An all-solid-state lithium battery and a preparation method thereof

A lithium battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor cycle stability, inability to effectively control the electrode structure, low battery energy density, etc., to achieve poor electronic conductivity, Good ion conductivity, the effect of weakening the formation of space charge layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

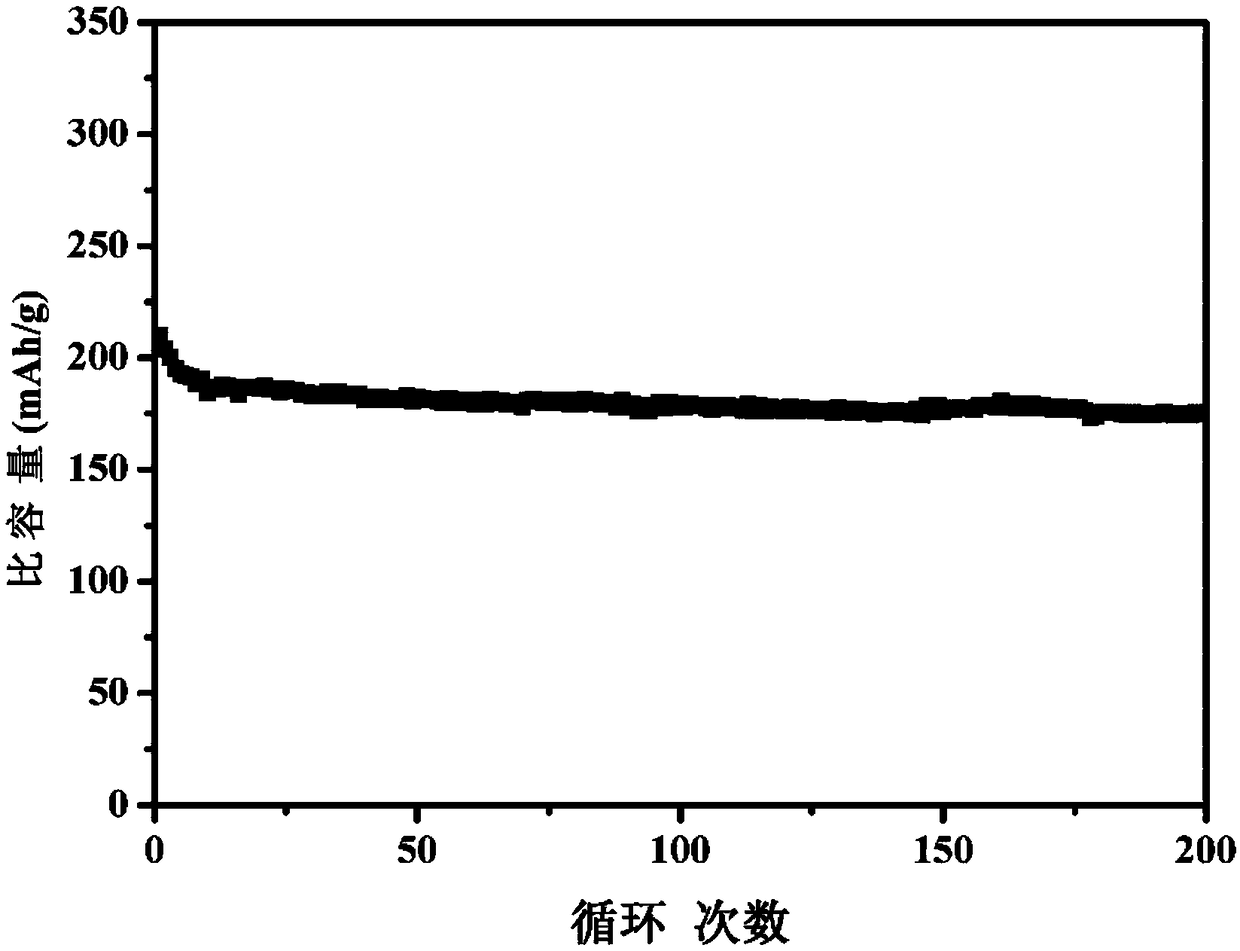

[0036] Choose LiNi 0.8 co 0.1 mn 0.1 o 2 As a positive electrode material coated into a pole piece, garnet-type Li 7 La 3 Zr 2 o 12 As the electrolyte, it is pressed into a 13mm sheet, and metal lithium is used as the negative electrode. Weigh 30 g of melamine in a crucible, raise the temperature to 550° C., and keep it warm for 6 hours to obtain a yellow powder. Then weigh 5g yellow powder and 2g NaNO 3 To mix, add 120 mL concentrated H 2 SO 4 Place in an ice bath and stir. Add 10g KMnO after reacting for 40min 4 , and then moved into a warm water bath at 40°C to continue the reaction. After 30 minutes, deionized water was slowly added, and the reaction temperature was kept at 98°C. After stirring for 5 minutes, an appropriate amount of H was added. 2 o 2 Filter until no bubbles are generated, wash the filter residue until it is neutral, then dry it, and then ultrasonically disperse it in DMF. The dispersion liquid was added dropwise on the solid electrolyte lay...

Embodiment 2

[0039] Choose LiCoO 2 As a positive electrode material coated into a pole piece, garnet-type Li 7 La 3 Zr 2 o 12 As the electrolyte, it is pressed into a 13mm sheet, and metal lithium is used as the negative electrode. Weigh 50 g of dicyandiamide into a crucible, heat up to 550° C., and keep it warm for 12 hours to obtain a yellow powder. Then weigh 3g yellow powder and 2g NaNO 3 To mix, add 180 mL concentrated H 2 SO 4 Place in an ice bath and stir. Add 10g KMnO after reacting for 40min 4 , and then moved into a warm water bath at 40°C to continue the reaction. After 20 minutes, deionized water was slowly added, and the reaction temperature was kept at 90°C. After stirring for 8 minutes, an appropriate amount of H was added. 2 o 2 Filter until no bubbles are generated, wash the filter residue until it is neutral, then dry it, and then ultrasonically disperse it in DMF. The dispersion liquid was added dropwise on the positive electrode, spin-coated and dried, and th...

Embodiment 3

[0042] Choose LiFeO 4 As the positive electrode material coated into pole pieces, sulfide Li 2 S-P 2 S 5 As the electrolyte, it is pressed into a 13mm sheet, and metal lithium is used as the negative electrode. Weigh 80 g of dicyandiamide into a crucible, heat up to 550° C., and keep it warm for 2 hours to obtain a yellow powder. Then weigh 6g yellow powder and 2g NaNO 3 To mix, add 120 mL concentrated H 2 SO 4 Place in an ice bath and stir. Add 10g KMnO after reacting for 40min 4 , and then moved into a warm water bath at 40°C to continue the reaction. After 60 minutes, deionized water was slowly added, and the reaction temperature was kept at 98°C. After stirring for 5 minutes, an appropriate amount of H was added. 2 o 2 Filter until no air bubbles are generated, wash the filter residue until it is neutral, then dry it, and then ultrasonically disperse it in NMP. The dispersion liquid was added dropwise on the solid electrolyte layer, spin-coated and dried, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com