On-line detection method of blast furnace slag quantity

A detection method and technology of slag output, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unfavorable blast furnace refined production and standardized operation, inability to reflect blast furnace iron and slag discharge status in time, large random errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

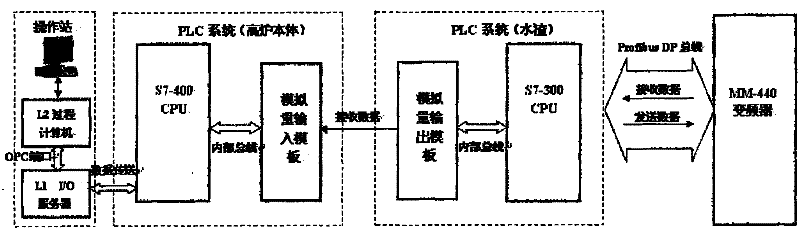

[0018] The method of the present invention has been used in Taiyuan Iron and Steel Group Co., Ltd. 1800m 3 Application on blast furnace. There are many blast furnace processes and equipment. The water slag system belongs to the peripheral auxiliary equipment of the blast furnace. The computer system of the blast furnace itself has no direct data collection and connection with the water slag dehydration drum inverter. Therefore, a multi-level data transmission method is adopted to transmit the current signal of the water slag dehydration drum frequency converter to the blast furnace process computer system for calculation and display.

[0019] The water slag drum frequency converter sends current and other data to the water slag PLC system through the network, and the water slag PLC system sends the data to the blast furnace body PLC system through a point-to-point (or network) form, and the blast furnace body PLC system sends the data to Blast furnace process computer system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com