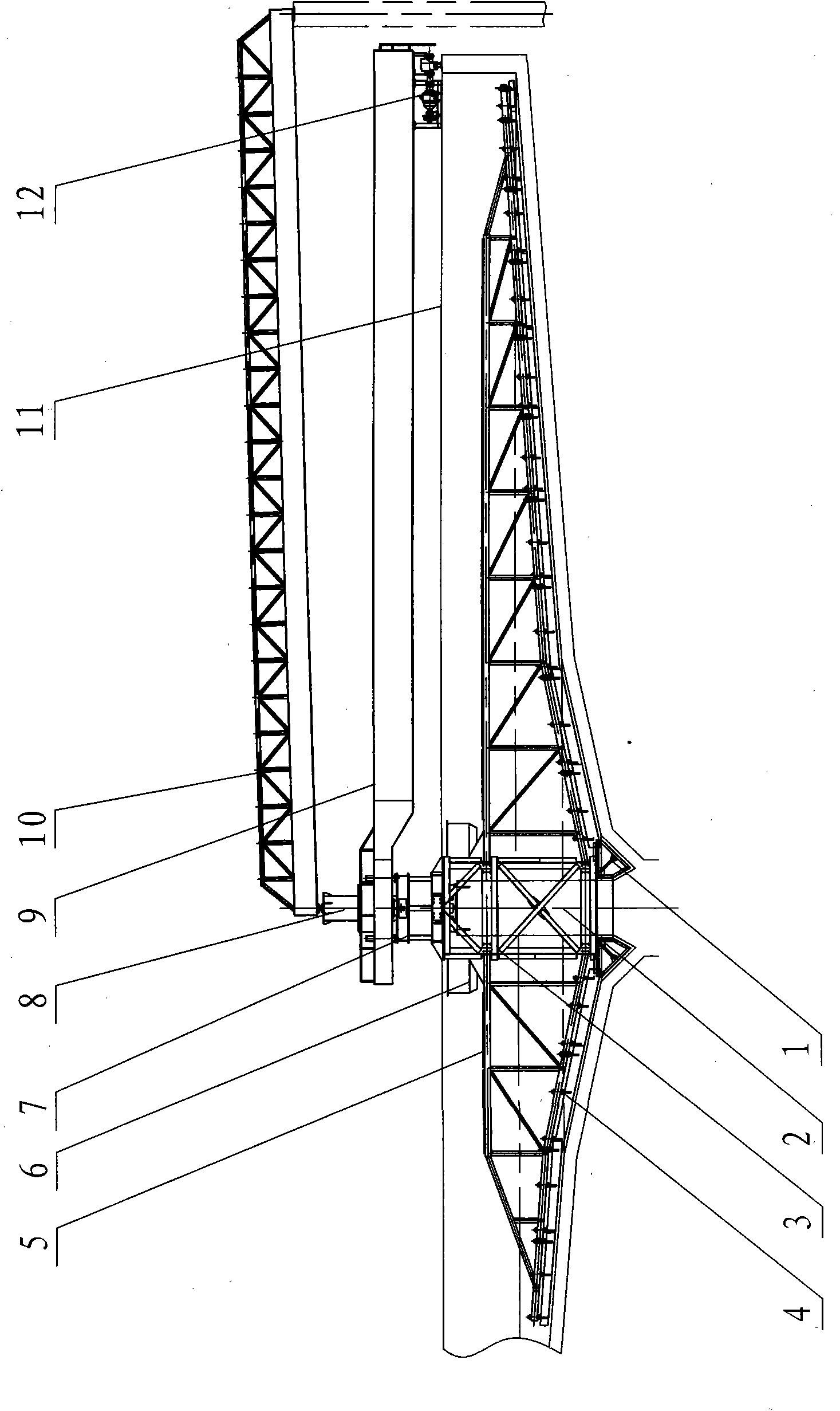

Peripheral transmission center automatic rake-lifting thickener

A technology of peripheral transmission and concentrator, which is applied in the direction of settling tanks, feeding/discharging devices of settling tanks, chemical instruments and methods, etc., which can solve problems such as inability to lift rakes, derailment of rollers, and reduced service life of rubber wheels. Achieve the effects of improving concentration efficiency, avoiding displacement, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

