Pressing device of integral shunt reactor body

A press-fitting device and reactor technology, which is applied in the manufacture of inductors/transformers/magnets, transformers/inductor coils/windings/connections, circuits, etc., can solve the problems of difficulty in securing the tightening force at the tie rod and complicated operation, etc. Achieve the effect of improving work efficiency and product quality, easy operation and accurate pressure adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

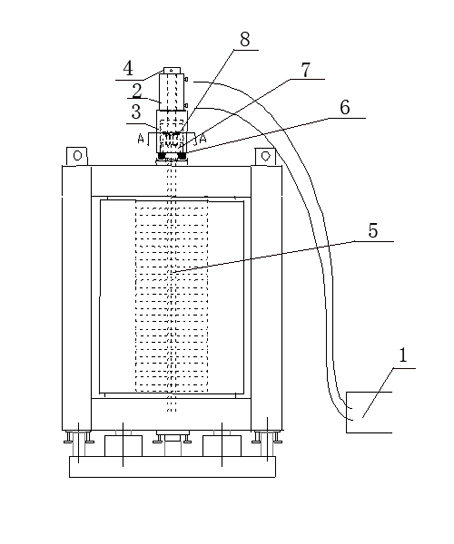

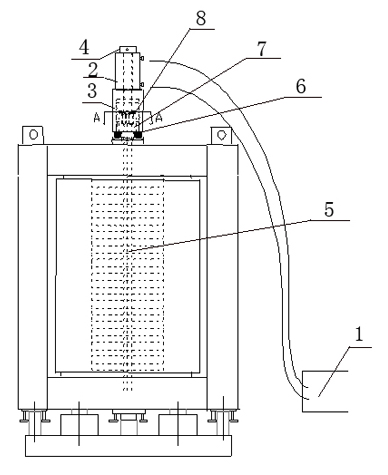

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0012] In the embodiment, the overall press-fit device of the shunt reactor body includes a hydraulic pump 1, a hollow hydraulic cylinder 2, a press-fit sleeve 3, a tightening screw 4, a reactor core rod 5, and a butterfly spring 6. The hydraulic pump is connected to the hollow hydraulic Oil cylinder, the hollow hydraulic cylinder is set above the press-fitting sleeve, the tension screw passes through the hollow hydraulic cylinder and the press-fit sleeve, one end of the tension screw is connected to the iron tie rod of the reactor, and the iron core tie rod of the reactor passes through the butterfly Spring, the press-fitting sleeve is pressed on the butterfly spring; since the tightening screw has been connected with the iron core rod, in this way, when the hydraulic pump is pressurized to make the hollow cylinder lift up, the press-fitting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com