Molding device of corrugated plate

A forming equipment and corrugated board technology, which is applied in the field of corrugated board forming equipment, can solve the problems of high cost, hindering the application of board type, inconvenient adjustment of wave peak, wave height and wave distance, etc., and achieve low rigidity, simple and beautiful appearance, and board The effect of uniform head waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

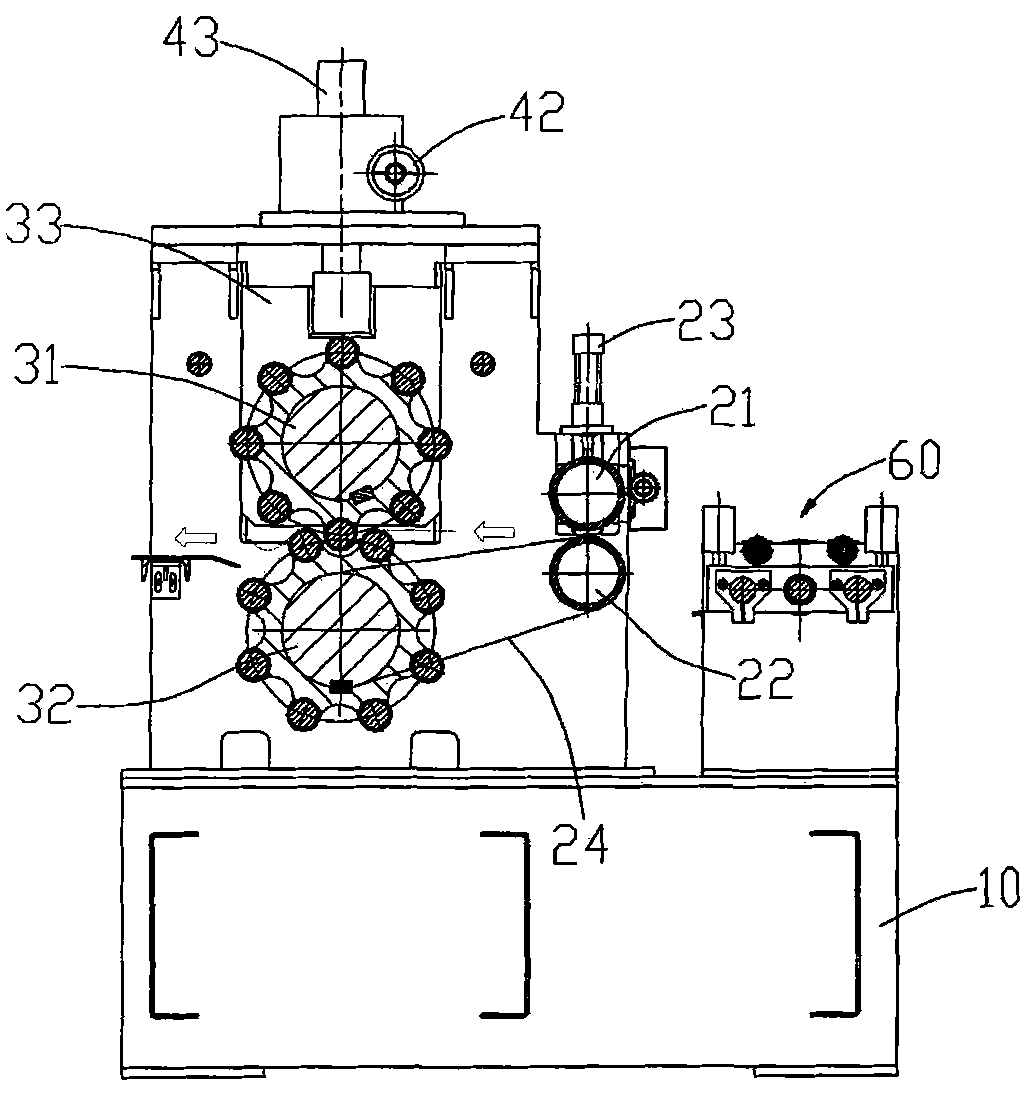

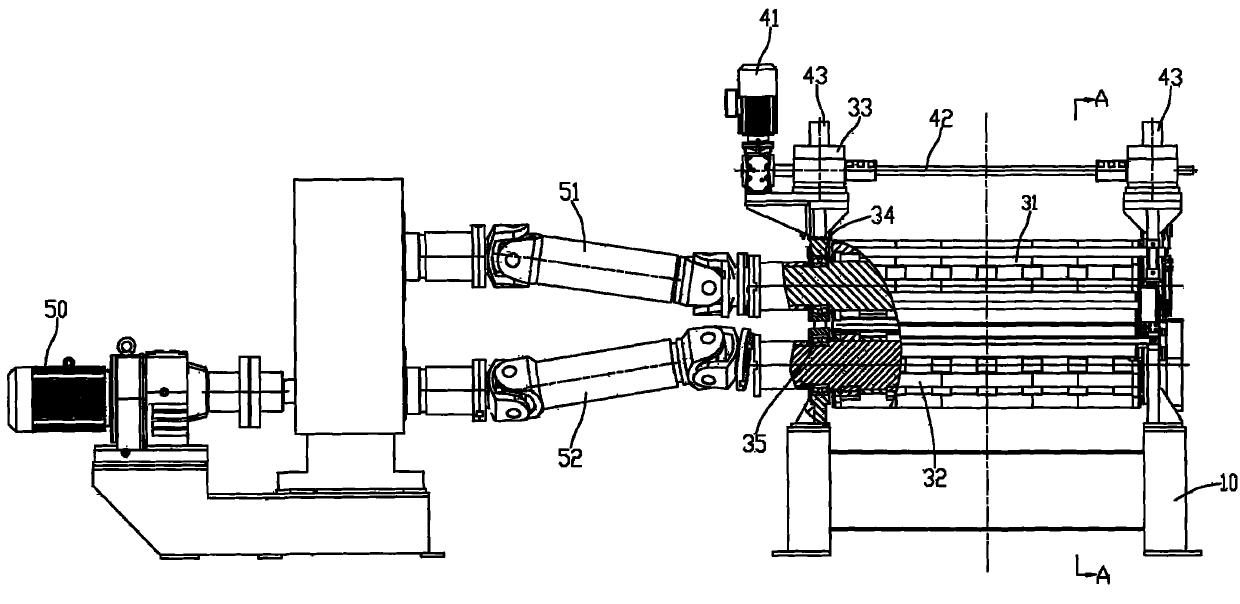

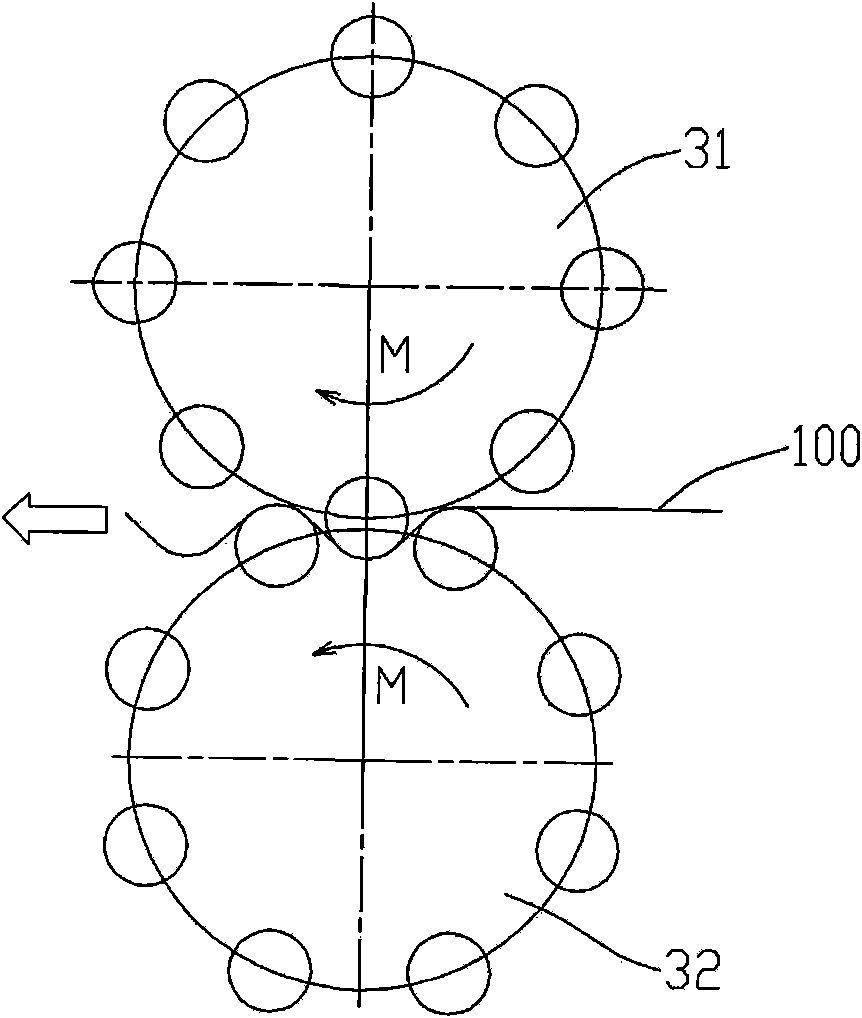

[0017] See figure 1 and figure 2 Shown: the corrugated board forming equipment of the present invention comprises frame 10, upper conveying roller 21, lower conveying roller 22, upper forming roller 31, lower forming roller 32, lower forming roller 32 is installed on the frame 10, upper forming roller 31 is installed on an adjustment sliding seat 33, and the adjustment sliding seat 33 is connected with the lifting mechanism at the same time. Speed reducer 43 links to each other, and speed reducer 43 then links to each other with adjustment slide seat 33.

[0018] A power input unit 50 is provided on one side of the frame 10, and the power input unit 50 simultaneously drives the upper forming roller 31 and the lower forming roller 32 to rotate in opposite directions through two univer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com