Hot-extrusion die for molding multi-core cavity aluminum alloy profile and flow supply method

A technology of aluminum alloy profiles and hot extrusion dies, which is applied in the field of metal supply and hot extrusion dies for multi-core cavity aluminum alloy profiles. Strength, machining accuracy can not be guaranteed, etc., to achieve the effect of convenient metal flow supply and metal flow direction, stable forming, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

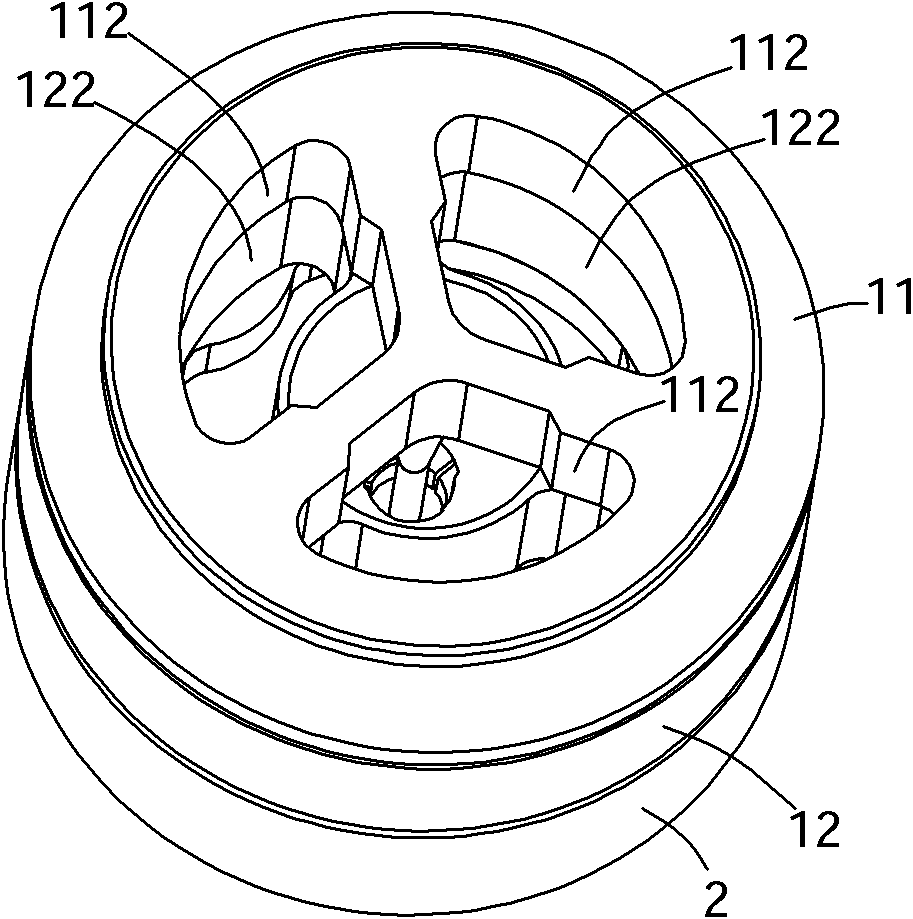

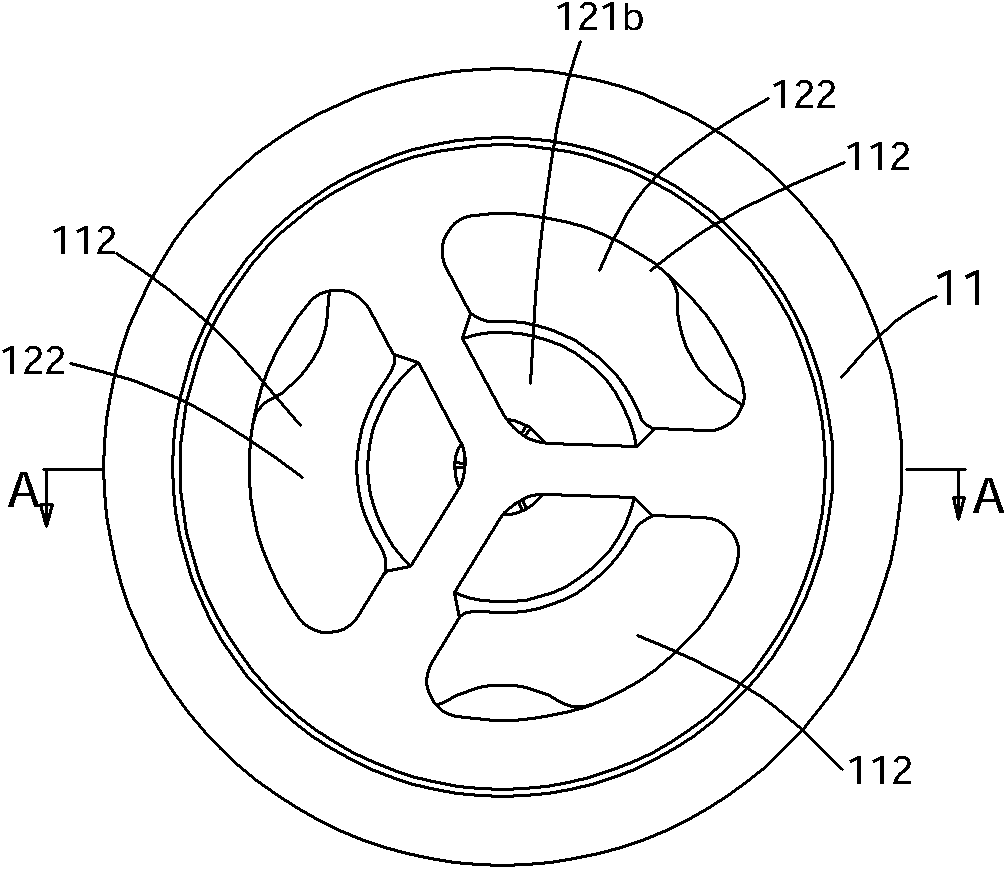

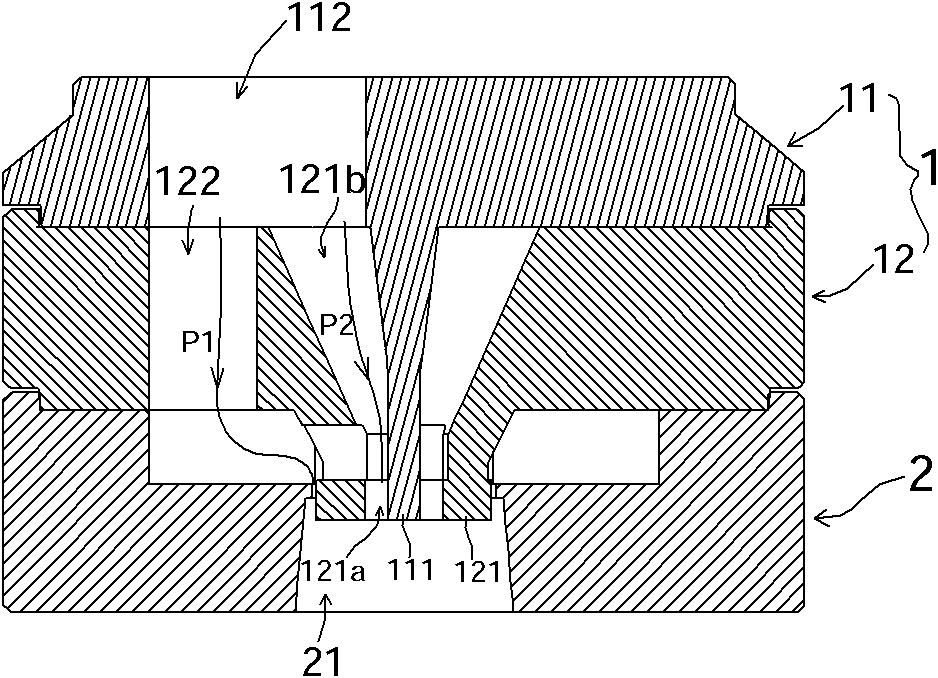

[0018] The inventor of the present invention utilizes long-term accumulated practical experience and mold design expertise, and aims at the defects existing in the existing multi-core cavity aluminum alloy profile extrusion die, and invents a metal flow method with independent internal and external flow, and on this basis A hot extrusion die for forming multi-core cavity aluminum alloy profiles is proposed. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The method of the present invention for hot-extruding aluminum alloy profiles with multi-core cavities is as follows: adopt a combined upper mold consisting of an upper mold and a lower mold, set a number of first flow holes in the upper mold layer, and set a number of first flow holes in the lower mold The top is provided with a third split hole coaxial with the inner mold hole, and a number of second split holes running through the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com