Coarse fraction powder concentrator

A powder classifier and coarse-grained technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of complex classification system, difficult lifting and sorting, grading, etc. Achieve the effect of high efficiency, long service life and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

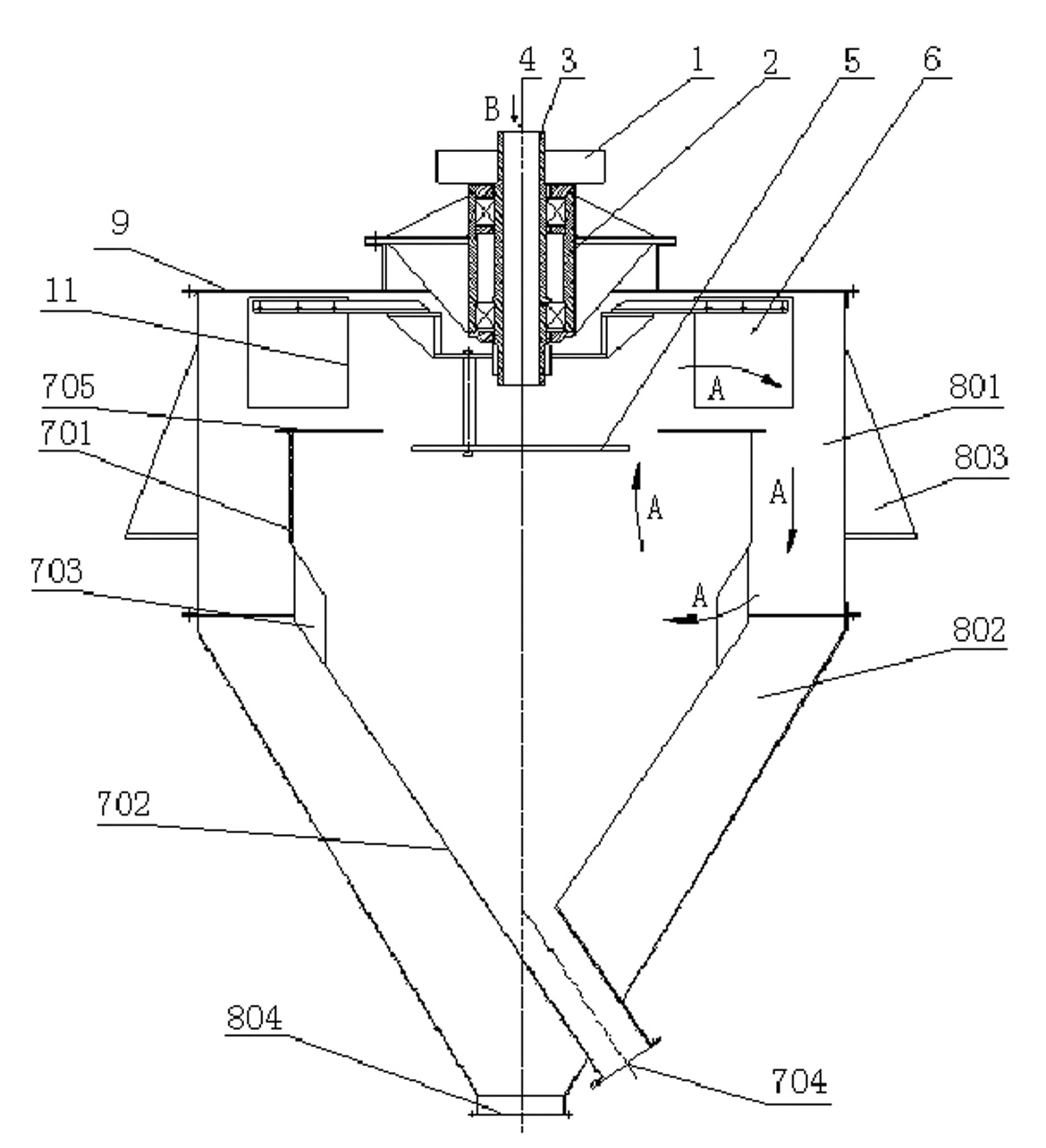

[0019] refer to figure 1 , this embodiment includes a machine base 803, a bearing seat 2, a transmission wheel 1, a hollow main shaft 3, a spreading disc 5, a large fan blade 6, an inner casing, and an outer casing, and the bearing seat 2 is installed on the machine cover 9; The hollow main shaft 3 is installed on the bearing seat 2 through a bearing, and the feeding port is arranged above the hollow main shaft; the transmission wheel 1, the spreading disc 5, and the large fan blade 6 are assembled on the hollow main shaft 3 to form a rotatable rotor part ,; the outer casing is composed of two parts: the upper outer casing 801 and the lower outer casing 802. The machine base 803 is arranged outside the outer casing for the installation of the machine, and the lower part of the lower outer casing 802 is provided with a fine powder outlet 804; the inner The casing is placed in the inner cavity formed by the outer casing. The inner casing is composed of an upper inner casing 701 ...

