Electric tool

A technology of electric tools and electric current, which is applied in the direction of motor tools, manufacturing tools, wrench, etc., can solve the problems of drilling operation confusion, can not clearly understand whether the electronic clutch will work, etc., to prolong life, avoid overload, operate Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

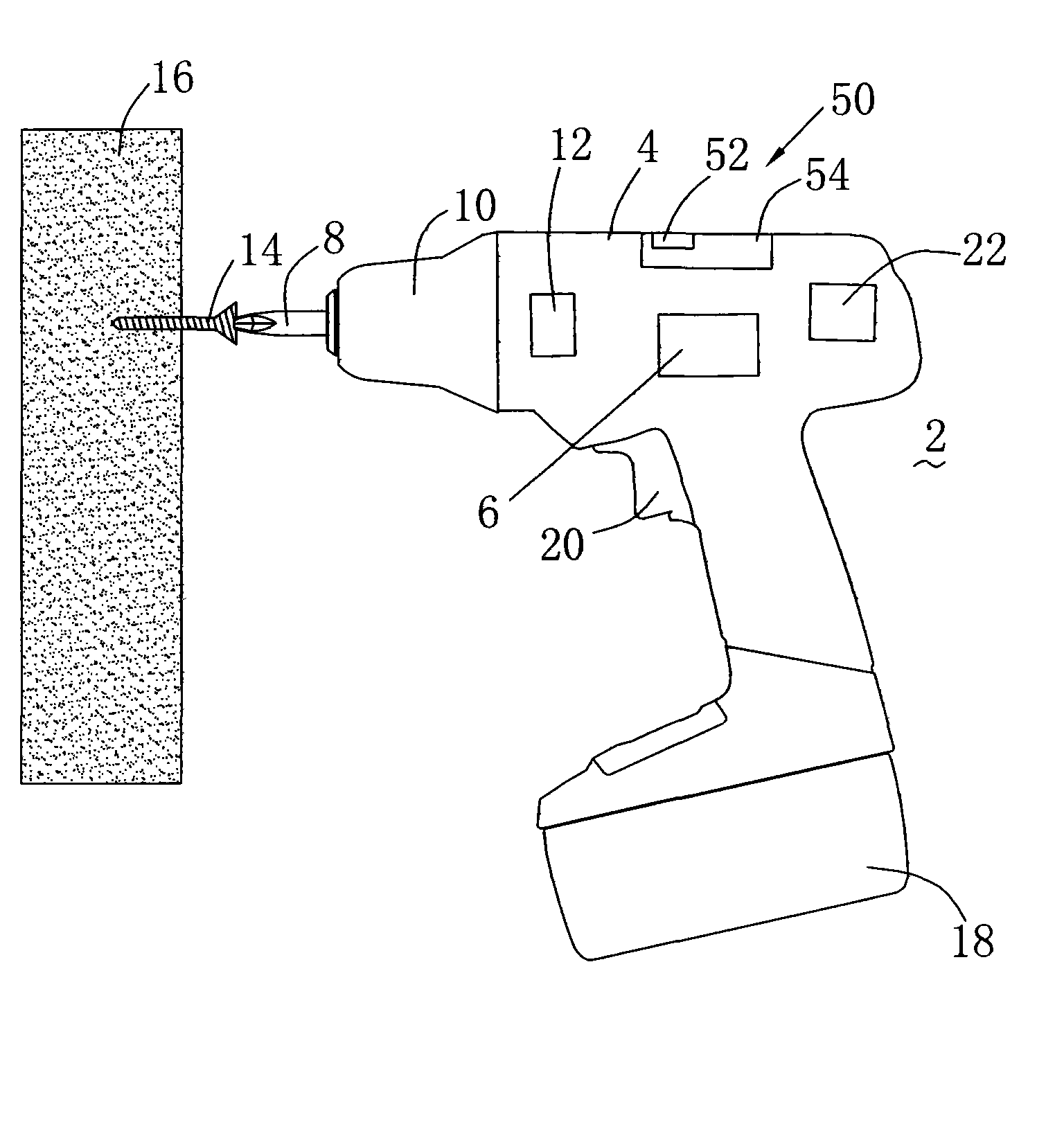

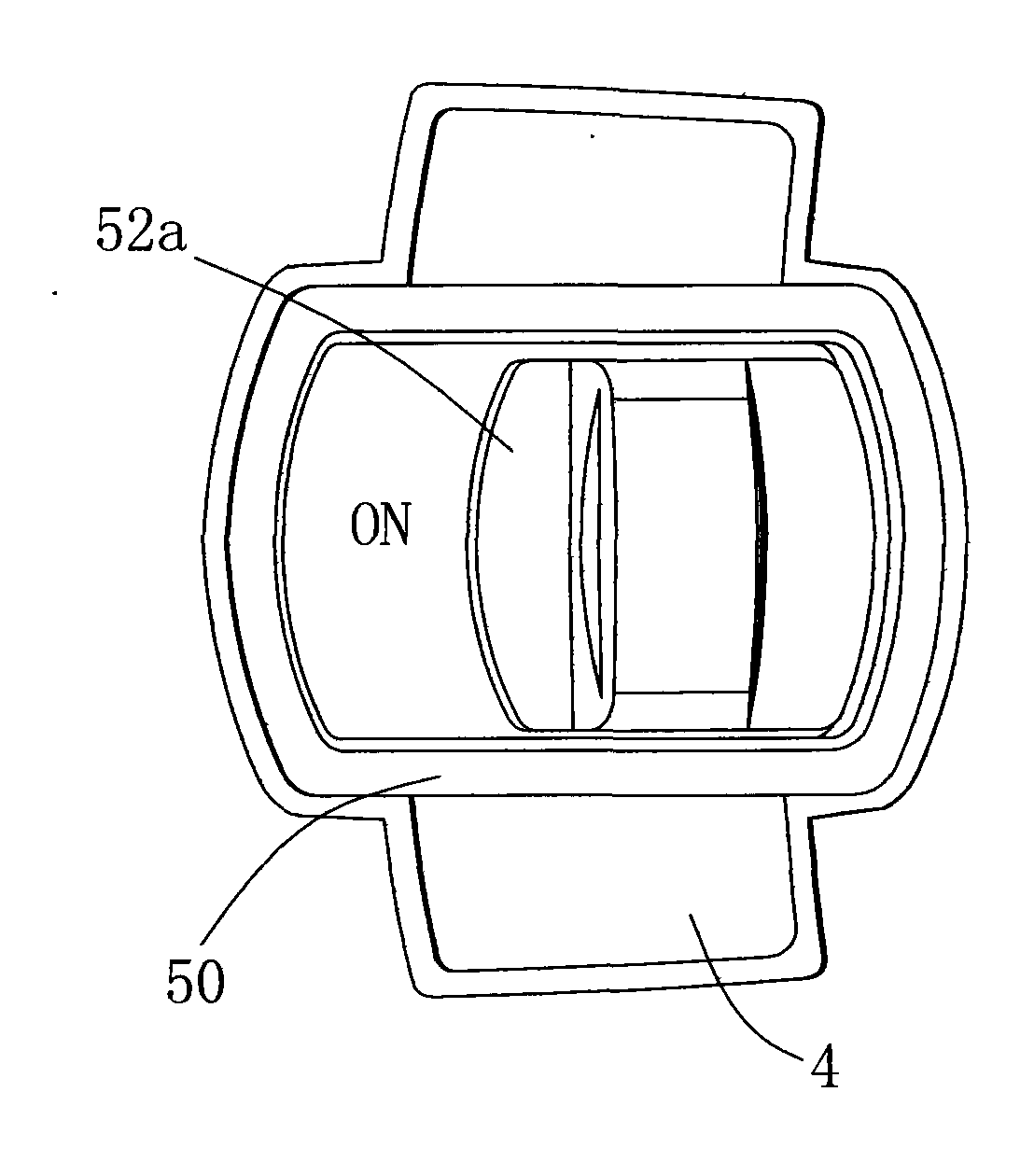

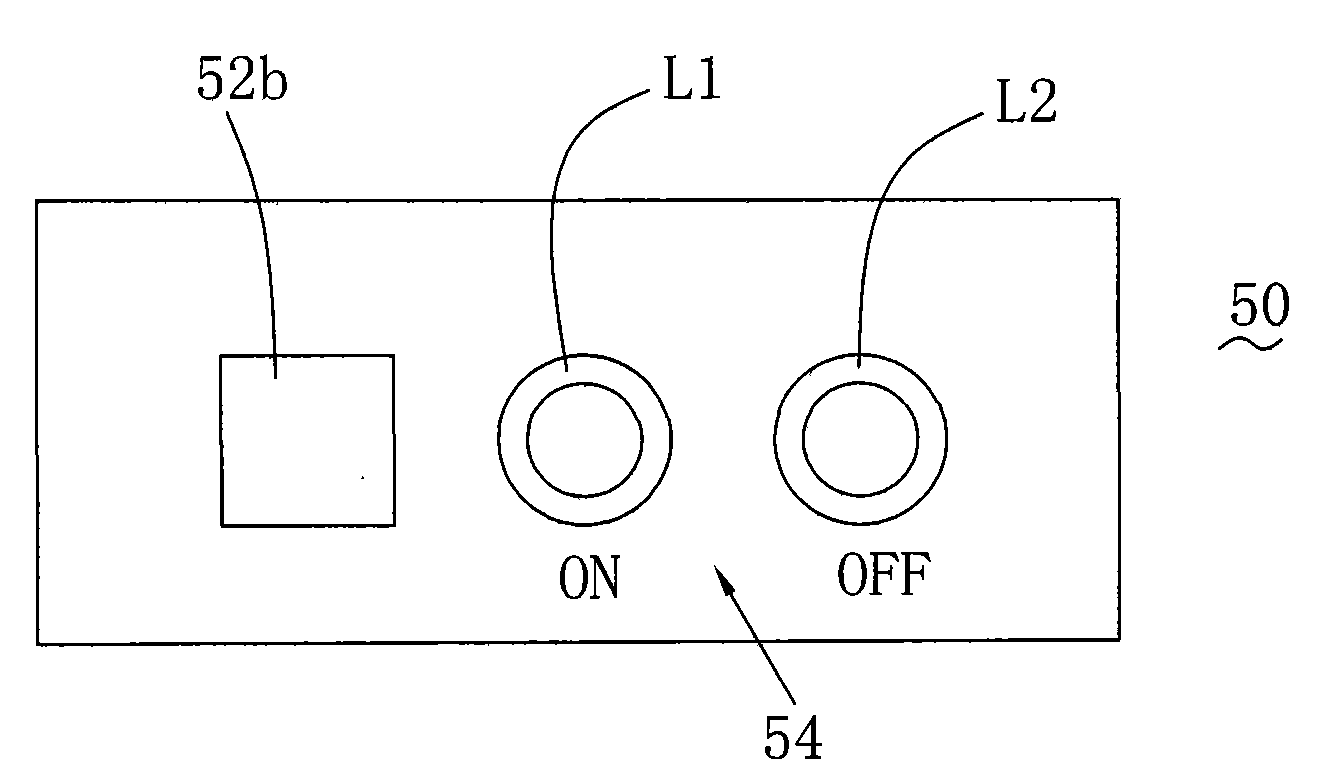

[0038] like figure 1 The electric screwdriver 2 shown includes: a casing 4, a motor 6 housed in the casing 4, a power supply 18 that provides current for the motor 6, and a working head 8 driven by the motor 6 to rotate, located in the casing 4 according to the working head The state change of 8 automatically reduces the control assembly 22 of the motor 6 speed and the control indicating device 50 which is arranged on the casing 4 and is electrically connected to the control assembly 22 . The electric screwdriver 2 also includes a switch 20 to control whether there is current passing through the motor 6 . The motor 6 drives the working head 8 to rotate to drill the screw 14 into the wooden board 16 . The motor 6 is connected with the clutch system 12 and the collet 10 through a mechanical spring to the working head 8 .

[0039] In this embodiment, the power source 18 is a DC power source, or a rechargeable battery, which can supply DC power to the motor 6 when the switch 20 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap