Optical coherence tomography system correction method

A correction method and correction data technology, applied in the field of OCT system correction, can solve problems such as the operation of the galvanometer drive signal and the nonlinear distortion of the OCT image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

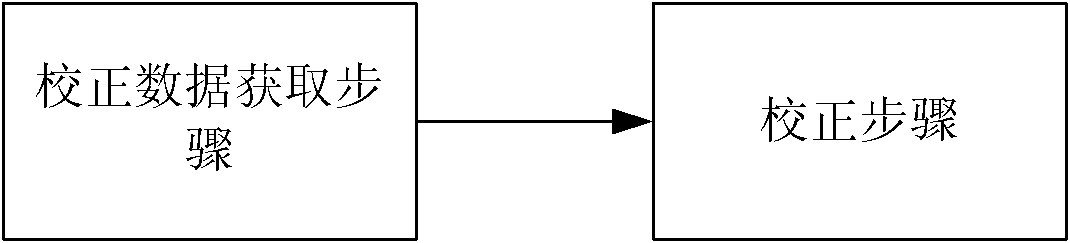

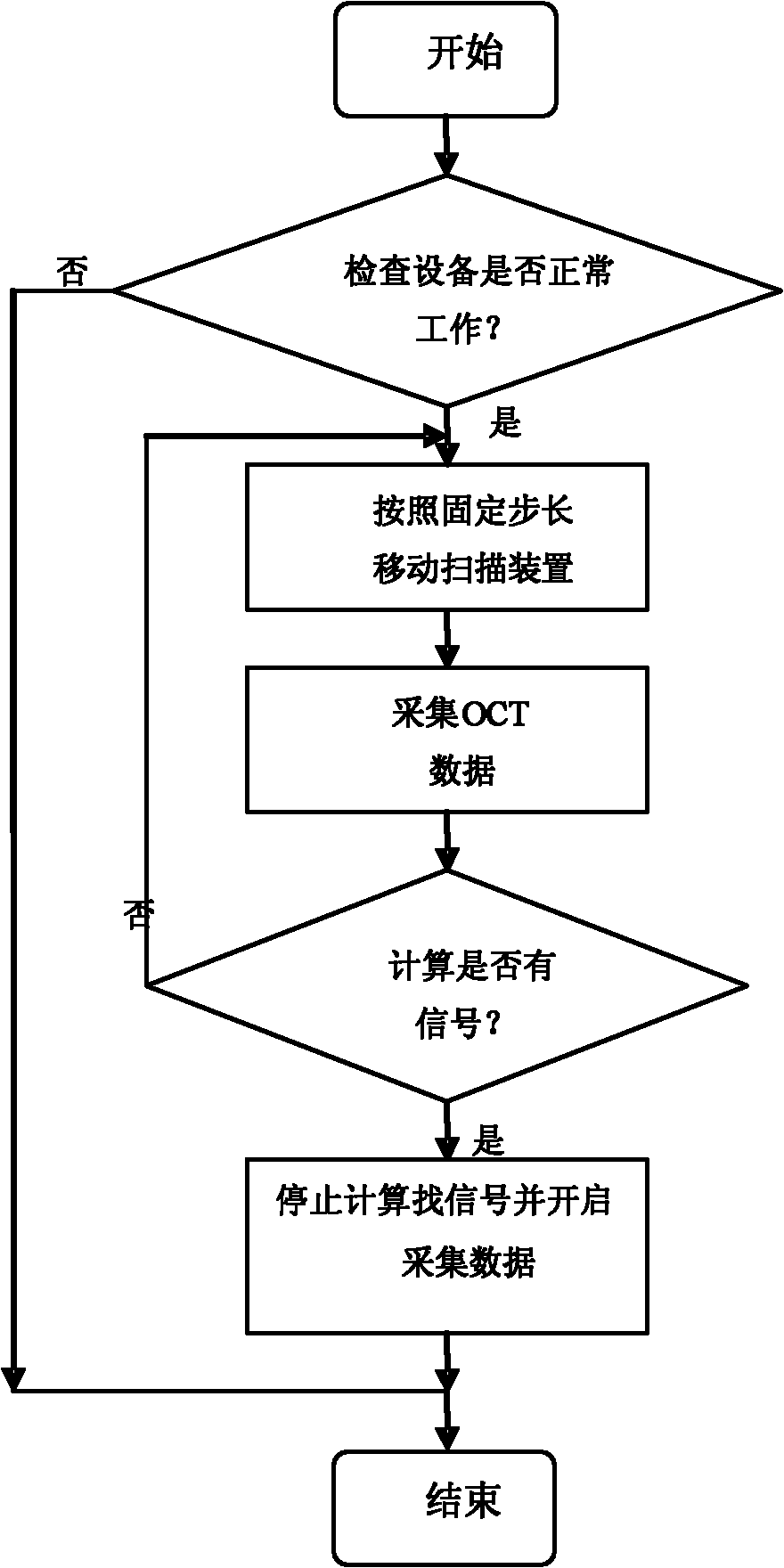

[0019] Such as figure 2 As shown, an OCT system calibration method includes the following steps: a calibration data acquisition step: the OCT system scans a reference slide to obtain the relationship function between the thickness value and the depth position at different positions; and, the calibration step: according to the The relationship function between the thickness value and the depth position is used to correct the acquired detection data.

[0020] Wherein, the transparent reference glass slide with a thickness of ten microns is thicker than the resolution of the OCT system. The OCT system automatically searches for the signals on the upper and lower surfaces of the reference slide. When both layers of signals enter the picture, it starts to collect, and slowly moves the height of the sample to measure again. Repeatedly, a series of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com