Method for producing side plate of dump truck bed

A production method and dump truck technology, applied in the field of truck boxes, can solve the problems of high production efficiency, high manual labor intensity, and more electric energy, and achieve the effects of reducing electric energy consumption, stabilizing product quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

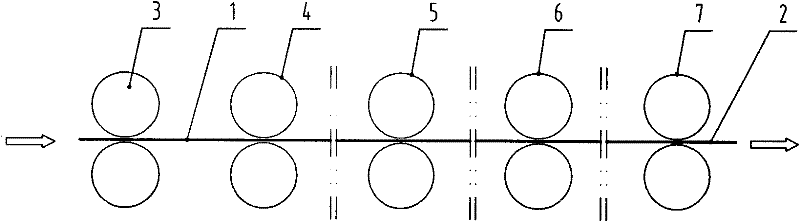

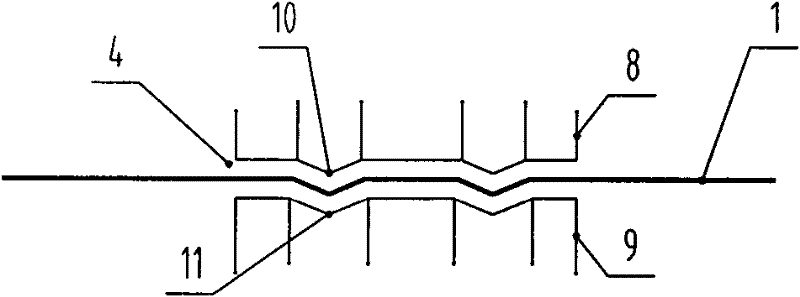

[0014] Such as Figure 1~6 As shown, in the production method of the dump truck box side plate of the present invention, the coiled plate is first processed into a flat plate 1 of required length and width. A box body side panel 2 with a reinforcing rib. Rolling and cold bending forming production line includes feeding roller group 3, forming roller group 4 (the last one of the first stage forming roller group), forming roller group 5 (the last forming roller group of the second stage) arranged side by side ), forming pressure roller group 6 (the last one of the third stage forming pressure roller group) and the last forming pressure roller group 7 (the last one of the fourth stage forming pressure roller group), wherein each section forming pressure roller group consists of 2~ Consists of 5 forming pressure roller groups. The number of forming pressure roller groups generally requires more than ten. The plate 1 first passes through the feeding roller group 3 for rolling, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com