Ball valve

A technology for ball valves and valve stems, applied to valve details, valve devices, valve housing structures, etc., can solve the problems of small elastic force and shortened service life of valves, and achieve the effect of increasing elasticity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

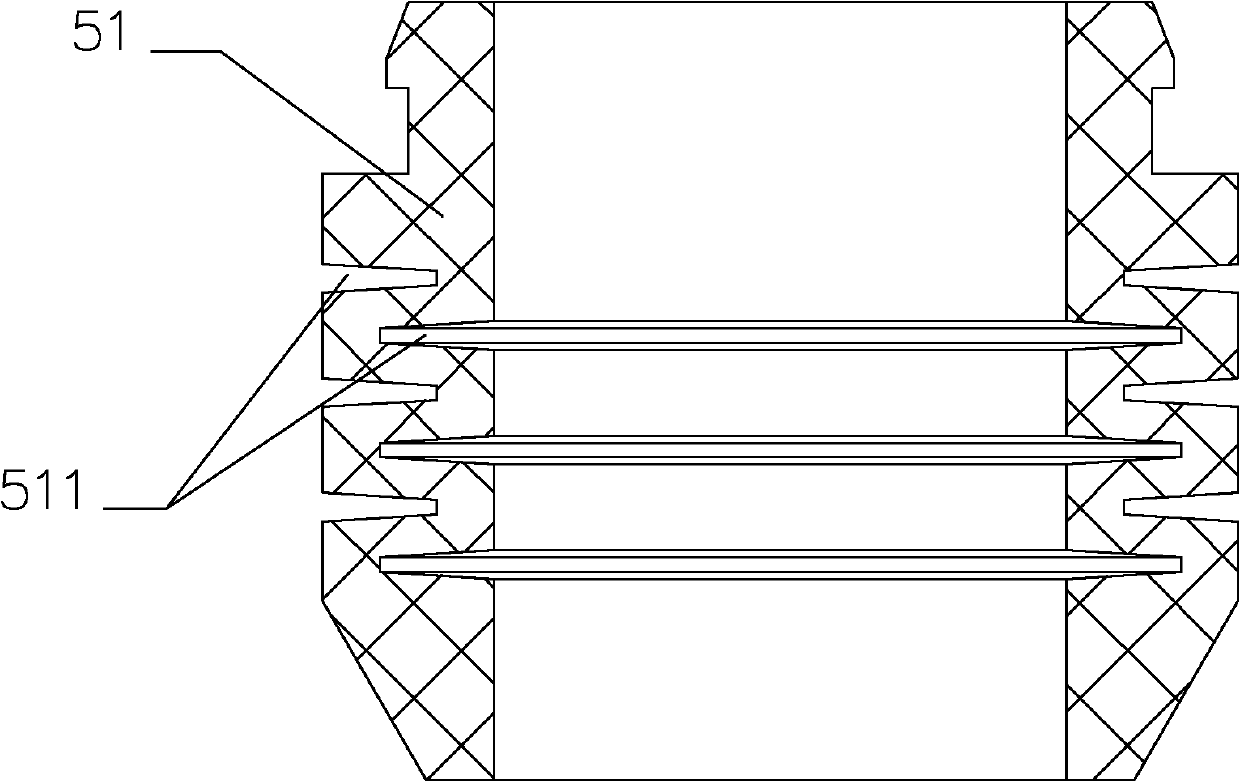

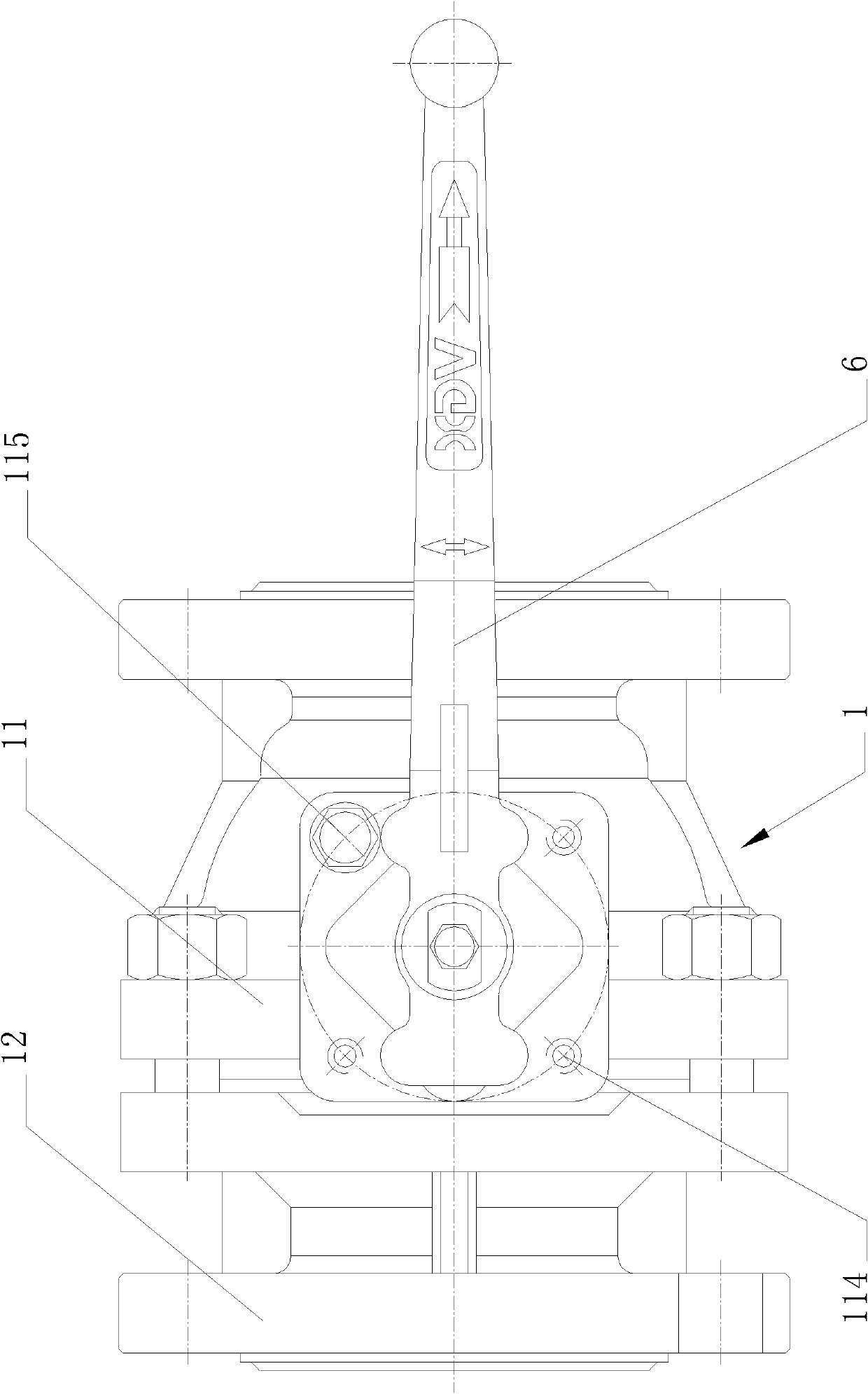

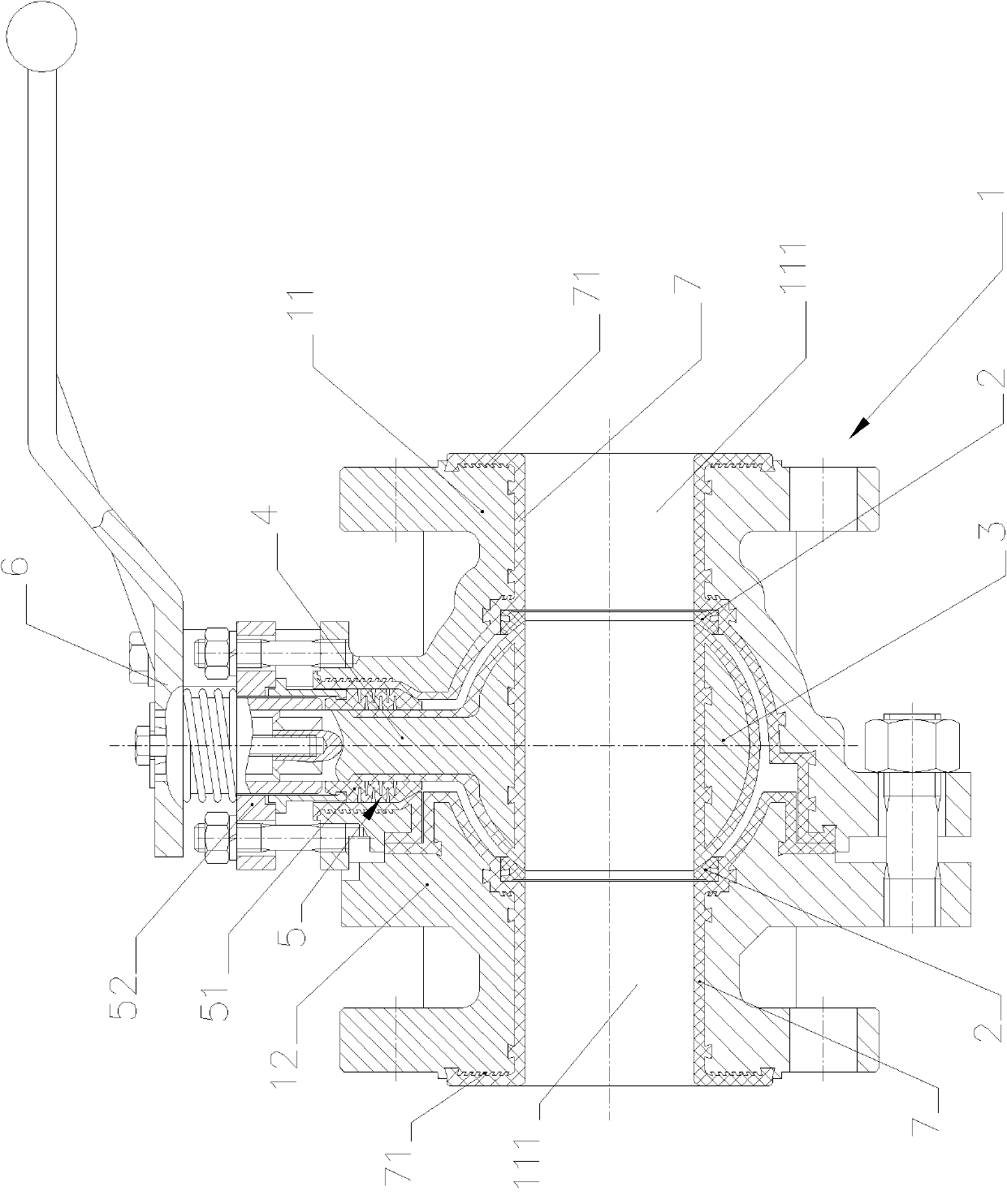

[0013] Embodiments of the present invention will be further described below in conjunction with accompanying drawings: Figure 1 to Figure 5 As shown, the present invention is a ball valve, which includes a valve body 1, a valve seat 2, a valve core 3, a valve stem 4, a packing mechanism 5 and an operating mechanism 6, and the valve seat 2 and the valve core 3 are placed Inside the valve body 1 and the valve core 3 closely fits with the valve seat 2, one end of the valve rod 4 is placed inside the valve body 1 and fixedly connected with the valve core 3, and the other end is placed outside the valve body 1 and connected with the operating mechanism 6, The packing mechanism 5 includes a packing 51 and a packing gland 52. The packing 51 is placed in the valve body 1 and sleeved outside the valve stem 4, and the inner and outer walls of the packing 51 are respectively connected to the valve body 1 and the valve body. The rod 4 is closely fitted, the packing gland 52 is sleeved ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com