Liquid crystal display device and side-light backlight module thereof

A technology for a liquid crystal display device and a backlight module, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc. The effect of assembling the number of components, improving production efficiency, and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

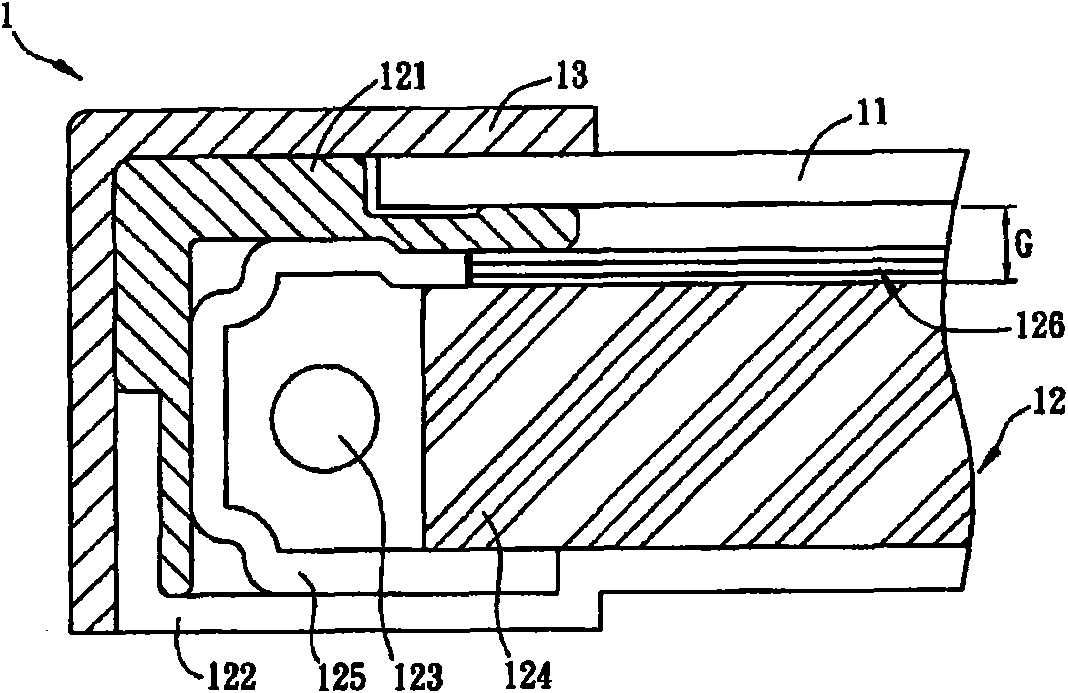

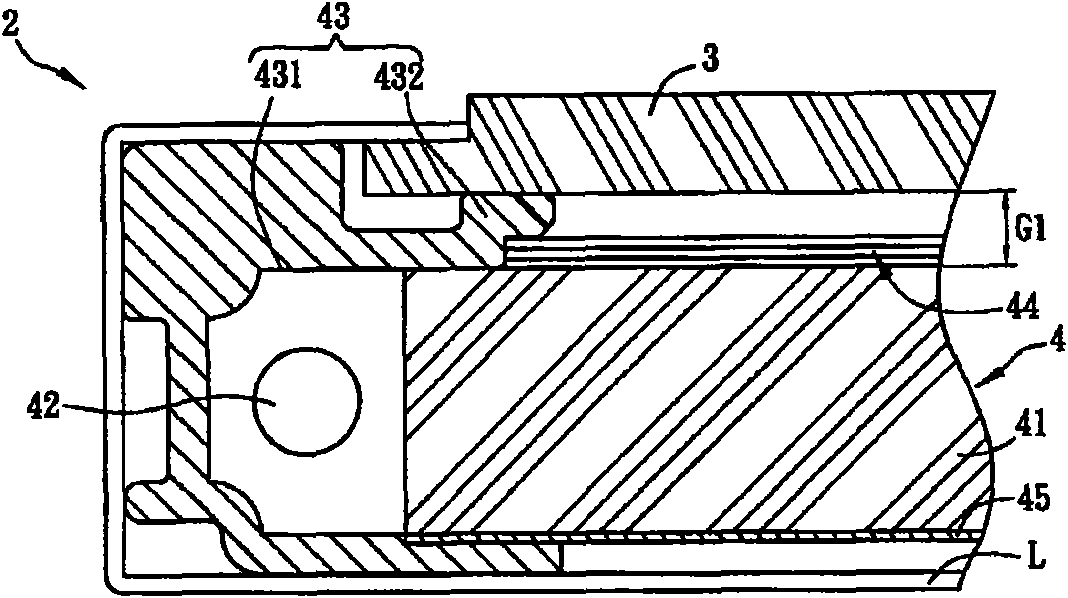

[0048] Please refer to figure 2 As shown, it is a partial cross-sectional view of the liquid crystal display device 2 according to the first embodiment of the present invention. The liquid crystal display device 2 can be applied to, for example, a liquid crystal display or a liquid crystal television, and the liquid crystal display device 2 includes a liquid crystal display panel 3 and an edge-lit backlight module 4 .

[0049] The liquid crystal display panel 3 includes structures such as a thin film transistor substrate, a color filter substrate, and a liquid crystal layer. exist figure 2 In order to clearly show the overall structure of the liquid crystal display device 2, the structure of the liquid crystal display panel 3 is omitted. However, in practical application, the liquid crystal display panel 3 should have these structures.

