Ceiling powder paint and preparation method thereof

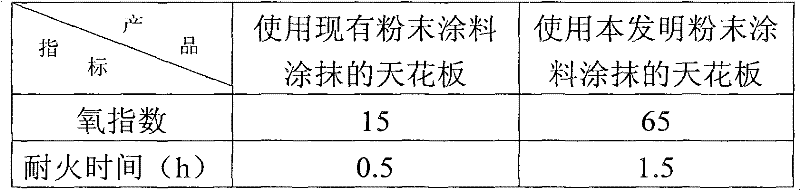

A technology for powder coatings and ceilings, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as difficulty in adapting to the layering requirements of powder coatings, inability to adapt to fire protection and decorative requirements, and inability to meet decorative functions. Achieve the effect of preventing the generation and possible spread of flames, improving fire performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

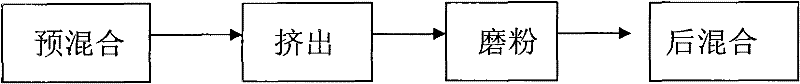

[0062] Follow the steps below to prepare powder coatings for ceilings (e.g. figure 1 shown):

[0063] In the first step, the raw materials of the following formula are premixed:

[0064] Carboxyl-terminated unsaturated polyester resin 24%

[0065] Epoxy 20%

[0066]Titanium dioxide 30%

[0067] Antimony trioxide 3%

[0068] Decabromodiphenyl ether 15%

[0069] Melamine 4%

[0070] Physical matting agent 2%

[0071] Brightener 1%

[0072] Leveling agent 1%;

[0073] Among them, the physical matting agent adopts a high melting point salt matting accelerator, specifically SA2165A produced by Lu'an Jietongda Chemical Co., Ltd., which is commercially available, and the brightener adopts acrylic acid copolymer, which is specifically produced by Fenghua Nanhai Pharmaceutical Group Co., Ltd. 701B, leveling agent adopts methyl acrylate produced by Shanghai Yuanhe Chemical Co., Ltd.;

[0074] In the second step, the pre-mixed raw materials are mixed and evenly dispersed with a...

Embodiment 2

[0082] Follow the steps below to prepare powder coatings for ceilings (e.g. figure 1 shown):

[0083] In the first step, the raw materials of the following formula are premixed:

[0084] Carboxyl-terminated unsaturated polyester resin 20%

[0085] Epoxy 26%

[0086] Titanium dioxide 33%

[0087] Antimony trioxide 5%

[0088] Decabromodiphenyl ether 10%

[0089] Melamine 3%

[0090] Physical matting agent 1.4%

[0091] Brightener 0.8%

[0092] Leveling agent 0.8%;

[0093] Among them, the physical matting agent adopts high melting point salt matting accelerator, specifically the commercially available Fenghua Nanhai Pharmaceutical Group Co., Ltd. 388-1, and the brightener adopts acrylic acid copolymer, specifically using Wuxi Wanli Chemical Co., Ltd. 931, leveling agent Ethyl acrylate produced by Shanghai Yuanhe Chemical Co., Ltd.;

[0094] In the second step, the pre-mixed raw materials are mixed and evenly dispersed with a single-screw reciprocating damping extruder...

Embodiment 3

[0098] Follow the steps below to prepare powder coatings for ceilings (e.g. figure 1 shown):

[0099] In the first step, the raw materials of the following formula are premixed:

[0100] Carboxyl-terminated unsaturated polyester resin 30%

[0101] Epoxy 23%

[0102] Titanium dioxide 28%

[0103] Antimony trioxide 3%

[0104] Decabromodiphenyl ether 10%

[0105] Melamine 2%

[0106] Physical matting agent 1.6%

[0107] Brightener 1.2%

[0108] Leveling agent 1.2%;

[0109] Among them, the physical matting agent adopts high melting point salt matting accelerator, specifically T-335 produced by Dongguan Zhongtian New Material Co., Ltd., and the brightener adopts acrylic acid copolymer, specifically 701B produced by Fenghua Nanhai Pharmaceutical Group Co., Ltd. The leveling agent is methyl acrylate produced by Shanghai Yuanhe Chemical Co., Ltd.;

[0110] In the second step, the pre-mixed raw materials are mixed and evenly dispersed with a single-screw reciprocating dampi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com