Engine ignition coil and primary winding thereof

A technology for ignition coils and primary windings, applied in transformers, inductive energy storage devices, electrical components, etc., can solve problems such as inability to make better use of the internal structure of ignition coils, large potential differences, and coil failures, so as to improve stability and prolong The effect of service life and increased insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

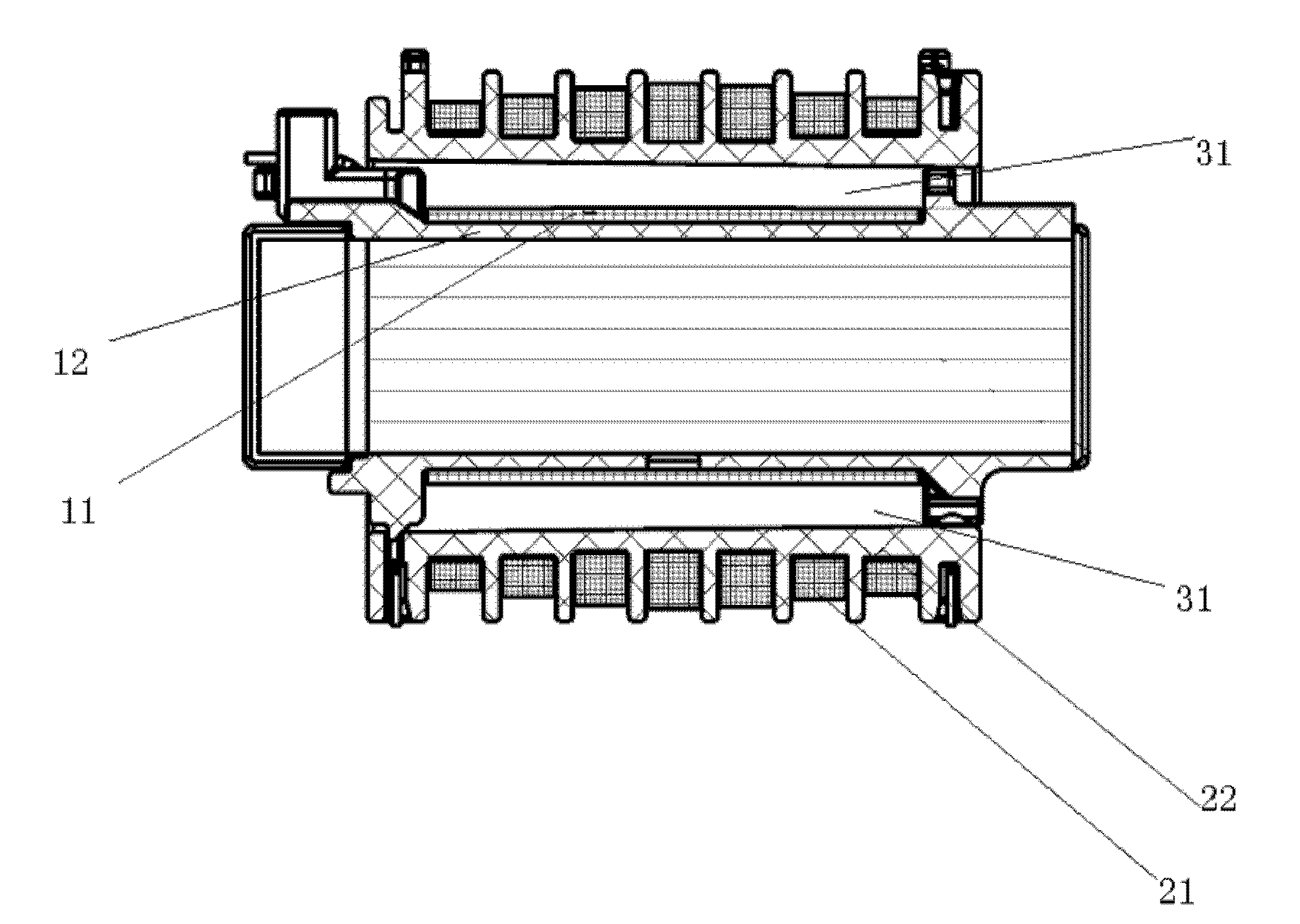

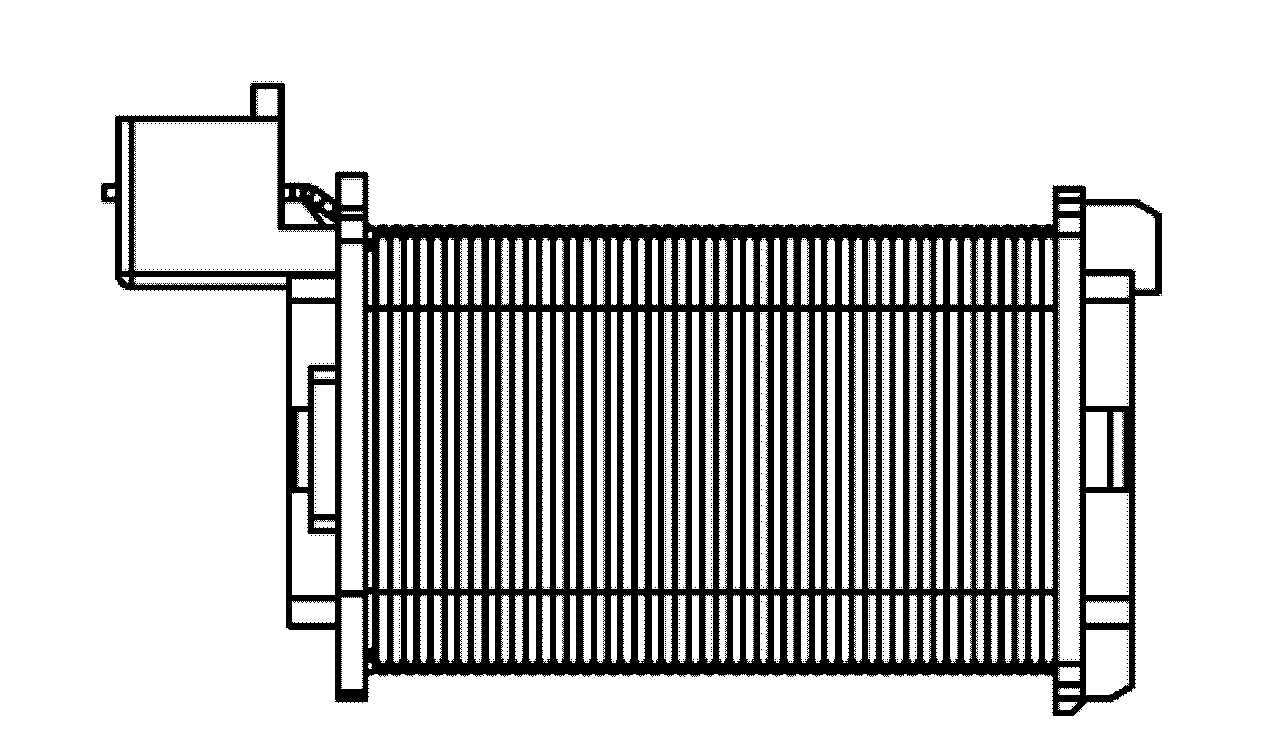

