Heat abstractor

A heat dissipation device and heat dissipation fin technology, which is applied in the direction of heat dissipation fins, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as easy overlapping, increased gaps, and reduced overall length of heat dissipation fin groups. The effect of reducing, not easily deformed, and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

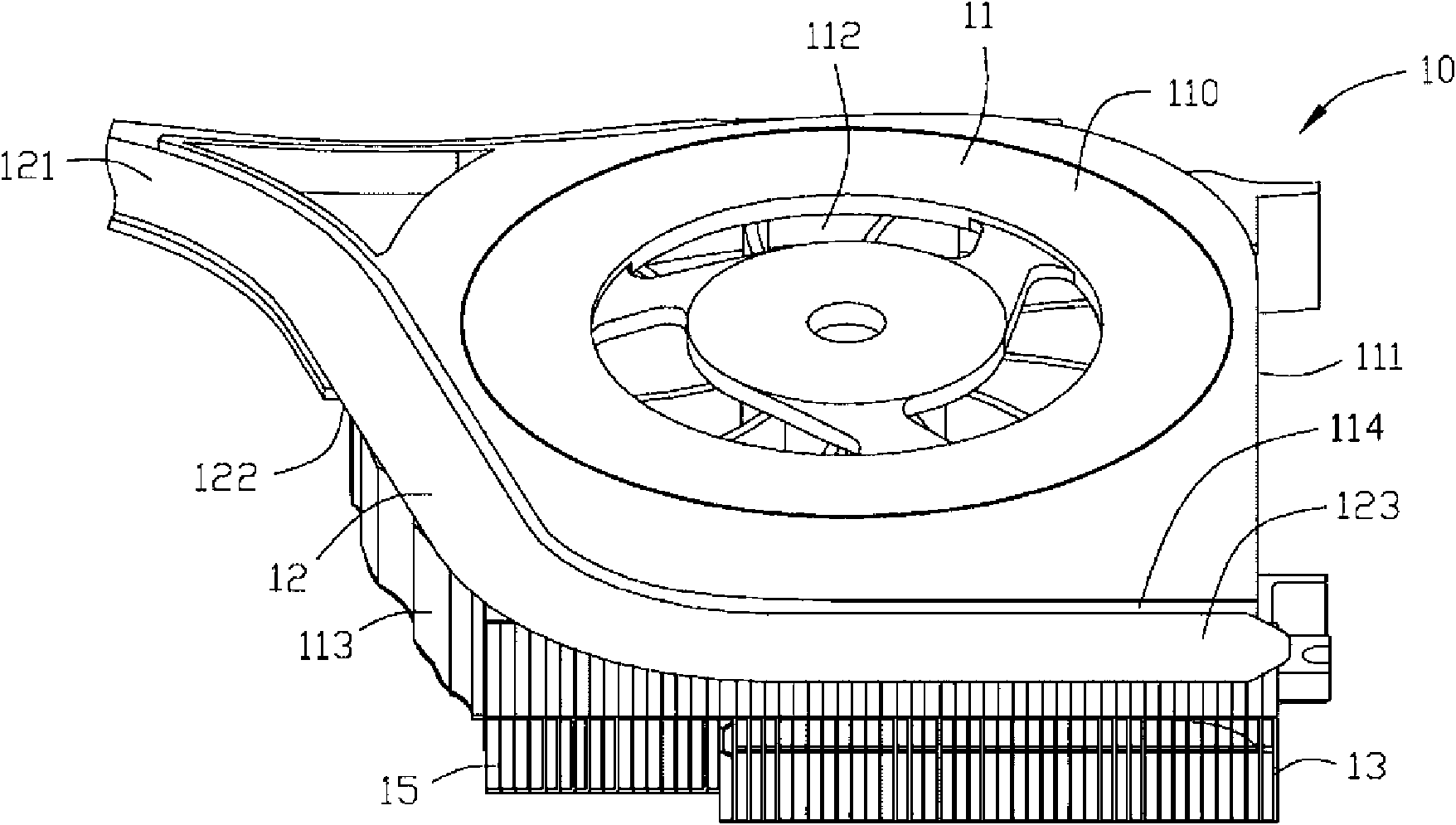

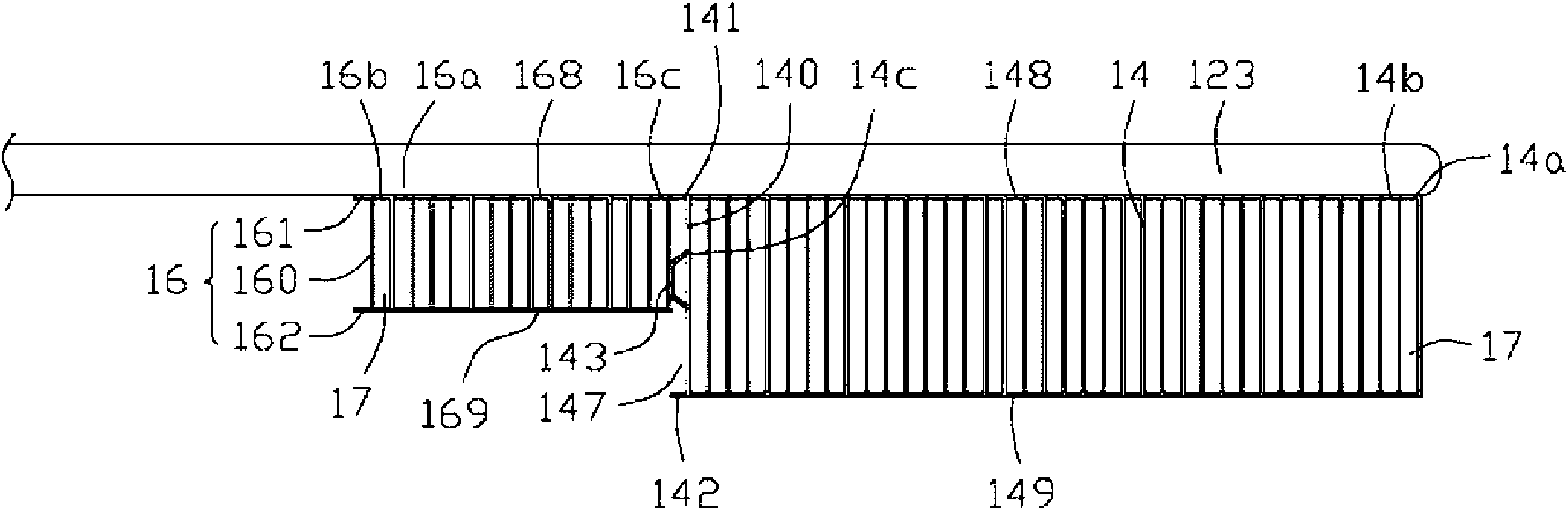

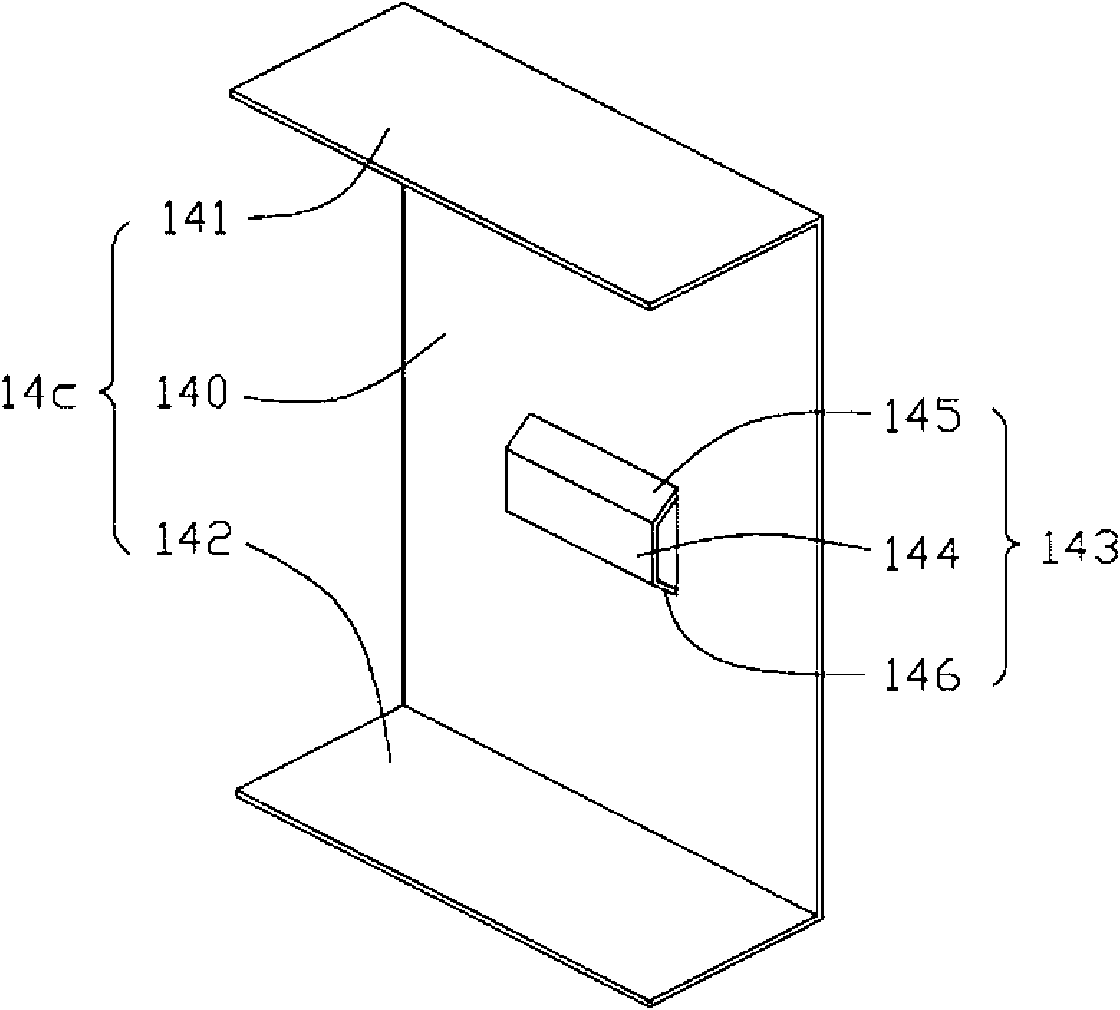

[0012] Such as figure 1 and figure 2 As shown, the heat dissipation device 10 includes a heat dissipation fan 11 , a heat pipe 12 , a first heat dissipation fin set 13 and a second heat dissipation fin set 15 . The top 110 and the bottom 111 of the cooling fan 11 are provided with an air inlet 112 , and the sidewall 113 of the cooling fan 11 is provided with an air outlet 114 . The heat pipe 12 is a flat heat pipe. The top surface 121 and the bottom surface 122 of the heat pipe 12 are flat. The first heat dissipation fin group 13 and the second heat dissipation fin group 15 are located at the air outlet 114 of the heat dissipation fan 11 and are arranged in a row and attached to the bottom of the condensation section 123 of the heat pipe 12. The second heat dissipation fin group 15 is located at the first heat dissipation On the left side of the fin set 13 , the height of the second heat dissipation fin set 15 is smaller than the height of the first heat dissipation fin set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com