Full-automatic measuring device of load tank

A technology of measuring devices and load boxes, applied in measuring devices, measuring electrical variables, instruments, etc., can solve problems such as unfavorable work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Markings in the attached drawings:

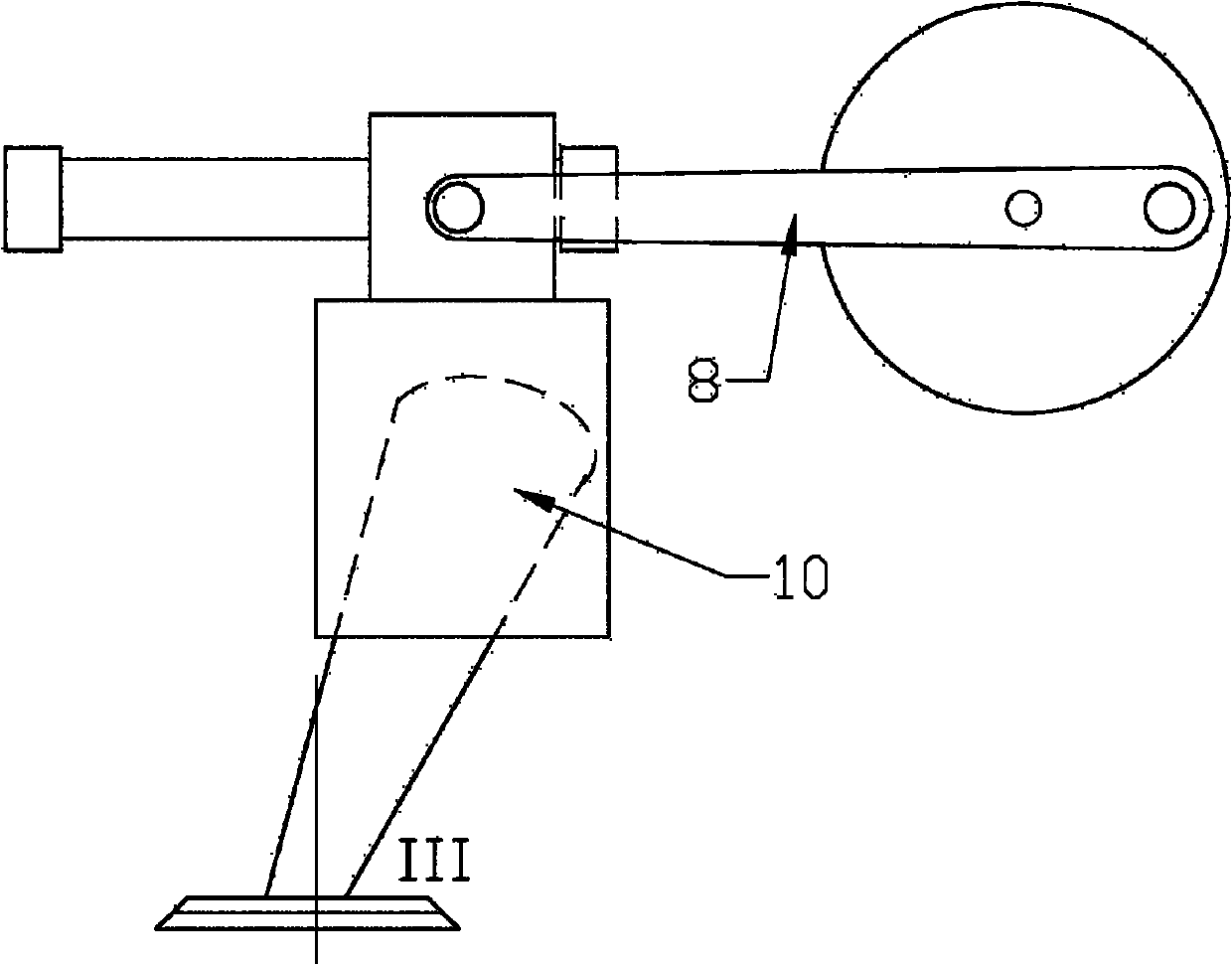

[0012] In the accompanying drawings, 1-switching circuit, 2-load box, 3-adjusting mechanism, 4-limiting pile, 5-sliding rod, 6-turntable, 7-motor, 8-linkage rod, 9-moving cabin, 10 - Dial switch.