[0050] The edge-lit backlight module 4 is connected to the liquid crystal display panel 3 and has a light guide plate 41 , at least one l...

no. 2 example

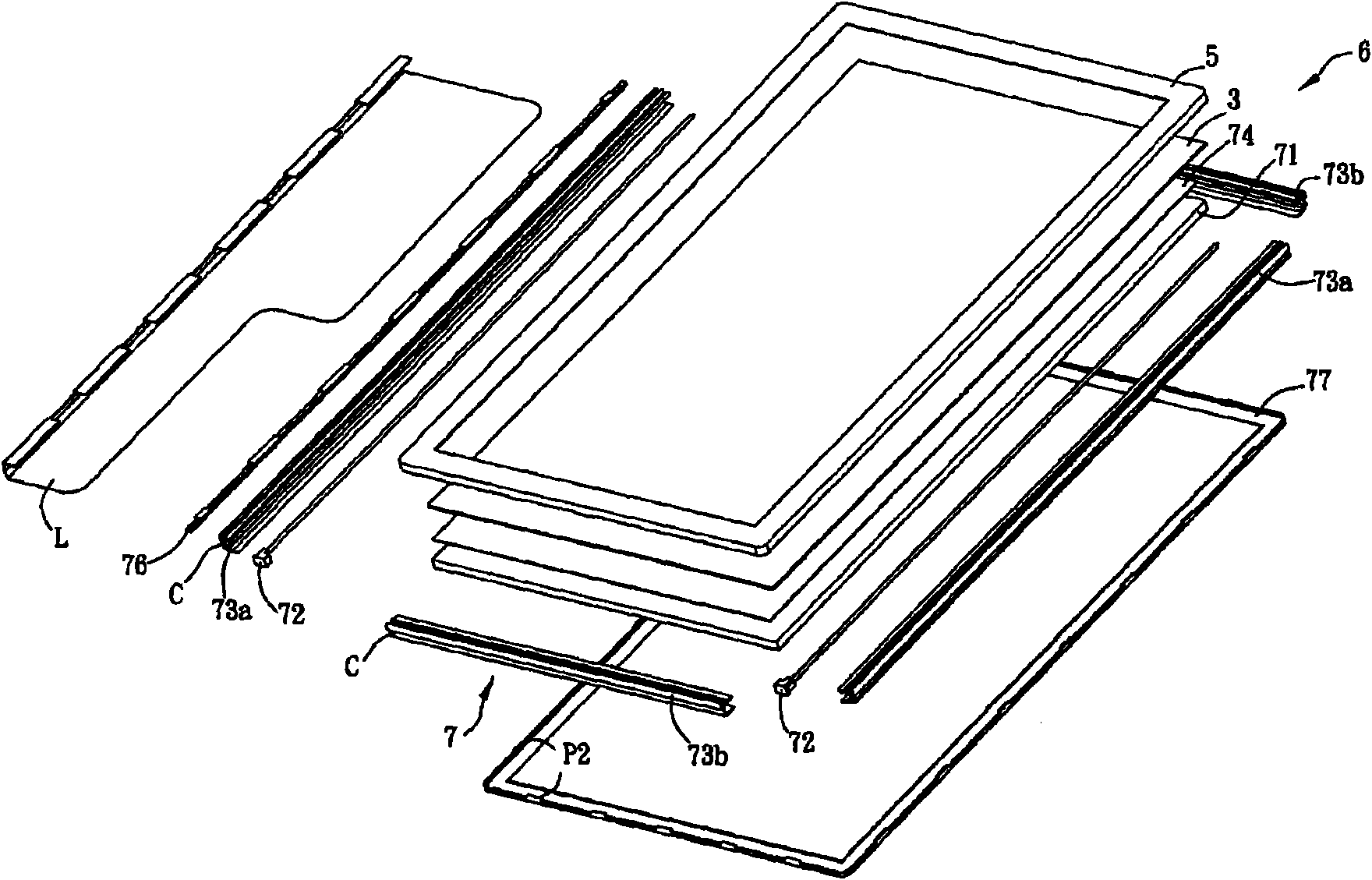

[0059] Please refer to Figure 3A , Figure 3B and Figure 3C shown, where Figure 3A It is an exploded view of the liquid crystal display device 6 according to the second embodiment of the present invention, Figure 3B It is a partial exploded view of the liquid crystal display device 6 according to the second embodiment of the present invention, Figure 3C It is a cross-sectional view of the assembled part of the liquid crystal display device 6 according to the second embodiment of the present invention. Note that, Figure 3B displayed as Figure 3A The part of the extruded component 73a and the alignment component 76 connected to the cable L on the middle left, in order to clearly show the detailed structure, Figure 3B Only part of the outer frame 5, the extruded component 73a, the alignment component 76 and the cable L are shown in the figure.

[0060] The difference between this embodiment and the first embodiment is that: the liquid crystal display device 6 can a...

no. 3 example

[0074] Please refer to Figure 7A to Figure 7C shown, where Figure 7A and Figure 7C are partial cross-sectional views of one side of the liquid crystal display device 8, 8a having the wiring L, respectively, according to the third embodiment of the present invention, Figure 7BIt is a partial cross-sectional view of one side of the liquid crystal display device 8 without the wiring L. In this embodiment, the liquid crystal display device 8, 8a may also include an outer frame 5 in addition to the liquid crystal display panel 3 and the side-light backlight module 9, 9a. The edge-lit backlight modules 9, 9a are connected to the liquid crystal display panel 3, and in addition to having a light guide plate 91, at least one light-emitting component 92, 92a and an extruded component 93, it may also have an optical film set 94, a reflective film 95 and a back plate 97. The outer frame 5 , the back plate 97 and the extruded component 93 are fastened to the extruded component 93 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com