parts by mass of deionized water were mixed at room temperature for 1 hour to obtain an inorganic salt solution slurry;

[0053] The polypropylene porous substrate is coated on both sides by transfer coating, and the coating speed is 40m / min;

[0054] It is dried in a three-stage oven (each section is 3 meters long, and the temperature of each section is 40°C, 42°C, and 40°C respectively). After drying, the thickness of one side of the obtained coating is measured to be 0.1 μ...

Embodiment 2

[0056] The process of positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell forming is the same as that of Comparative Example 1, but the separator is prepared by the following method:

[0057] Add 24 parts by mass of potassium silicate solution (20% by mass, water as the solvent) and 0.72 parts by mass of methanol into a double planetary mixer, and stir at room temperature for 60 minutes; then add 1.25 parts by mass of neopentyl glycol Diacrylate and 13 parts by mass of deionized water were mixed at room temperature for 1 hour to obtain an inorganic salt solution slurry;

[0058] The polypropylene / polyethylene / polypropylene three-layer composite porous substrate is coated on both sides by screen printing, and the coating speed is 2m / min;

[0059] It is dried in a three-stage oven (each section is 3 meters long, and the temperature of each section is 90°C, 100°C, and 90°C respectively). After drying, the thickness of the coating on one side is m...

Embodiment 3

[0061] The process of positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell forming is the same as that of Comparative Example 1, but the separator is prepared by the following method:

[0062] Add 30 parts by mass of ammonium aluminum carbonate solution (mass fraction is 80%, solvent is water) and 15 parts by mass of polyvinyl alcohol into a double planetary mixer, stir at room temperature for 60min; then add 2.9 parts by mass of epoxy Resin and 9 parts by mass of deionized water were mixed at room temperature for 1 hour to obtain an inorganic salt solution slurry;

[0063] The polypropylene / polyethylene / polypropylene three-layer composite porous substrate is coated on both sides by extrusion coating, and the coating speed is 15m / min;

[0064] It was dried in a three-stage oven (the length of each section is 3 meters, and the temperature of each section is 62°C, 70°C, and 64°C). After drying, the thickness of one side of the coating was measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com