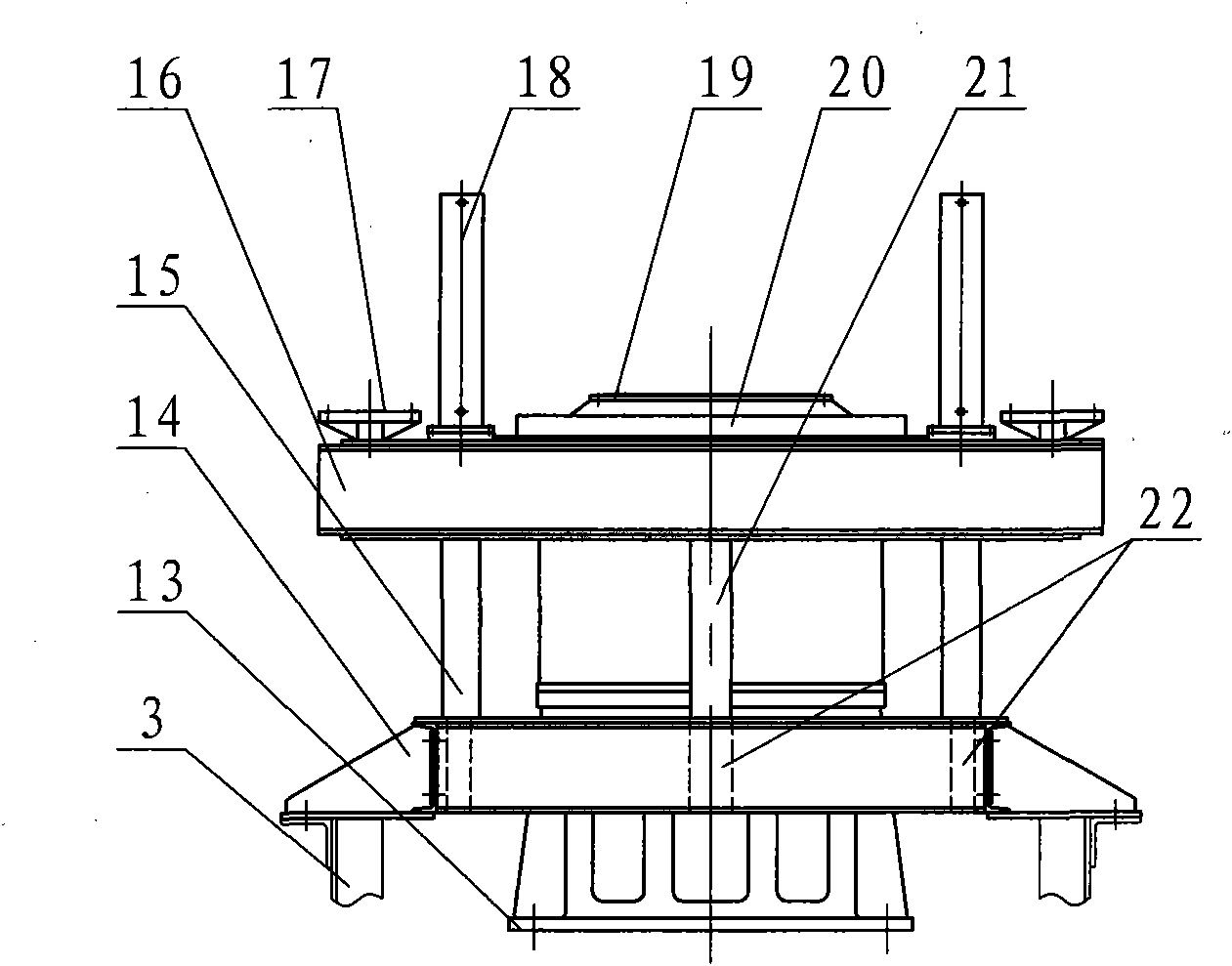

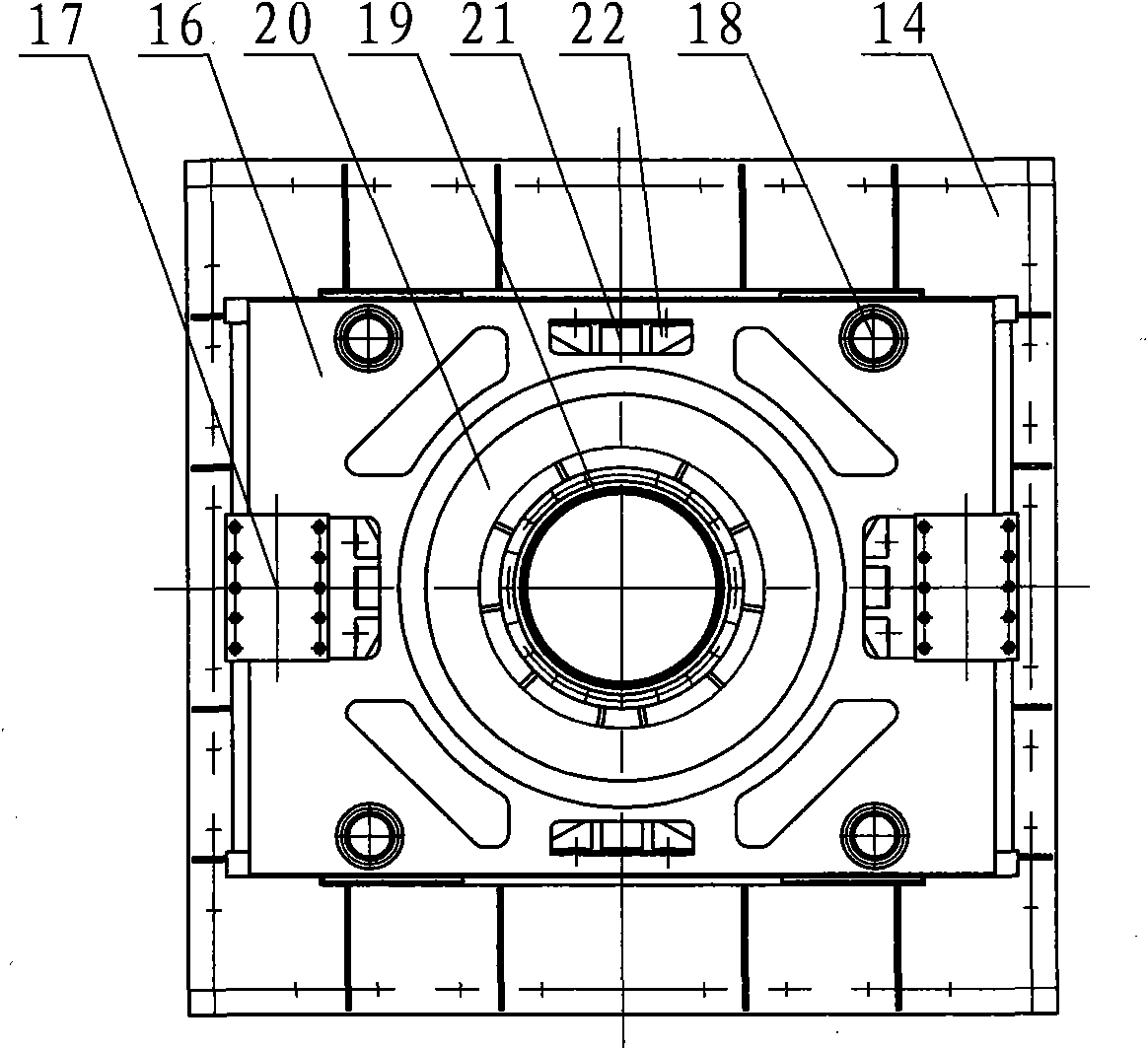

[0018] Such as figure 2 As shown, the central support 7 is composed of a fixed support 13, a seat ring 19, a slewing support 20, a rotating frame 16 and a sliding frame 14;

[0019] The fixed support 13 is columnar and plays the role of carrying the concentrator; the seat ring 19 is installed on the fixed support 13 and connected with the inner ring of the slewing support 20;

[0020] The slewing bearing 20 is a standard part, which is composed of an inner ring, a ball and an outer ring, and the inner ring and the outer ring can rotate freely;

[0021] The swivel frame 16 is connected with the outer ring of the slewing bearing 20, and four sliding keys 21 and four lifting cylinders 18 are evenly distributed on the periphery of the upper plane. Only the sliding key 21 is fixed on the side of the periphery of the rotating frame 16; the periphery of the sliding frame 14 is evenly distributed with four chutes 22, and the chute is connected up and down, and its position correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com