LED (Light Emitting Diode) optical lens

An optical lens and body technology, applied in the field of LED optical lenses, can solve the problems of high cost, difficult to manufacture, and complex structure, and achieve the effects of low cost, reduced discomfort, and controlled glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

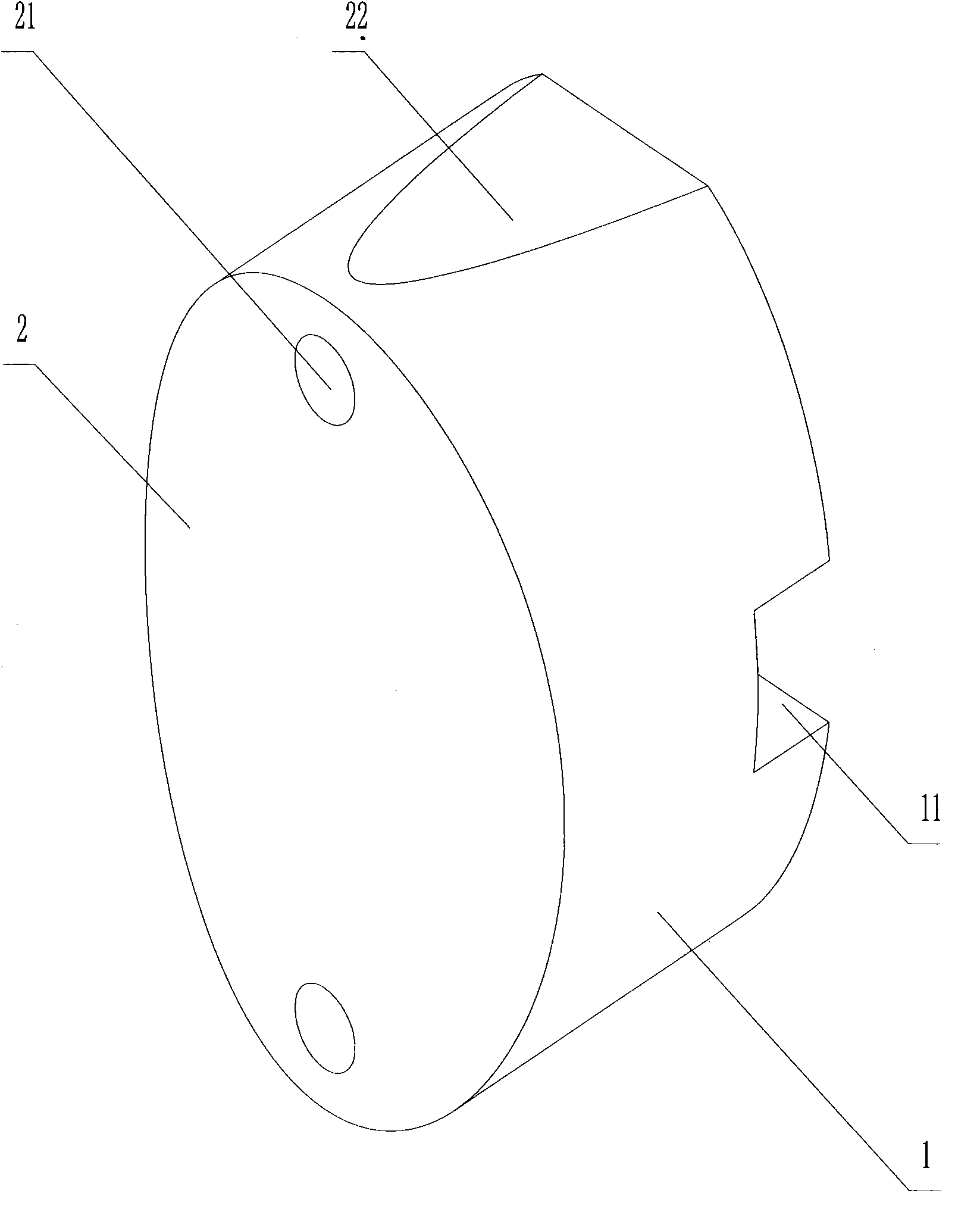

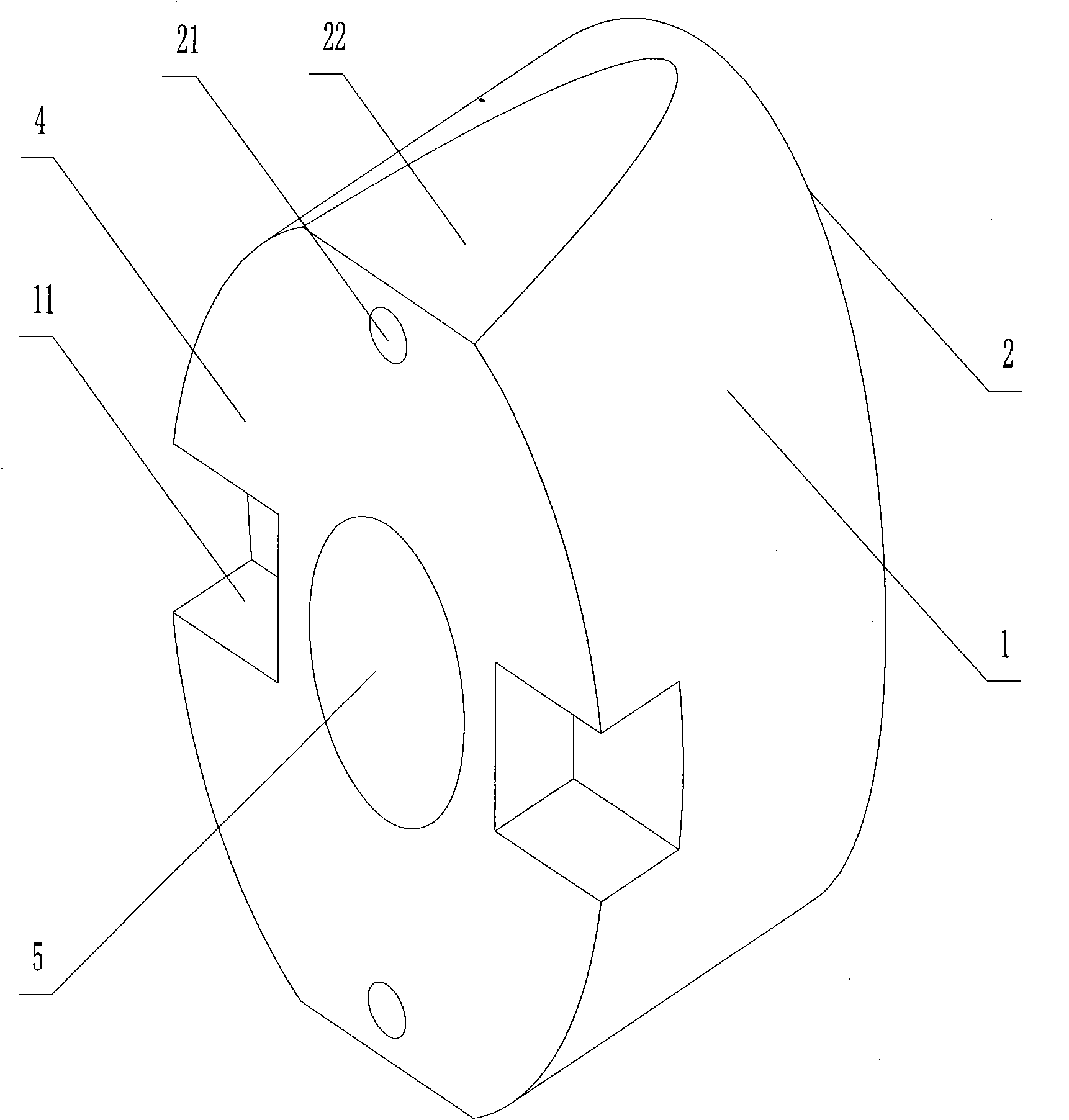

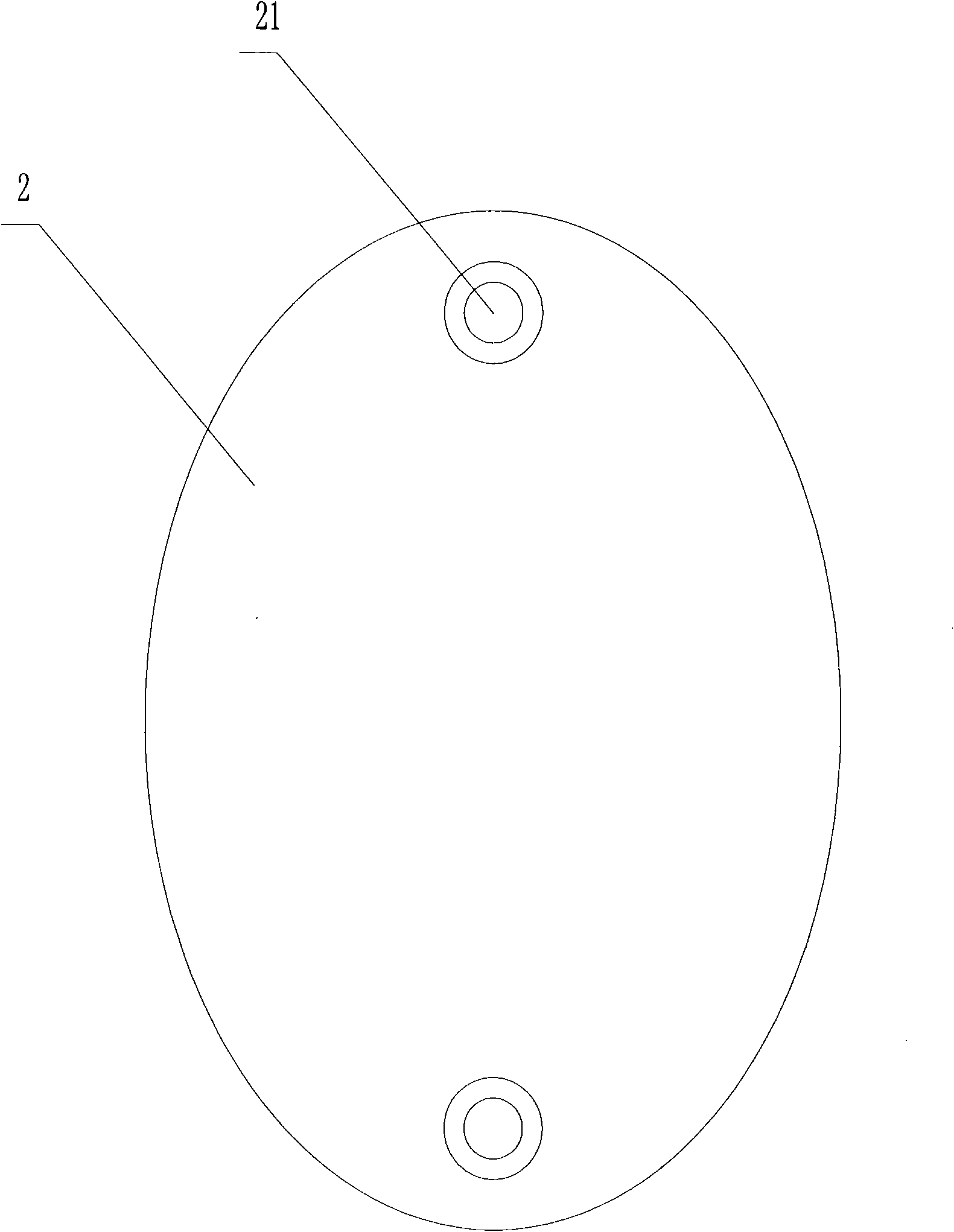

[0019] Such as Figure 1 to Figure 6 As shown, the LED optical lens, the entire light-transmitting body 1 is embedded in the lamp hole of the LED lighting handrail. The light-transmitting body 1 is generally a cylinder with an elliptical cross-section. The exit surface 2 is consistent with the surface arc surface of the lighting handrail. The exit surface 2 is an elliptical surface with a protruding middle and a smooth transition to the edge, and the surface has been frosted. The internal structure and structure cannot be seen from the exit surface 2. part. The bottom 4 of the light-transmitting body 1 is a plane, and the middle part of the bottom 4 has a groove 5 for accommodating LED lamp beads. The inner surface of the groove 5 is a hemispherical total incidence surface. Two rectangular notches 11 are formed at both ends of the ellipse's short axis direction on the bottom 4, and the rectangular notches 11 are used to accommodate the solder joints on the substrate to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com