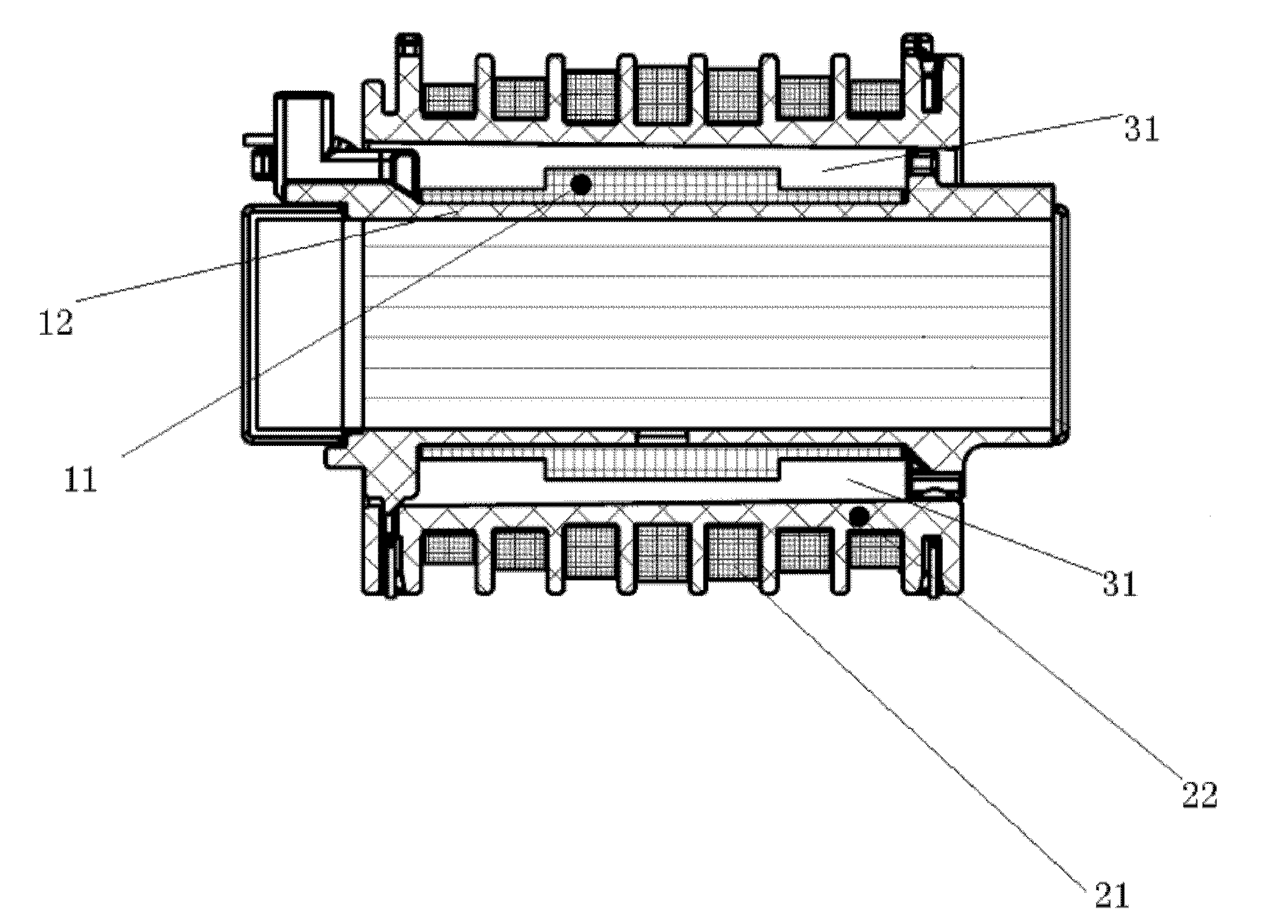

[0021] An embodiment of the engine ignition coil of the present invention is as image 3 As shown, including primary winding and secondary winding;

[0022] Secondary winding comprises secondary frame 22, secondary coil 21, and secondary winding is to wind enameled wire on secondary frame 22 as secondary coil 21, and the two ends of the enameled wire wound on secondary frame 22 are from secondary frame 22 Both ends lead out as the secondary coil ignition voltage output;

[0023] The primary winding includes a primary skeleton 12 and a primary coil 11. The primary winding is to wind an enameled wire on the primary skeleton 12 as the primary coil 11. The primary coil 11 is placed in the cavity formed by the inner wall of the secondary skeleton 22 of the secondary winding and the primary coil 11 is the same as There is an insulating distance between the inner walls of the secondary skeleton 22, and the insulating resin 31 is potted between the insulating distances;

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com