Embodiment 2

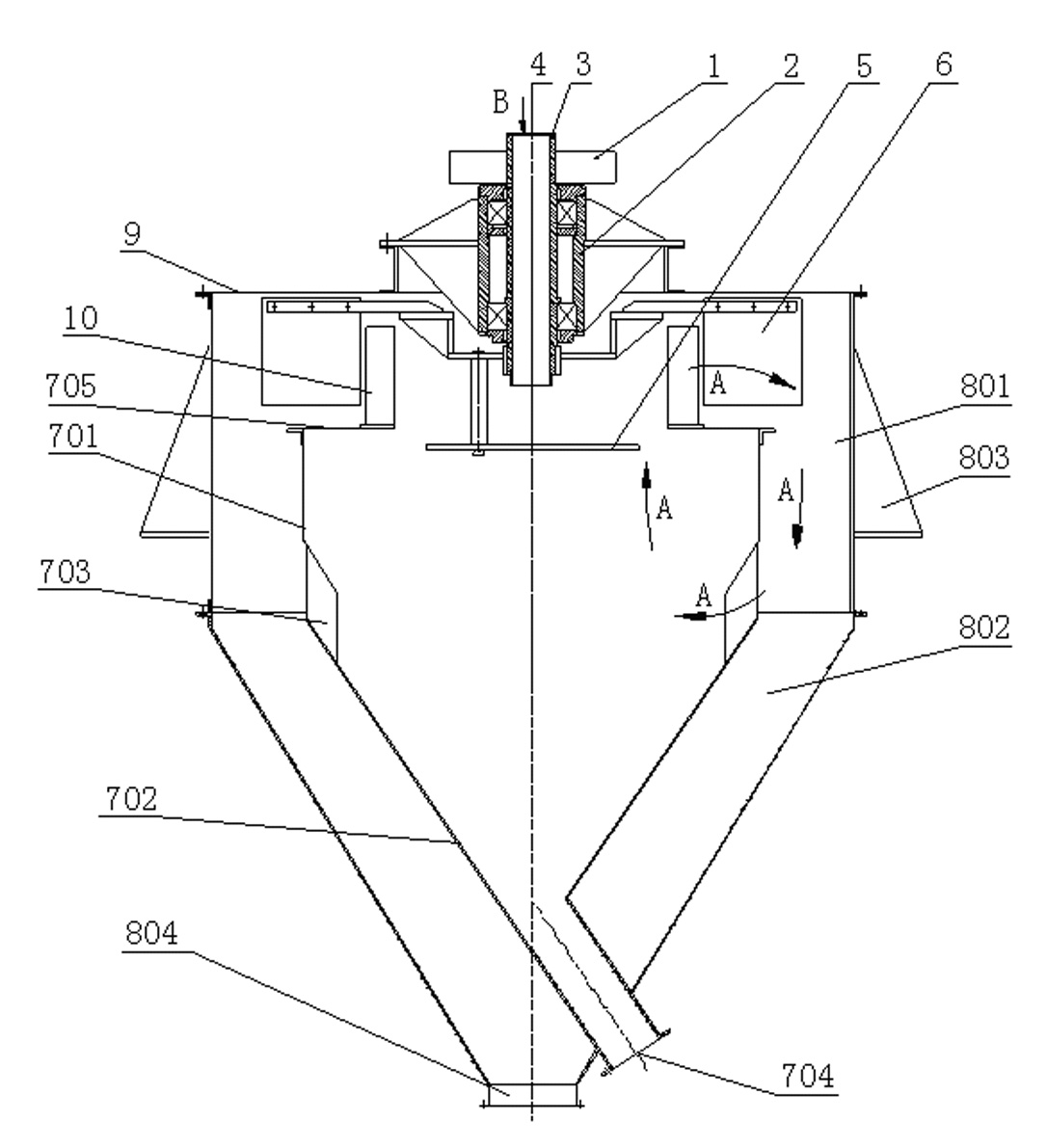

[0022] refer to figure 2 The difference between this embodiment and Embodiment 1 is only that a through-type annular powder separating blade 10 is added between the opening above the upper inner casing 701 and the cover 9 . The rest are the same as in Example 1. Only the fine materials that meet the particle size requirements can enter the fine powder area through the through-type annular powder separation blade 10 to realize the second classification, which is conducive to the realization of strict control of the particle size of the fine powder. The structure is simple and the classification efficiency is high.

