Steel tube UV-curing color-painting mechanism

A coloring and ultraviolet technology, applied in coatings, devices for coating liquids on surfaces, surface pretreatment, etc., can solve problems such as affecting production efficiency, affecting anti-corrosion effect, and easy peeling and falling of paint, and achieves improved work efficiency. Efficiency, the effect of improving the color circle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

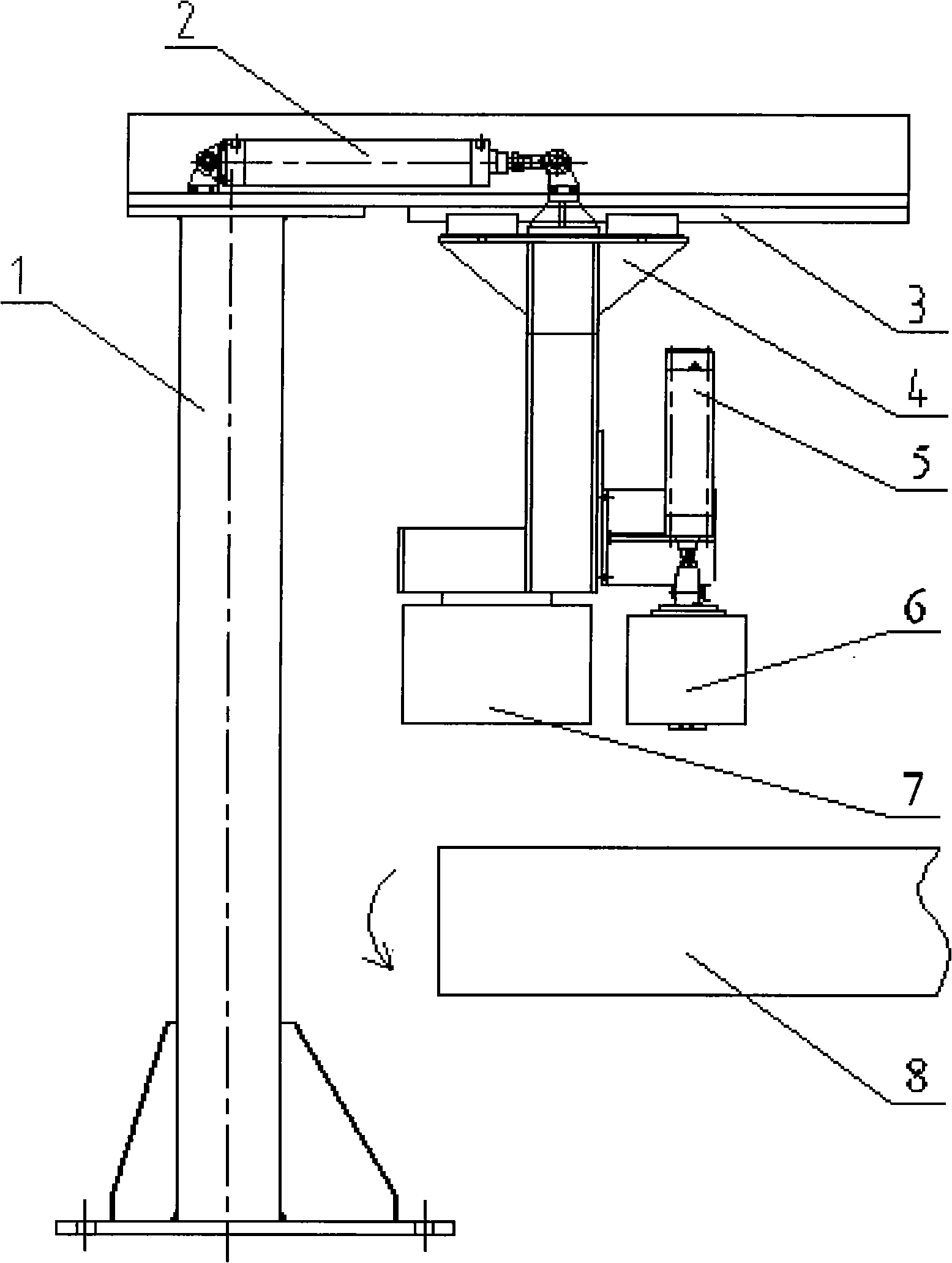

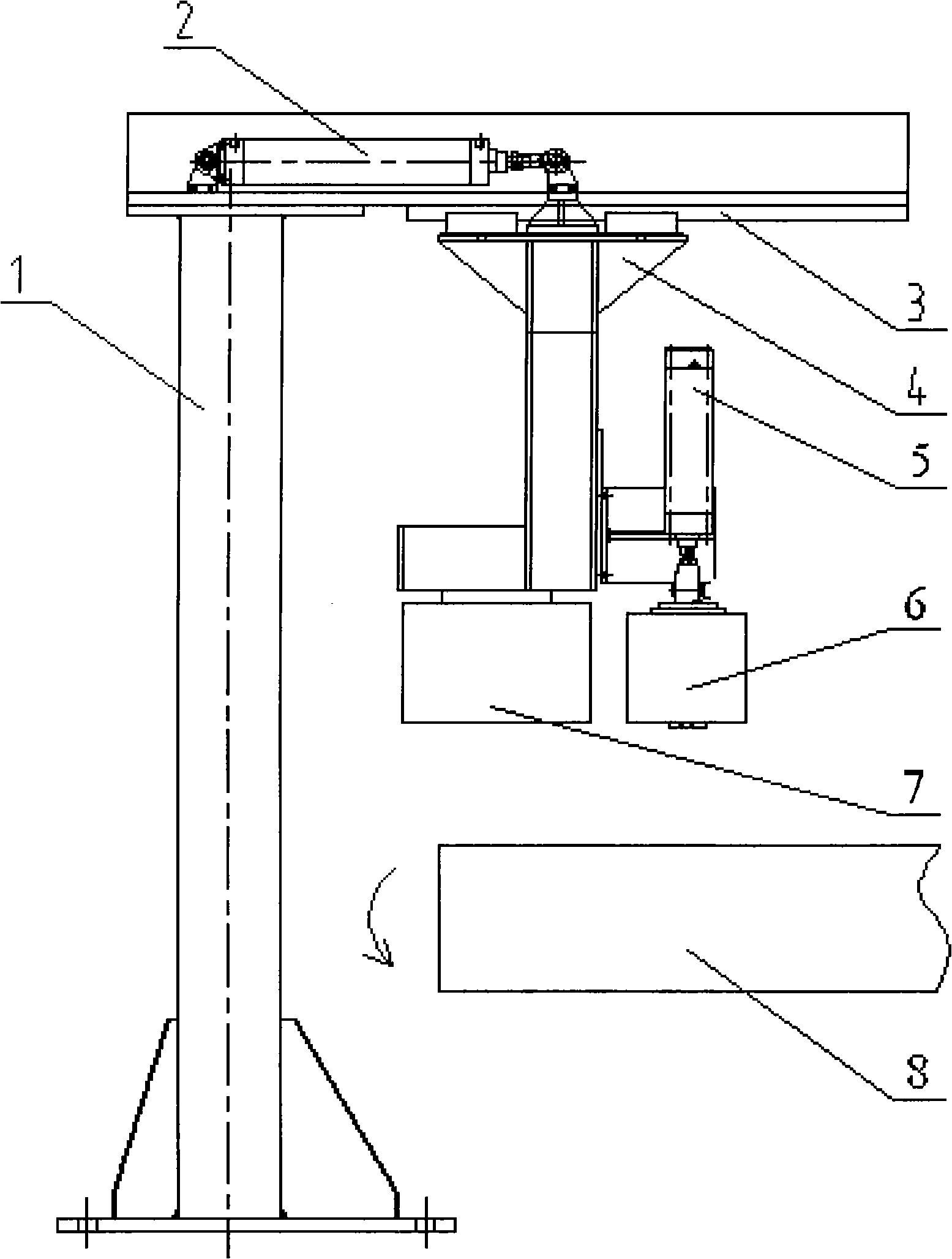

[0015] Such as figure 1 As shown, the present invention is horizontally installed with the guide rails of cylinder 2 and two linear guide rail pairs 3 on the cantilever beam support 1, the cylinder 2 is located in the middle of the two guide rails, the piston rod end of the cylinder 2 and the sliders of the two linear guide rail pairs 3 They are fixedly connected with the support 4 of the lifting cylinder respectively, and the piston rod of the cylinder 2 is stretched to drive the support 4 to move horizontally along the linear guide pair 3; It is fixedly connected with the rubber roller coloring device 6 below, and the rubber roller coloring device 6 is driven to move vertically by the expansion and contraction of the piston rod of the lifting cylinder 5, and the ultraviolet lampshade 7 is installed on the other side of the lower end of the support 4.