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

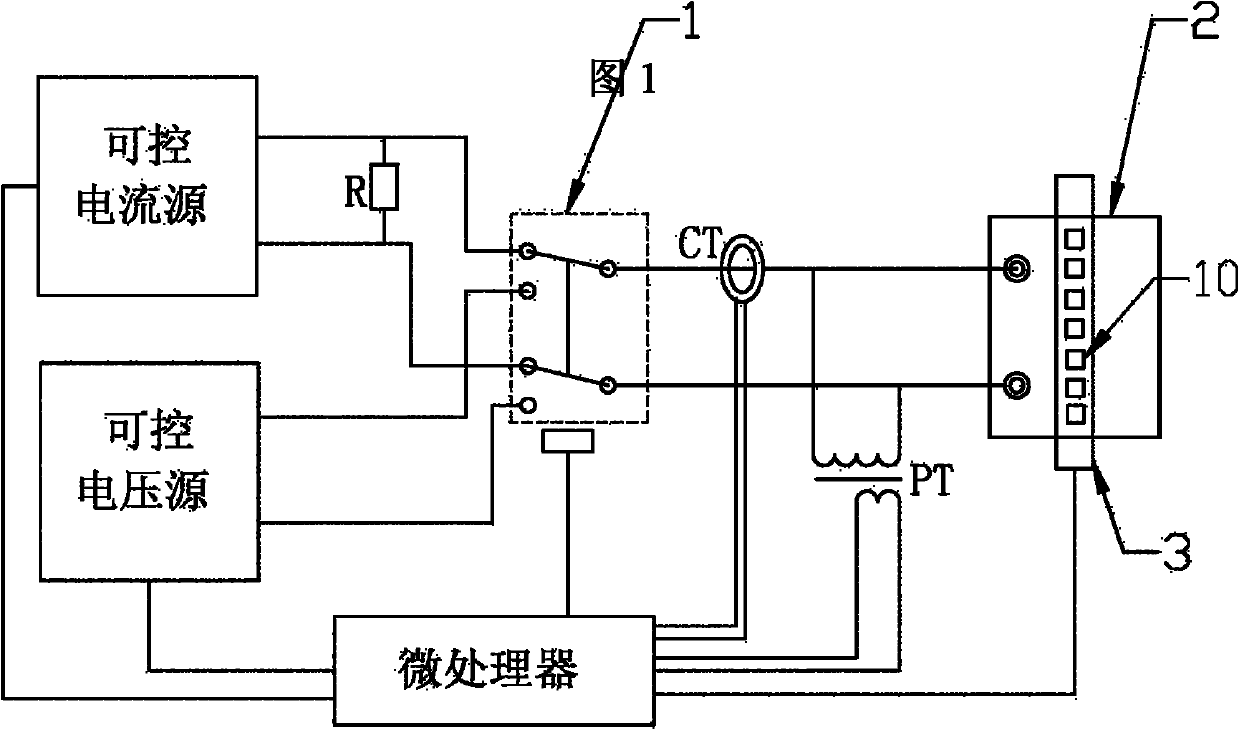

[0014] as attached figure 1 It is the principle diagram of automatic measurement of the load box. The controllable current source and controllable voltage source in the figure can supply power to the load box respectively. The microprocessor is the main control device, which can analyze, store, record and print the data in the whole process. R is the protection The protection resistance of the current source, the switching circuit 1 switches the controllable current source or the controllable voltage source to supply power to the load box, and the high-precision CT and high-precision PT measure the real-time current an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com