Manipulator device for producing rhinestones

A manipulator and rhinestone technology, which is applied in the field of manipulator devices for auxiliary rhinestone production, achieves the effects of high yield, improved production efficiency and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

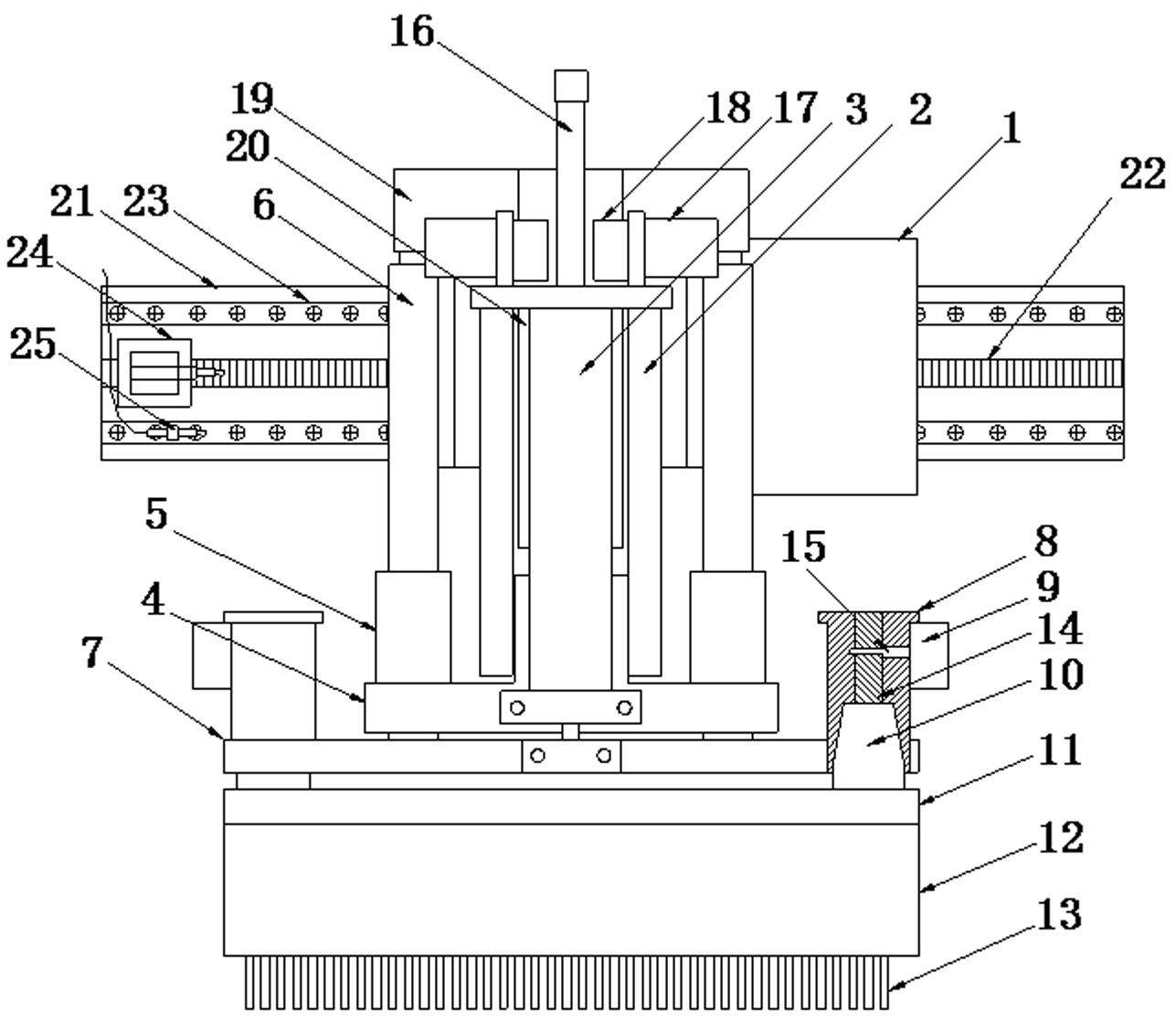

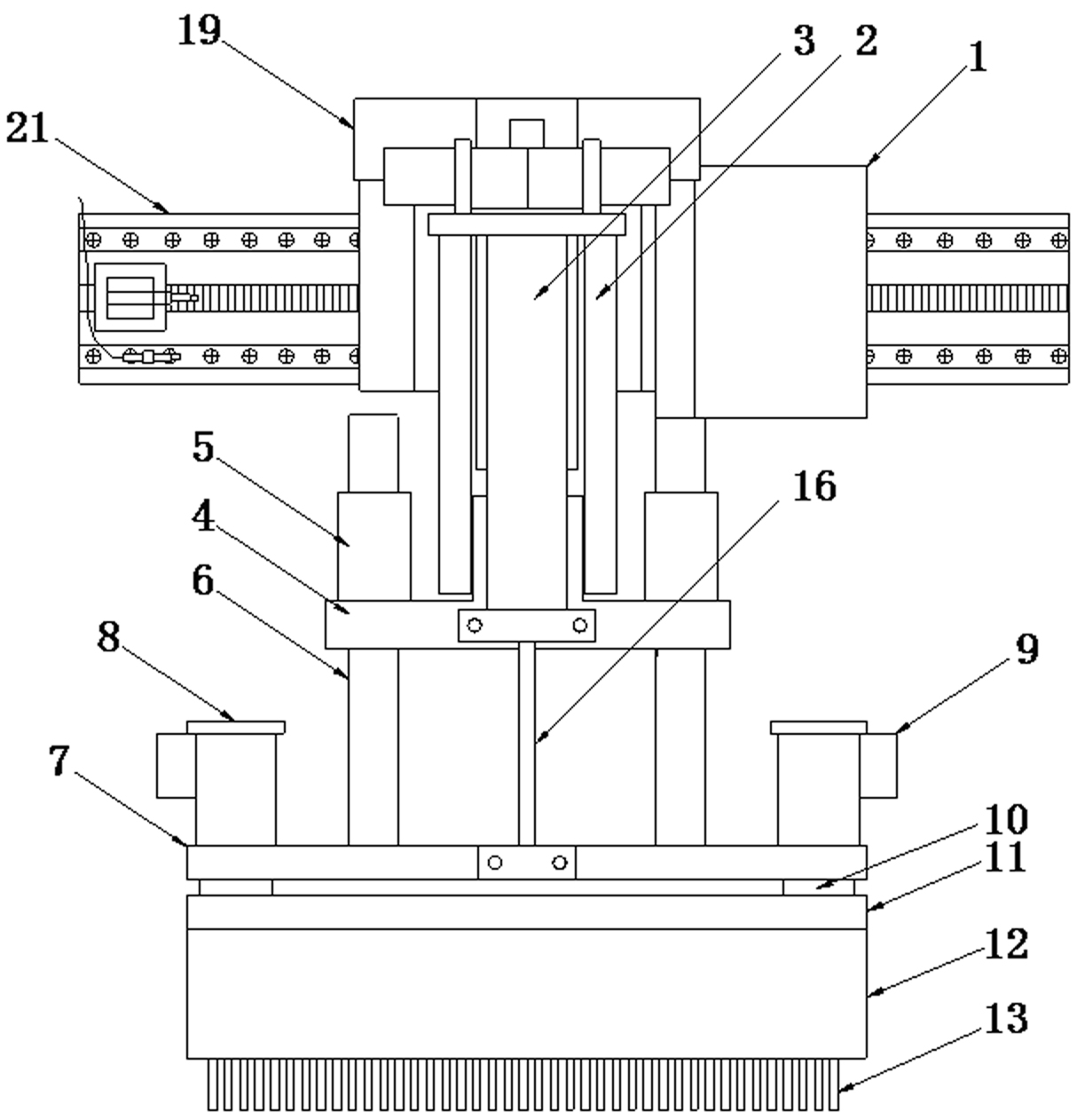

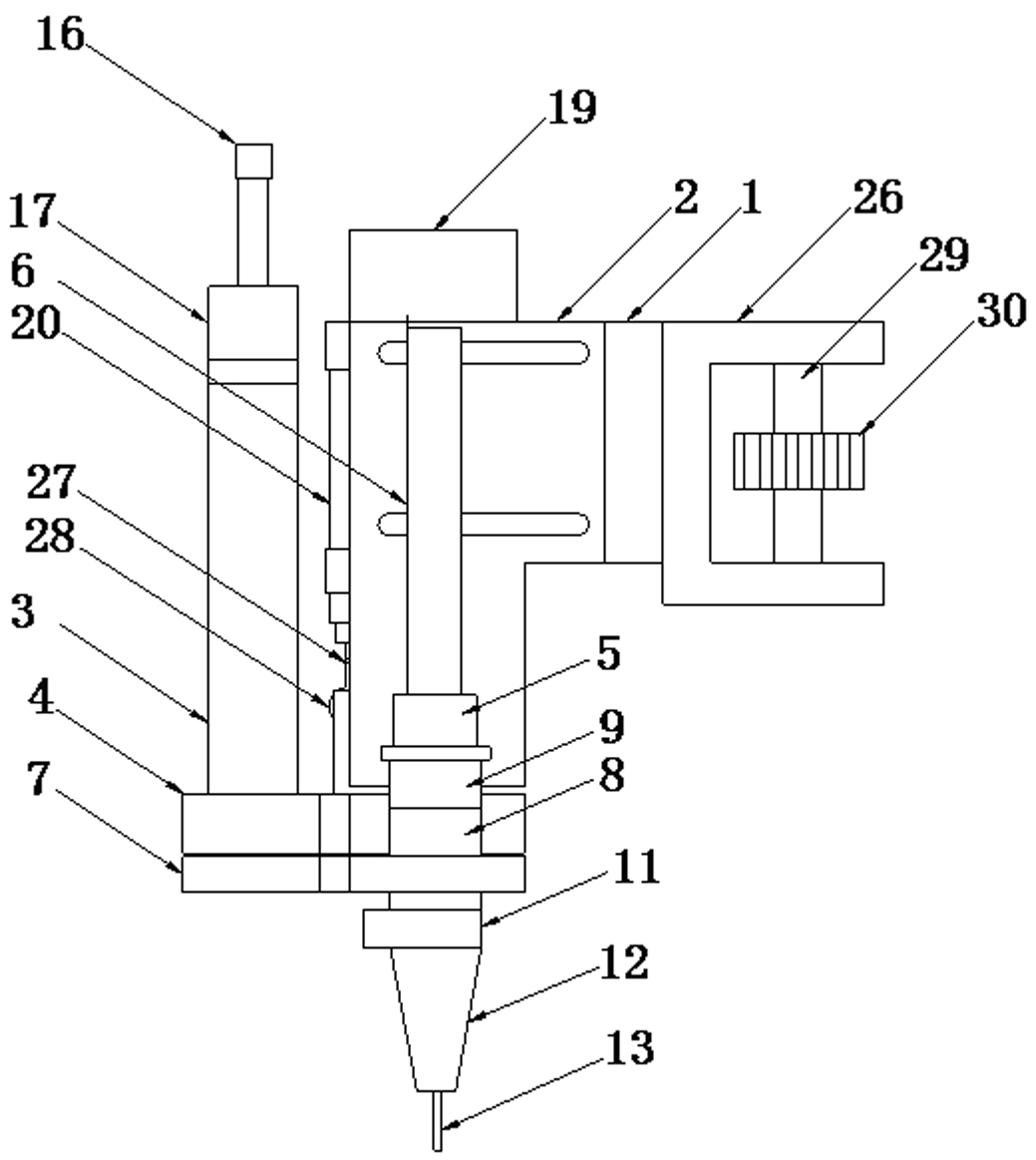

[0036] Embodiment 1: as figure 1 with Image 6 As shown in the figure, a manipulator device for rhinestone production is used for a series of rough rhinestone processing and production work such as connecting rough rhinestones in series, grinding and polishing hemispheres, docking semi-finished rough rhinestones, and grinding and polishing the other hemisphere. Auxiliary device, it comprises guide rail 21, manipulator and fixture, and manipulator is provided with a base 1, and base 1 is provided with a pair of support 2 that goes up and down, and above two supports 2 is provided with a cover plate 19 on base 1, cover plate 19 and two supports 2 forming an inverted "U" shape, the inner upper end of the inverted "U" shape is provided with a turning cylinder 20, and the turning cylinder 20 is fixed on the cover plate 19. The outlet of the front end of the inverted "U" shape is hinged with a turning movable plate 4, and the turning movable plate 4 is hinged with a drive ring 28, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com