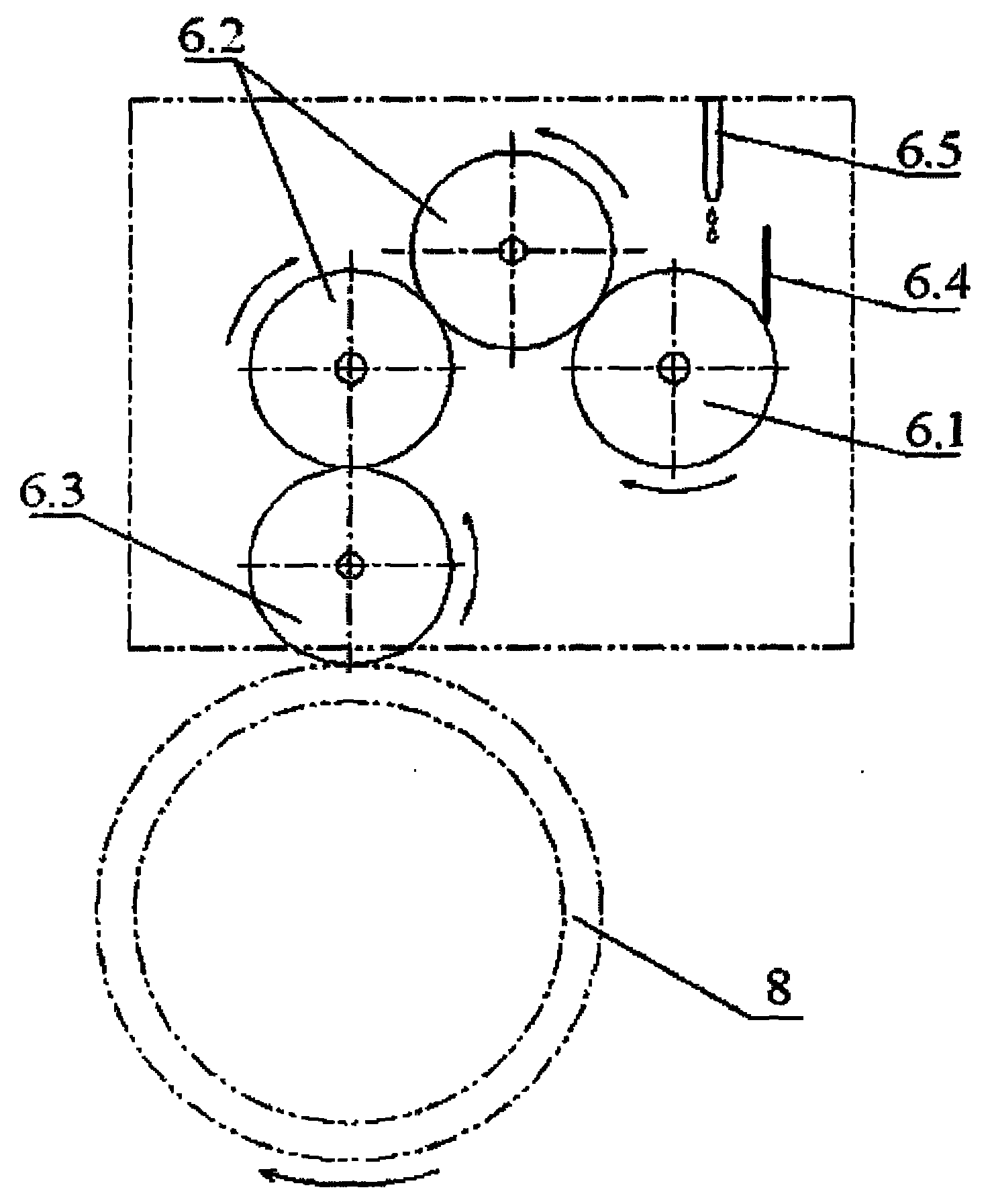

[0016] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com