Embodiment 3

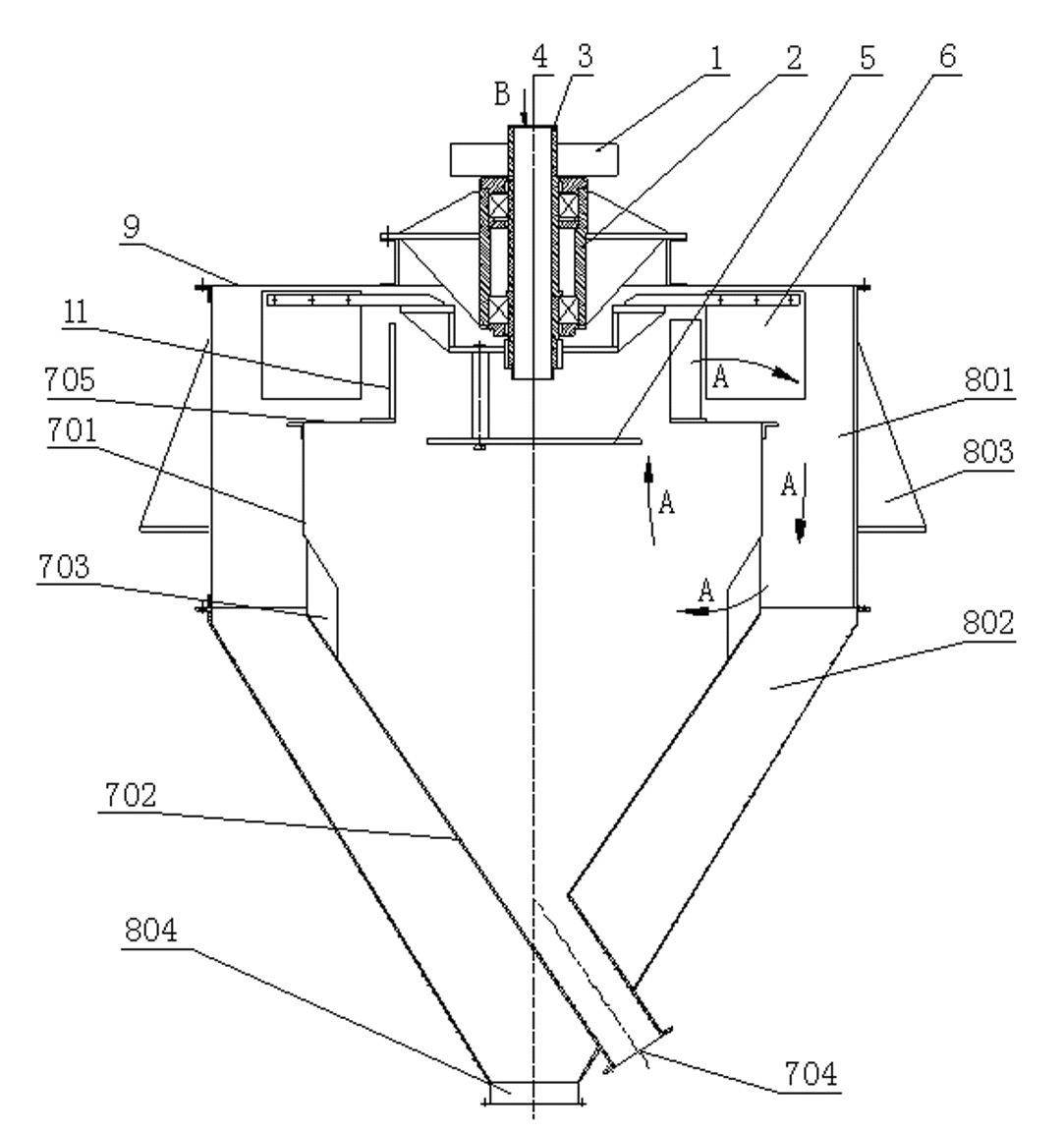

[0024] refer to image 3 , the difference between this embodiment and the first embodiment is only that a screen 11 is added between the upper inner casing 701 and the cover 9 . The rest are the same as in Example 1. Only the fine powder materials that pass through the sieve holes of the screen mesh 11 can enter the fine powder area, and the second classification is realized, which is conducive to the strict control of the particle size of the fine powder.

[0025] The sieve 11 is different from ordinary sieves for screening materials in two points: First, the materials entering the sieve have been classified by air flow, and the sieve only needs to block a small amount of coarser grades from entering the fine powder area, and does not need to be processed like ordinary sieves. All materials; Second, the materials entering the screen are suspended in the gas, the screening efficiency is high and the screen holes are not easily blocked, unlike ordinary screens that rely on gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com