Controllable train tail system

A technology of row tail and row tail host, applied in the field of controllable row tail system, can solve the problem of uncontrollable control pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method of the present invention will be further described below through specific examples.

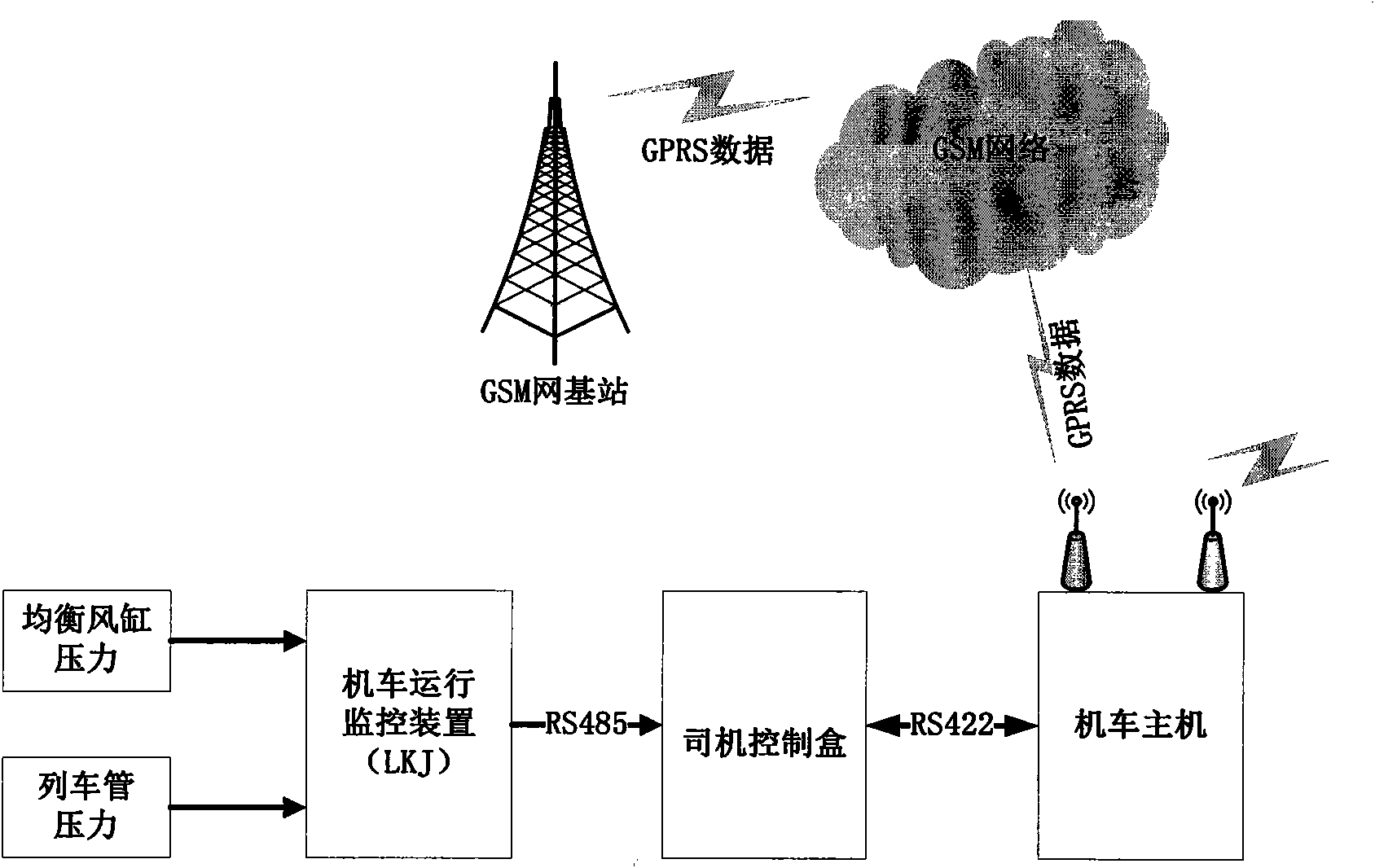

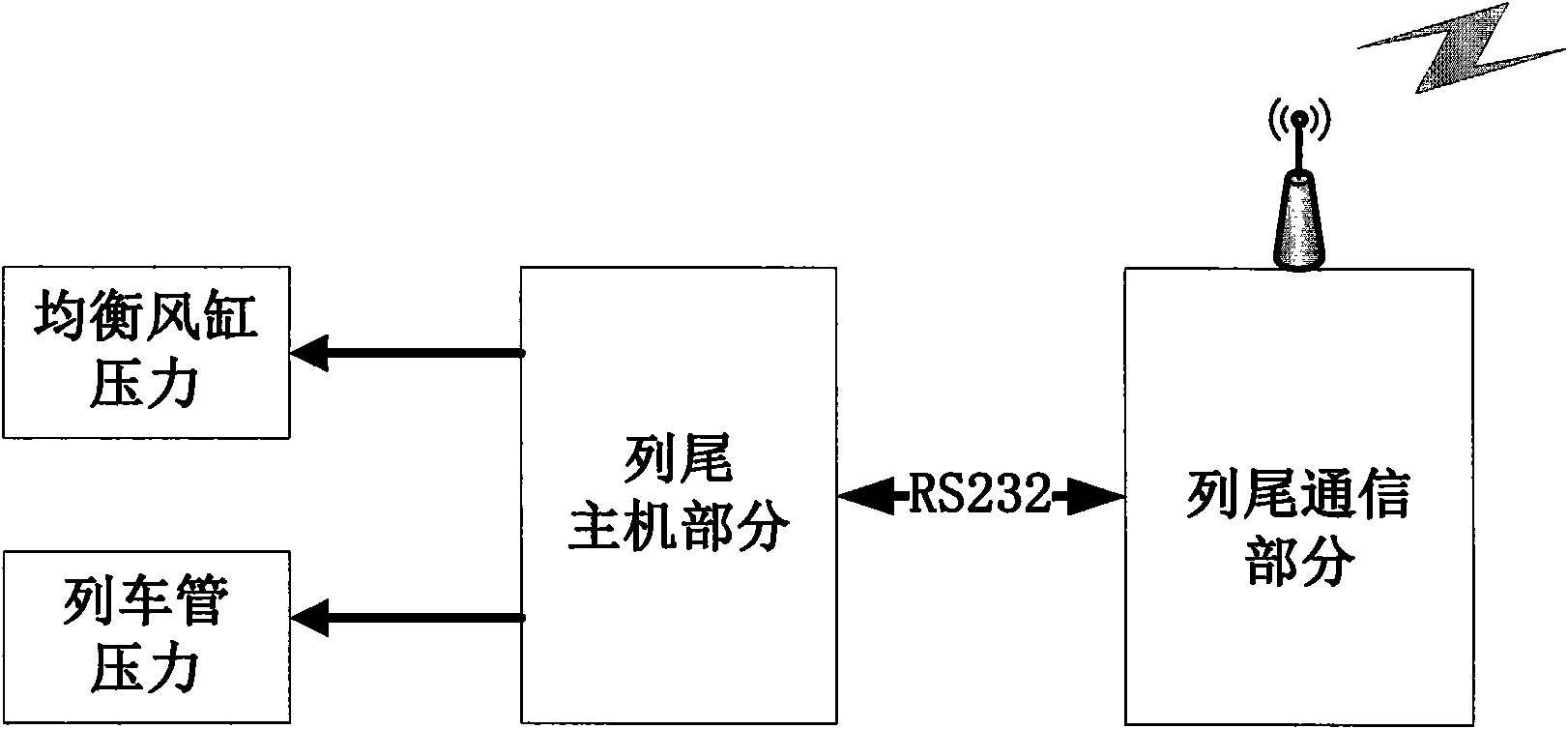

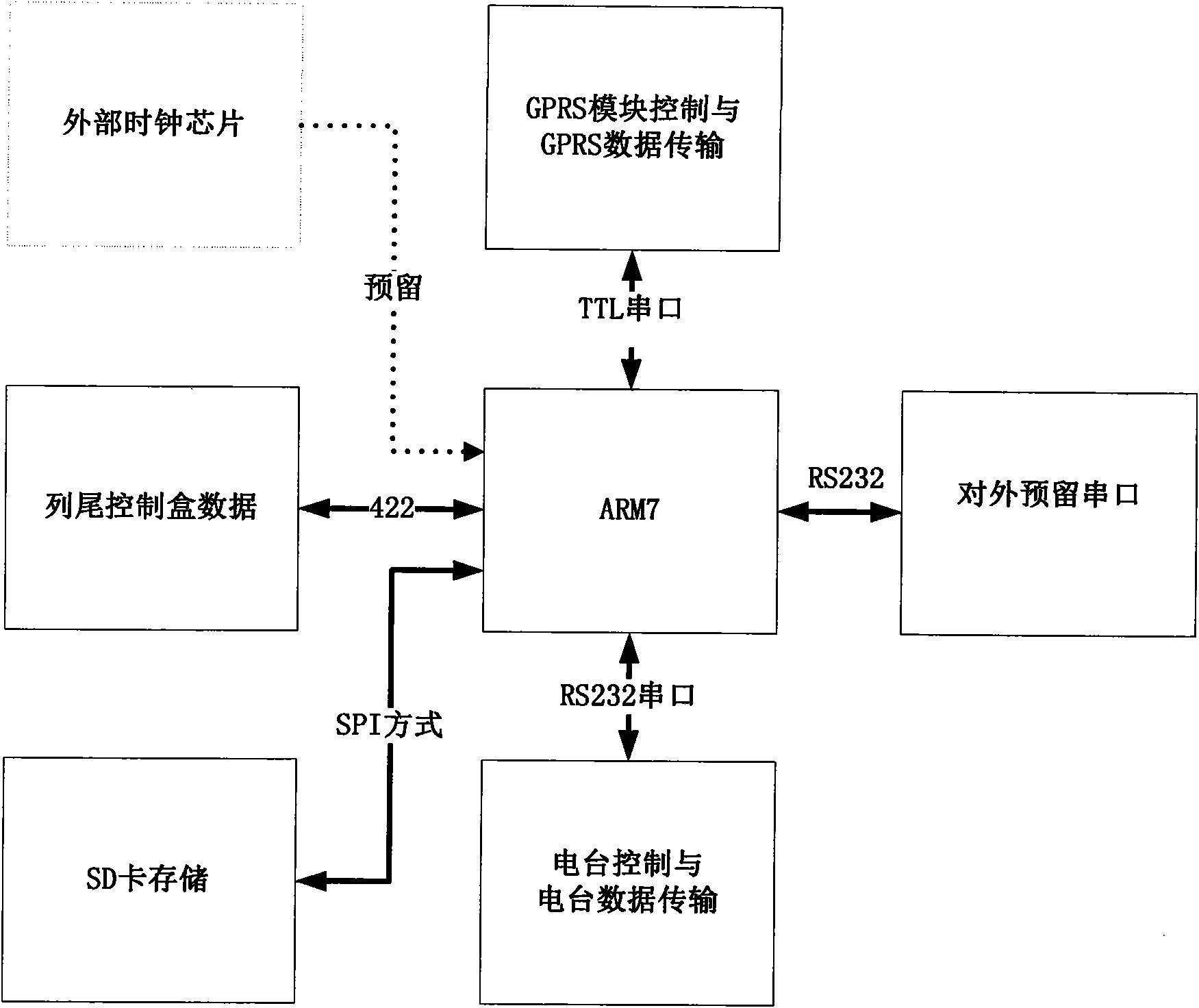

[0015] A controllable train tail system according to the present invention includes a locomotive part, a controllable train tail part, a monitoring and auxiliary maintenance system. The locomotive part includes a locomotive running monitoring device (LKJ), a train tail driver control box and a controllable train tail locomotive host; the controllable train tail part includes a controllable train tail host part and a controllable train tail train tail communication part, The control unit is included in the main unit. The locomotive host includes a GPRS communication module and a radio communication module; the tail end communication part adopts a 450MHz network radio communication mode.

[0016] When using the controllable train tail system of the present invention to perform train braking, the locomotive braking machine is operated to depressurize. At this time, the balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com